Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

In the rapidly evolving landscape of manufacturing technology, stainless steel laser cutting stands out as a pivotal area of innovation. As we look ahead to 2025, several groundbreaking advancements are anticipated that will transform how this process is executed, enhancing efficiency, precision, and capabilities across various industries. The emergence of new laser technologies, advanced automation systems, and cutting-edge software solutions are set to redefine the standards of stainless steel laser cutting, enabling manufacturers to produce intricate designs with unmatched accuracy.

This article explores the top ten innovations in stainless steel laser cutting that are expected to make a significant impact in the near future. By examining these advancements, we can gain insight into how they will not only streamline production processes but also improve environmental sustainability and reduce operational costs. As companies seek to maintain competitive advantages in an increasingly complex market, staying informed about these trends will be crucial for stakeholders involved in manufacturing, engineering, and design. Join us as we delve into the future of stainless steel laser cutting and what to watch for in the coming years.

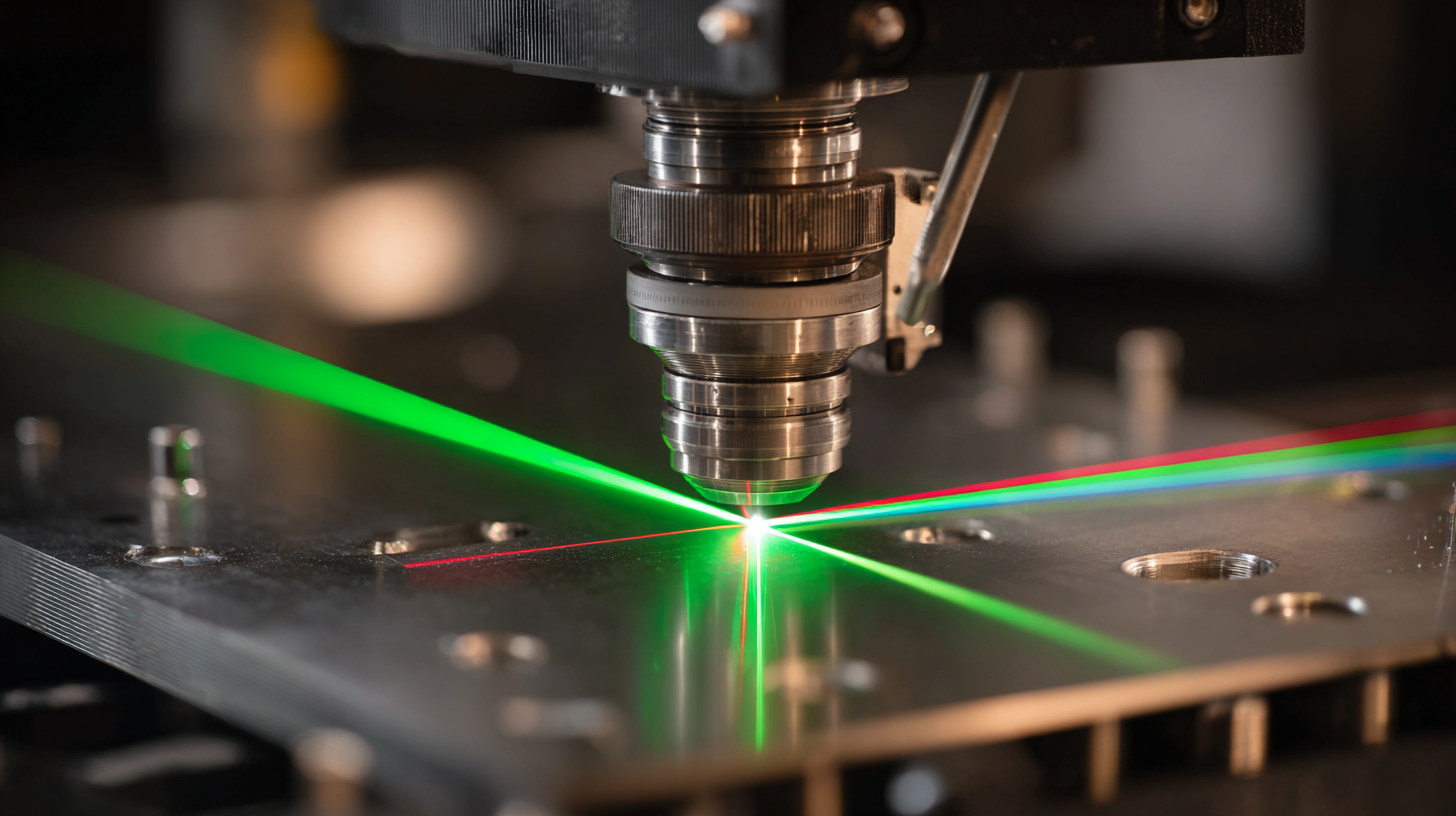

Advancements in High-Power Laser Technology for Stainless Steel Cutting

The landscape of stainless steel laser cutting is rapidly evolving, largely due to advancements in high-power laser technology. In 2025, we expect to see significant enhancements in the efficiency and precision of laser cutting processes. New technologies, such as fiber lasers and disk lasers, are capable of producing higher power outputs while maintaining energy efficiency. This innovation not only streamlines production but also allows for more intricate designs and thicker materials to be cut cleanly and precisely.

As these advancements unfold, it's essential to stay informed about best practices for utilizing high-power lasers effectively.

Tip: Always ensure that your laser cutting equipment is well-maintained to achieve optimal performance. Regular inspections can prevent downtime and enhance cut quality. Additionally, consider investing in advanced software that can optimize cutting paths, reducing waste and improving speed.

The integration of automation and artificial intelligence in laser cutting systems is another game-changer on the horizon. These technologies can predict maintenance needs and troubleshoot issues in real-time.

