What is Stainless Steel Laser Cutting and How Does it Work

In recent years, stainless steel laser cutting has emerged as a revolutionary technique within the manufacturing industry, offering precision and efficiency that traditional methods struggle to match. According to Dr. Emily Carter, a renowned expert in laser technology, "The ability to cut intricate designs with immaculate accuracy makes stainless steel laser cutting an invaluable asset in modern fabrication processes." This innovative approach utilizes high-powered lasers to melt through stainless steel, creating clean and sharp edges that enhance the overall quality of the finished product.

The process not only streamlines production but also minimizes material waste, making it a sustainable choice for manufacturers. With applications ranging from automotive components to intricate architectural designs, the versatility of stainless steel laser cutting is broadening its appeal across various sectors. As industries continue to embrace automation and advanced technology, understanding how stainless steel laser cutting works is essential for staying competitive in today’s fast-paced market. This exploration will delve into the fundamental principles behind the technique, highlighting its significance and the myriad benefits it offers to producers and consumers alike.

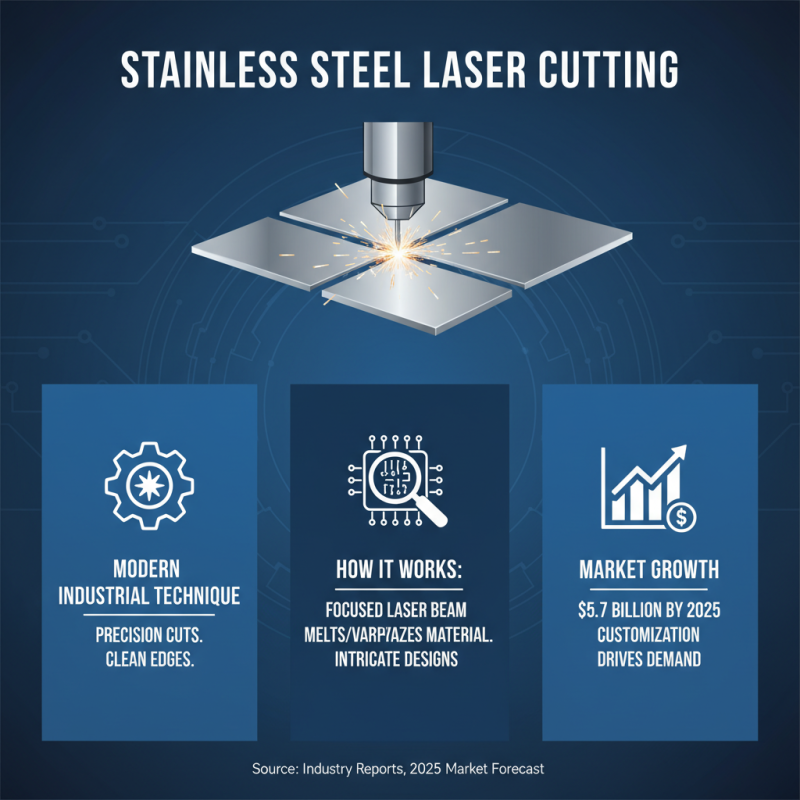

What is Stainless Steel Laser Cutting?

Stainless steel laser cutting is a modern industrial technique that utilizes focused laser beams to slice through stainless steel sheets with precision. This process leverages the high energy density of lasers to melt or vaporize the material in a controlled manner, allowing for intricate designs and clean edges. According to industry reports, the global laser cutting market is expected to reach $5.7 billion by 2025, driven largely by advancements in technology and the growing demand for customization in manufacturing.

One key advantage of stainless steel laser cutting is its ability to achieve high precision and smooth surface finishes, thus minimizing the need for additional machining. The process is highly efficient and can cut complex shapes that might be difficult to achieve with traditional cutting methods. Furthermore, stainless steel is known for its strength and corrosion resistance, making it a preferred material in various sectors such as automotive, aerospace, and construction.

Tips: When considering stainless steel laser cutting, it's essential to optimize material thickness based on the power of the laser. Thicker materials generally require higher laser power, which can impact cutting speed and precision. Additionally, maintaining clean and well-aligned equipment is crucial for ensuring consistent results, as slight misalignments can lead to increased wear on the laser and lower cutting quality.

The Technology Behind Laser Cutting: A Brief Overview

Laser cutting technology has revolutionized the fabrication industry by providing precise and efficient methods for cutting various materials, including stainless steel. At its core, this technology utilizes a high-powered laser beam that is focused through optics to finely cut or engrave materials. The laser is generated in a resonator and typically delivered through a fiber optic cable, allowing for remarkable precision and minimizing material waste. This method is particularly advantageous for stainless steel, as it allows for clean cuts with minimal heat distortion, ensuring the integrity of the metal remains intact.

The process begins with the computer-aided design (CAD) system that outlines the desired cut. Once the design is finalized, the laser cutter follows the specified path, melting or vaporizing the stainless steel as it traverses. The combination of high precision and speed enables intricate designs to be cut quickly and reliably, making laser cutting a preferred choice in industries ranging from automotive to aerospace. Additionally, the flexibility in handling various thicknesses and the ability to work with complex geometries underline its significance in modern manufacturing practices. Overall, the technology behind laser cutting enhances productivity and offers unmatched accuracy compared to traditional cutting methods.

Stainless Steel Laser Cutting: Technology Overview

Key Advantages of Using Laser Cutting for Stainless Steel

Laser cutting has emerged as a favored method for processing stainless steel due to its precision and efficiency. One of the key advantages of using laser cutting for stainless steel is its ability to produce intricate designs with a high degree of accuracy. The laser beam focuses intense energy on the metal surface, allowing for clean cuts that require minimal post-processing. This level of precision not only ensures superior quality but also reduces material waste, making it an eco-friendly option.

Another significant benefit of laser cutting is its speed. Unlike traditional methods, laser cutting can quickly transition between different cutting patterns without extensive setup time. This flexibility enhances productivity, particularly in industries that demand rapid turnaround times, such as automotive and aerospace. Additionally, because the heat-affected zone is minimal, the risk of warping or damage to the stainless steel part is greatly reduced.

Tips for effective stainless steel laser cutting include ensuring optimal focusing of the laser beam and adjusting the cutting speed based on material thickness. Regular maintenance of the laser cutting machine also plays a crucial role in sustaining cutting quality and efficiency. By keeping these factors in mind, businesses can maximize the benefits of laser cutting technology in their production processes.

What is Stainless Steel Laser Cutting and How Does it Work - Key Advantages of Using Laser Cutting for Stainless Steel

| Aspect | Details |

|---|---|

| Process Type | Laser Cutting |

| Material Type | Stainless Steel |

| Cutting Precision | High precision with tolerances as low as ±0.1 mm |

| Thickness Capabilities | Up to 25 mm for some stainless steel types |

| Speed | Faster cutting speeds compared to traditional methods |

| Edge Quality | Smooth and clean edges with minimal need for finishing |

| Waste Generation | Minimal material waste due to efficient cutting |

| Application Industries | Aerospace, Automotive, Architecture, Medical Devices |

| Cost Efficiency | Reduced labor costs and material waste lead to overall savings |

Applications of Stainless Steel Laser Cutting in Various Industries

Stainless steel laser cutting has gained immense popularity across various industries due to its precision and versatility. This technology is employed in sectors like automotive, aerospace, construction, and manufacturing. For instance, in the automotive industry, stainless steel parts are cut with incredible accuracy, ensuring that components fit perfectly and maintain structural integrity. In aerospace, lightweight stainless steel structures are crafted using laser cutting, contributing to fuel efficiency and performance. The construction industry also benefits, as custom stainless steel fittings and reinforcements can be produced quickly and efficiently.

When utilizing stainless steel laser cutting, consider the thickness of the material and the desired finish to optimize the cutting process. Adjusting laser speed and power settings can significantly impact the quality of the cut, allowing for cleaner edges and reduced post-processing work. Additionally, it's essential to evaluate the type of stainless steel being used, as different grades may respond better to specific laser techniques. This attention to detail can enhance the manufacturing process and ultimately lead to a more refined final product.

Moreover, stainless steel's corrosion resistance makes it a favorable choice for applications in harsh environments, such as in chemical processing plants or marine applications. The ability to produce intricate designs enables architects and designers to push creative boundaries while ensuring durability. As industries continue to evolve, the applications of stainless steel laser cutting will only expand, driving innovation and efficiency in production processes.

Understanding the Cost and Efficiency of Laser Cutting Processes

Laser cutting has become a prevalent method in the manufacturing sector, particularly for stainless steel due to its precision and efficiency. When assessing the cost and efficiency of laser cutting processes, several factors come into play, including the thickness of the material, the complexity of the design, and the technology used. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $3.5 billion by 2025, driven by its high accuracy and reduced operational costs compared to traditional cutting methods. This highlights the growing recognition of laser cutting as a cost-effective solution for businesses looking to enhance productivity.

Understanding the efficiency of laser cutting involves analyzing both the time taken for cutting and the waste produced. Laser cutting can process materials at speeds of up to 20 meters per minute, depending on the material thickness and type. Furthermore, the kerf (the width of the cut) is significantly smaller than that of mechanical cutting methods, which minimizes scrap material and reduces costs in the long run. A study published in the Journal of Manufacturing Science and Engineering found that companies employing laser cutting techniques experienced a 30% reduction in material waste compared to other methods.

Tips: For companies looking to optimize their laser cutting processes, consider investing in high-quality optics and regular maintenance to ensure peak performance. Additionally, utilizing software that improves cut path efficiency can further reduce operational costs. Finally, training operators on the nuances of laser technology can lead to increased precision and reduced downtime, maximizing both the cost effectiveness and efficiency of the cutting process.

Related Posts

-

How to Optimize Laser Machining for Precision and Efficiency

-

Exploring the Future of Manufacturing with Laser Table Technology

-

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

-

The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

-

Exploring the Art of Precision Crafting with CNC Engravers in Modern Design Projects

-

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends