How to Start Laser Engraving Your Own Unique Designs at Home

Embarking on the journey of laser engraving can open up a world of creativity and personalization for hobbyists and entrepreneurs alike. With its ability to transform ordinary materials into unique designs, laser engraving has become increasingly popular among DIY enthusiasts. According to industry expert Dr. Emily Carter, "Laser engraving is not just a technical skill, but a form of artistic expression that allows individuals to bring their visions to life."

Whether you're looking to create custom gifts, personalized home décor, or artistic works, understanding the fundamentals of laser engraving is essential. This innovative technology empowers you to design intricate patterns on various materials, ranging from wood and acrylic to leather and metal. As you venture into this exciting field, you'll discover the satisfaction of crafting products that reflect your personal style and meet the needs of your customers. By mastering the techniques of laser engraving, you can unlock endless possibilities and establish your own niche in the creative landscape.

The process may seem daunting at first, but with the right tools and knowledge, starting your own laser engraving projects at home can be both achievable and rewarding. Prepare to dive into a realm of creativity where your unique designs can flourish, as you transform mundane objects into cherished pieces through the art of laser engraving.

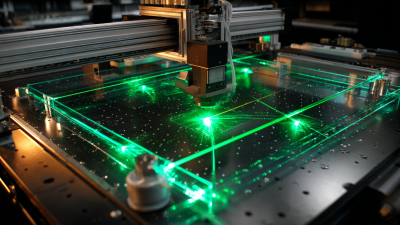

Understanding Laser Engraving: Technology and Applications Overview

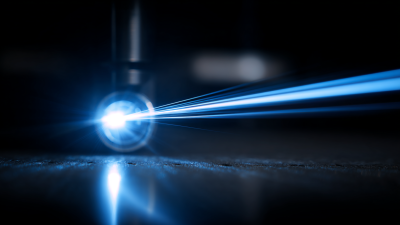

Laser engraving is an innovative process that uses focused laser beams to etch designs onto various materials. This technology is becoming increasingly accessible for home users, allowing for a wide range of creative applications. From personalizing gifts to creating unique art pieces, understanding the mechanics behind laser engraving can help hobbyists and small business owners leverage this tool effectively. Materials commonly used in laser engraving include wood, glass, acrylic, and leather, each offering different textures and finishes that enhance the final product.

Tips: Before starting your laser engraving projects, familiarize yourself with the settings and capabilities of your laser machine. It's crucial to experiment with different power levels and speed settings to obtain optimal results for various materials. Additionally, practice on scrap pieces before committing to your intended design, as this will help you better understand how the machine interacts with different surfaces.

Moreover, the software used to create your designs plays a vital role in the engraving process. Opt for user-friendly programs that allow easy manipulation of graphics and text. Ensuring that your designs are compatible with your laser cutter will save you time and reduce frustration. Embracing these techniques will ensure a smoother workflow and elevate the quality of your engravings, paving the way for innovative and distinct creations at home.

Essential Equipment for Home Laser Engraving Setup

Setting up a home laser engraving setup requires essential equipment to ensure efficiency and high-quality results. According to a report from the Laser Institute of America, the global laser engraving market is projected to grow significantly, with a compound annual growth rate (CAGR) of 7.6% from 2021 to 2026. This growth highlights not only an expanding interest in laser engraving but also the importance of investing in the right tools to stay competitive in this burgeoning field.

The cornerstone of any laser engraving setup is the laser engraver itself, which should be selected based on the materials you intend to work with, such as wood, acrylic, or glass. Additionally, software is crucial for creating and modifying designs; many users opt for vector design software that can directly interface with the engraving machine. A reliable exhaust system is also essential to manage smoke and particulates produced during the engraving process, ensuring a safe and clean working environment. Industry reports indicate that a proper ventilation system can improve air quality and enhance the longevity of the equipment, making it a critical aspect of your setup.

Furthermore, investing in safety gear, such as goggles and gloves, is vital to protect yourself during the engraving process. With a growing number of hobbyists and small businesses entering the laser engraving market, having the right equipment can significantly influence the quality of your designs and the success of your projects. A comprehensive understanding of essential equipment not only streamlines the engraving process but also allows you to bring your unique creative visions to life.

Choosing the Right Materials for Your Laser Engraving Projects

Choosing the right materials for your laser engraving projects is crucial for achieving the best results. Different materials respond uniquely to laser engraving, which can affect the clarity, depth, and overall appearance of your design. Common materials you might consider include wood, acrylic, glass, and metal. Each material has its pros and cons; for instance, wood offers a warm aesthetic but can produce varying results depending on its grain and type, while acrylic is known for its vibrant color options and smooth finishes.

When selecting materials, it's also important to consider the intended use of the engraved item. If you are creating functional items, such as coasters or cutting boards, you will want materials that are durable and can withstand everyday use. For decorative pieces, aesthetics may take precedence, encouraging the use of more delicate or visually striking materials. Additionally, be mindful of the laser's wattage as this influences the thickness and type of material you can effectively engrave. Experimenting with different materials will help you discover the unique characteristics and effects they bring to your engravings, ultimately allowing you to develop your own distinctive style.

Design Software Options for Creating Unique Laser Engravings

When it comes to creating unique laser engravings, the right design software can make all the difference. There are several options available that cater to both beginners and experienced users. For those just starting out, user-friendly programs often offer intuitive interfaces and drag-and-drop features, making it easier to bring your creative visions to life. These types of software typically include built-in templates and design elements, which can serve as a great foundation for custom designs.

For more advanced users, vector graphic design software can provide a wealth of tools and functionalities to take engraving projects to the next level. Such software allows for precise control over shapes, lines, and colors, enabling intricate and detailed designs. Users can create their own artwork from scratch or modify existing graphics to fit their engraving needs. Cloud-based options are also available, allowing for collaboration and easy access to designs from any device. Whichever route you choose, the software you select will ultimately shape the uniqueness and quality of your laser engravings at home.

Laser Engraving Design Software Usage

Safety Practices and Maintenance Tips for Home Laser Engraving

When embarking on a home laser engraving project, safety practices are paramount to ensure a secure and efficient workspace. According to the Laser Institute of America, approximately 5,000 laser-related incidents are reported annually, highlighting the critical importance of taking proper precautions. First, always use protective eyewear that meets ANSI Z87.1 standards to shield your eyes from harmful laser radiation. Additionally, ensure your workspace is well-ventilated. Some materials, when engraved, can release toxic fumes; for instance, engraving plastic can emit hazardous gases, making an exhaust system or fume extractor a necessity.

**Tips for Enhancing Safety:**

- Before starting, familiarize yourself with your laser engraver's operating manual to understand its features and safety protocols.

- Keep a fire extinguisher nearby as an extra precaution, as the engraving process can produce sparks, especially with flammable materials.

- Use a designated work surface that is non-combustible to prevent fires.

Maintenance of your laser engraver is equally important for longevity and effectiveness. Regularly inspect and clean the lens, mirrors, and ventilation filters to ensure optimal performance. The average lifespan of a laser tube can range between 1,000 to 2,000 hours of use; extending this lifespan is pivotal. According to a report from the American Industrial Laser Association, proper maintenance can improve not only safety but also the quality of engravings.

**Tips for Effective Maintenance:**

- Schedule routine maintenance checks based on the frequency of use, and always follow manufacturer recommendations for cleaning intervals.

- Use distilled water in water-cooled systems to prevent mineral build-up and ensure consistent cooling.

By integrating these safety practices and maintenance tips, you can enjoy a successful and safe home laser engraving experience.

How to Start Laser Engraving Your Own Unique Designs at Home - Safety Practices and Maintenance Tips for Home Laser Engraving

| Aspect | Details |

|---|---|

| Laser Type | CO2 Laser Engraver |

| Power Requirement | 110V to 240V AC |

| Safety Gear | Safety goggles, gloves, and ventilation mask |

| Maintenance Frequency | Monthly |

| Key Maintenance Tasks | Lens cleaning, mirror alignment, and belt checking |

| Common Materials to Engrave | Wood, acrylic, glass, and leather |

| Software Used | Inkscape, LightBurn, or AutoCAD |

| Safety Practice | Always have a fire extinguisher nearby |

| Design Tips | Use vector graphics for best results |

Related Posts

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Discover the Power of Laser Tables in Modern Precision Engineering and Design

-

How to Optimize Laser Machining for Precision and Efficiency

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025