Tip: Embrace training opportunities for your team to adapt to these emerging technologies. A skilled workforce is vital to harnessing the full potential of innovative cutting methods, ensuring seamless integration into existing workflows.

Integration of AI and Machine Learning in Laser Cutting Processes

The integration of AI and machine learning into laser cutting technologies marks a significant frontier in manufacturing innovation. Forecasts indicate that the global laser cutting market will exceed $6 billion by 2025, with AI deployment expected to enhance operational efficiency by up to 30%. Recent collaborations, such as the partnership between leading laser system manufacturers and AI chip developers, are paving the way for smart laser systems capable of real-time optimization. These systems can adapt cutting parameters based on material behavior, enabling an unprecedented level of precision and reducing waste.

Moreover, startups in this sector are leveraging machine learning algorithms to improve predictive maintenance in laser cutting equipment. According to a recent industry analysis, companies employing AI-driven approaches have reported a 25% decrease in downtime due to preemptive maintenance alerts. As the landscape evolves, recognizing these trends and the impact of emerging startups will be essential for businesses aiming to enhance productivity and remain competitive. Embracing these innovations not only streamlines manufacturing processes but also positions companies at the forefront of both technology and market evolution.

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025 - Integration of AI and Machine Learning in Laser Cutting Processes

| Innovation | Description | Expected Impact | Year of Implementation |

|---|---|---|---|

| Automated Path Optimization | AI algorithms calculate the most efficient cutting paths for stainless steel. | Increased cutting speed and reduced material waste. | 2025 |

| Predictive Maintenance | Machine learning models predict maintenance needs before failures occur. | Reduced downtime and increased machine lifespan. | 2025 |

| Real-time Quality Control | AI systems monitor cutting quality in real-time and make adjustments. | Higher quality products and reduced rework. | 2025 |

| Enhanced Software Interfaces | AI-driven user interfaces for easier machine operation. | Improved usability and reduced training time. | 2025 |

| Smart Material Recognition | AI systems automatically identify materials and adjust settings accordingly. | Increased precision and consistency across different materials. | 2025 |

| AI-driven Energy Efficiency | Optimization of energy usage during the cutting process via AI. | Lower energy costs and reduced environmental footprint. | 2025 |

| Integrated Workflow Automation | Full automation of the laser cutting workflow with AI. | Increased throughput and decreased labor costs. | 2025 |

| Data-Driven Decision Making | Utilization of data analytics for informed decision-making in production. | Improved operational efficiency and reduction in waste. | 2025 |

| Advanced Simulation Techniques | Simulation of laser cutting processes using AI for design validation. | Faster prototyping and reduced design flaws. | 2025 |

Emerging Materials for Enhanced Laser Cutting Efficiency in 2025

In the realm of stainless steel laser cutting, emerging materials are set to redefine efficiency and precision by 2025. As reported by the International Laser Cutting Association, the integration of advanced materials such as high-performance ceramics and composites can significantly enhance the speed and quality of laser cutting processes. These materials not only withstand higher temperatures but also reduce wear on laser cutting equipment, extending their lifespan and minimizing operational costs.

Furthermore, innovative coatings designed for stainless steel are expected to improve laser interaction by optimizing reflectivity and energy absorption. According to a study by the Metal Forming Association, such advancements could lead to efficiency gains of up to 30%, allowing for faster production times without compromising on the integrity of the cut. As the demand for precision-engineered components grows, leveraging these emerging materials will be crucial in meeting the industry’s evolving standards and enhancing productivity in laser cutting technologies.

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

Innovative Software Solutions for Precision and Efficiency in Stainless Steel Cutting

The landscape of stainless steel laser cutting is evolving rapidly, driven by innovative software solutions that enhance precision and efficiency. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $6.5 billion by 2025, with a significant contribution from advancements in software applications. These innovations streamline the cutting process, allowing manufacturers to reduce waste and improve output quality, which is essential in a competitive market.

One of the noteworthy trends is the integration of artificial intelligence and machine learning in laser cutting software. These technologies optimize cutting paths in real time, adjusting parameters based on material type and thickness to achieve the best results. A recent study published in the Journal of Manufacturing Processes highlighted that leveraging such intelligent systems can increase cutting speeds by up to 30%, while also lowering operational costs. As manufacturers seek to enhance their capabilities, these innovative software solutions will undoubtedly play a pivotal role in shaping the future of stainless steel laser cutting.

Environmental Sustainability Trends in Laser Cutting Technologies for Stainless Steel

As the world increasingly prioritizes environmental sustainability, laser cutting technologies for stainless steel are evolving to meet these demands. Innovations in laser cutting are expected to play a significant role in reducing waste and improving efficiency within the industry. According to a market research report, the stainless steel sheet market is anticipated to surpass USD 180.4 billion by 2032, reflecting a compound annual growth rate (CAGR) of over 6.1% from 2025. This growth shows the rising demand for environmentally friendly manufacturing processes, where laser cutting offers precision without the excess material loss associated with traditional methods.

In addition, the Global Hand Tools Market is projected to reach USD 43.96 billion by 2034 at a CAGR of 4.5%. This rise is indicative of a broader trend towards innovative tool solutions that emphasize sustainability. Companies are now focusing on integrating advanced laser technologies into hand tools, enhancing their performance while minimizing their environmental footprint.

Tip: When considering advancements in laser cutting technologies, look for systems that employ fiber lasers, which are noted for their energy efficiency and lower operational costs. Furthermore, it’s beneficial to keep an eye on industry leaders and their developments, as they often pave the way for sustainable innovations.

Related Posts

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

What is the Advantage of Using a CNC Router for Your Business

-

Top Laser Machining Trends for 2025: Innovations and Applications You Can't Miss

-

Exploring Laser Machining Innovations at China Import and Export Fair 2025

-

Exploring the Art of Precision Crafting with CNC Engravers in Modern Design Projects