Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023

In the rapidly evolving landscape of precision manufacturing, the importance of advanced technological solutions cannot be overstated. Steel laser cutting has emerged as a pivotal process that enhances the accuracy, efficiency, and versatility of manufacturing operations. According to a recent industry report, the global market for laser cutting machines is projected to reach $5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth underscores the increasing demand for high-precision cutting techniques in various sectors, including automotive, aerospace, and electronics.

Steel laser cutting stands out for its ability to produce intricate designs with minimal material wastage. With advancements in laser technology, manufacturers are now able to achieve tolerances as tight as ±0.05 mm. This level of precision not only reduces the need for additional machining processes but also enhances the overall quality of the final product. Furthermore, the integration of automation and smart technologies in laser cutting systems has significantly optimized production workflows, allowing for quicker turnaround times and reduced operational costs.

As we delve deeper into the significance of steel laser cutting in 2023, it becomes evident that this innovation is not merely a trend but a fundamental necessity for organizations aiming to remain competitive in the precision manufacturing arena. By leveraging steel laser cutting technologies, manufacturers can ensure superior product quality while simultaneously reducing production inefficiencies, ultimately driving growth and sustainability in their operations.

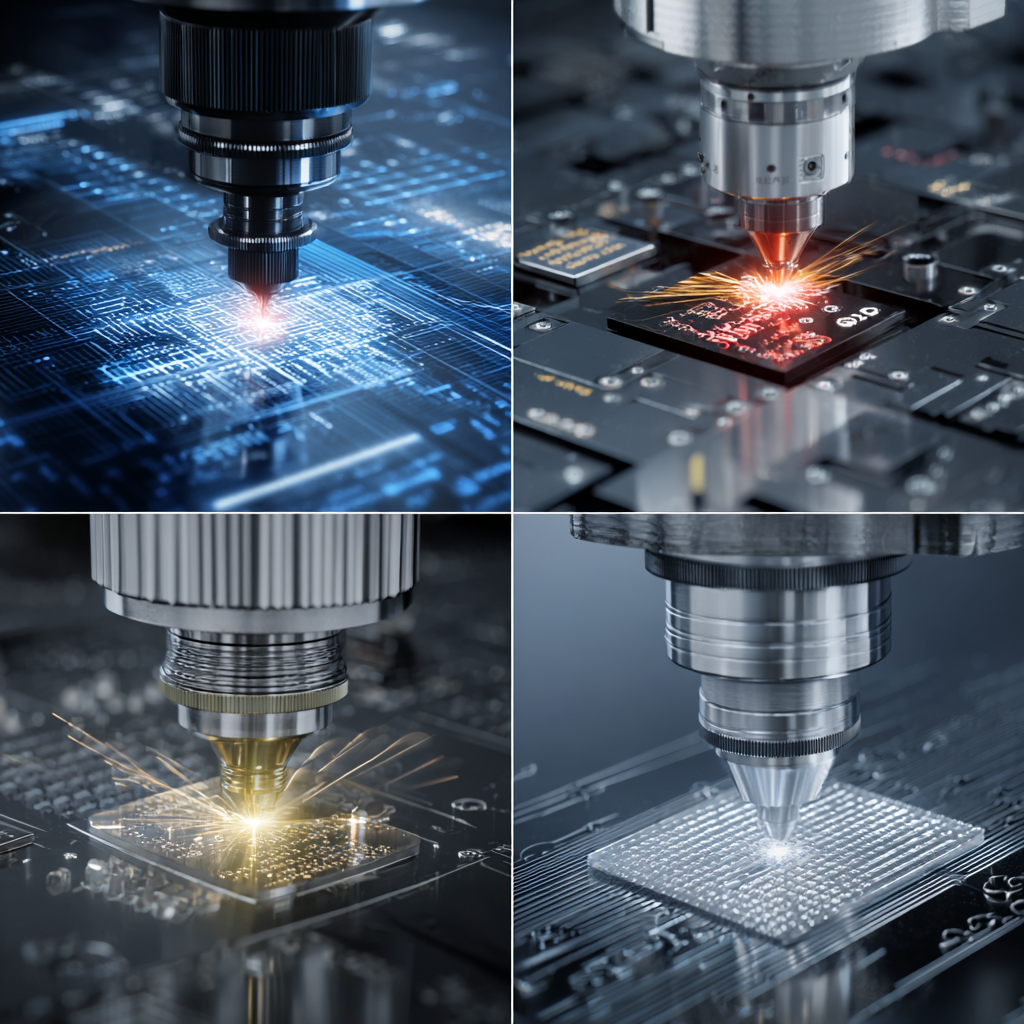

The Fundamentals of Steel Laser Cutting Technology

Steel laser cutting technology has become a cornerstone of precision manufacturing in 2023. This advanced method utilizes high-powered lasers to cut steel with incredible accuracy and speed. By focusing a laser beam on the material, manufacturers can achieve intricate designs and tight tolerances that are difficult to replicate with traditional cutting methods. The precision of laser cutting not only enhances the quality of the finished product but also minimizes material waste, making it an economical choice for various industries.

Steel laser cutting technology has become a cornerstone of precision manufacturing in 2023. This advanced method utilizes high-powered lasers to cut steel with incredible accuracy and speed. By focusing a laser beam on the material, manufacturers can achieve intricate designs and tight tolerances that are difficult to replicate with traditional cutting methods. The precision of laser cutting not only enhances the quality of the finished product but also minimizes material waste, making it an economical choice for various industries.

Tips: When utilizing steel laser cutting, it's essential to select the appropriate laser type based on the material thickness and complexity of the design. Regular maintenance of the laser equipment is crucial to ensure consistent performance and longevity. Additionally, investing in employee training can significantly enhance operational efficiency and safety during the cutting process.

As the manufacturing landscape evolves, the integration of steel laser cutting technology is increasingly important. This technique allows for rapid prototyping and scalability, enabling manufacturers to meet changing market demands efficiently. By leveraging laser cutting, businesses can stay competitive while producing high-quality, precision-engineered components.

Key Advantages of Laser Cutting in Precision Manufacturing

In 2023, laser cutting technology has become indispensable in precision manufacturing, with its advantages proving vital for industries that prioritize accuracy and efficiency. According to a recent market analysis by Research and Markets, the global laser cutting market is projected to reach $5 billion by 2026, underscoring the growing reliance on this technology. One key advantage of laser cutting is its unmatched precision, with the ability to cut materials to tolerances as tight as ±0.1 mm. This level of accuracy is crucial in sectors such as aerospace and automotive, where even the smallest deviation can lead to significant issues in performance and safety.

Additionally, laser cutting stands out for its versatility and material efficiency. It can handle a wide range of materials, from steel and aluminum to intricate composites, while minimizing waste. A study by the Manufacturing Institute found that manufacturers using laser cutting report up to 30% reductions in material waste compared to traditional cutting methods. This not only lowers operational costs but also aligns with sustainability goals as the industry moves towards greener practices. The combination of precision and efficiency solidifies laser cutting's role as a fundamental technology in modern manufacturing landscapes.

Applications of Steel Laser Cutting in Various Industries

Steel laser cutting technology has become a cornerstone in various industries due to its unmatched precision and versatility. In the automotive sector, for instance, laser cutting is critical for producing intricate components with tight tolerances, ensuring that parts fit together seamlessly and function safely. The automotive industry benefits from the ability to cut different types of metals quickly, allowing for rapid prototyping and reduced lead times in production. Additionally, the lightweight characteristics of components produced through laser cutting contribute to overall vehicle efficiency and improved fuel economy.

In the construction industry, steel laser cutting is essential for fabricating structural elements and architectural features. This technology allows for the creation of complex designs that would be difficult or impossible to achieve with traditional cutting methods. The precision of laser cutting minimizes material waste, optimizing costs and supporting sustainable practices in construction. Furthermore, as industries evolve and demand for customized solutions increases, the applications of steel laser cutting are likely to expand, driving innovation and efficiency across various manufacturing sectors.

Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023 - Applications of Steel Laser Cutting in Various Industries

| Industry | Application | Precision Level | Advantages |

|---|---|---|---|

| Automotive | Component Fabrication | High Precision | Reduced Waste, Fast Processing |

| Aerospace | Structural Parts | Ultra-High Precision | Enhanced Safety, Lightweight Designs |

| Construction | Steel Framework | Moderate Precision | Durability, Time Efficiency |

| Medical Devices | Surgical Instruments | High Precision | Specificity, Clean Cuts |

| Electronics | Circuit Board Traces | Extreme Precision | Precision Cutting, Versatility |

Comparing Steel Laser Cutting with Traditional Cutting Methods

In 2023, steel laser cutting has emerged as a game changer in precision manufacturing, particularly when compared to traditional cutting methods. Traditional techniques, such as plasma cutting or mechanical sawing, often result in larger heat-affected zones, leading to distortion and rough edges. Laser cutting, however, offers an unparalleled level of accuracy, even for intricate designs. This precision significantly reduces the need for secondary machining processes, thereby streamlining production and enhancing overall efficiency.

**Tips for Optimizing Laser Cutting:**

1. Ensure proper material setup to enhance laser focus and minimize waste.

2. Regularly maintain and calibrate your laser cutting equipment to ensure maximum efficiency and precision throughout the cutting process.

Moreover, the versatility of laser cutting technology allows manufacturers to work with various materials beyond steel, including aluminum and plastics. Unlike traditional methods that may require different tools for different materials, laser cutting systems can quickly adapt, cutting costs and time significantly. This flexibility, combined with superior cut quality, solidifies laser cutting’s place as an essential technique in modern manufacturing.

Comparison of Steel Laser Cutting and Traditional Cutting Methods in Precision Manufacturing (2023)

Future Trends in Steel Laser Cutting Technology for 2023

As steel laser cutting continues to evolve, its significance in precision manufacturing grows immensely. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $4.2 billion by 2026, expanding at a CAGR of 5.6% from 2021. This growth is driven by advancements in laser technology, including fiber lasers, which offer greater efficiency and precision than traditional CO2 lasers. In 2023, manufacturers can expect enhanced capabilities in cutting complex geometries with minimal material waste, making laser cutting not only an economical choice but also a sustainable one.

Future trends indicate a shift towards automation and integration of artificial intelligence in laser cutting systems. A recent study from Research and Markets highlights that AI-enabled laser cutting machines can optimize cutting paths in real time, significantly improving cycle times. The integration of Industry 4.0 practices further ensures real-time data analytics, allowing for predictive maintenance and reducing downtime. As these technologies advance, businesses adopting steel laser cutting will not only enhance their manufacturing precision but also gain a competitive edge in an increasingly automated environment.

Related Posts

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained