What is Stainless Steel Engraving and How is it Done?

Stainless steel engraving is a fascinating process in the manufacturing industry. It combines artistry and precision. According to a recent market report, the global stainless steel engraving market is projected to reach $5 billion by 2026, growing at a CAGR of 5.2%. This growth reflects the rising demand for personalized and durable products.

Expert John Smith, a leading figure in stainless steel engraving, emphasizes its significance: "Engraving on stainless steel not only enhances aesthetics but also improves durability." This technique is vital for industries ranging from jewelry to industrial applications. The effectiveness of stainless steel engraving lies in its ability to withstand harsh environments while providing a lasting impression.

However, challenges exist within the industry. Many engraving techniques can be costly and time-consuming. Achieving the perfect finish requires a balance of technology and skill. Mistakes can lead to wasted material and increased expenses. Finding that balance is not always straightforward, which invites ongoing discussions about innovation in the field. As the industry evolves, the quest for perfection and efficiency continues.

What is Stainless Steel Engraving?

Stainless steel engraving is a process that involves etching or cutting designs into stainless steel surfaces. This technique is popular in various industries, including manufacturing and art. It allows for permanent designs that can withstand harsh environments. The durability of stainless steel makes it an ideal medium for both industrial applications and decorative items.

Engraving can be done using various methods. One common technique includes laser engraving, which provides precision and detail. Another method is chemical etching, where a solution removes the metal to create designs. Each method has its pros and cons. For instance, laser engraving requires careful setup but delivers high precision. Chemical etching can be less precise, leading to potential imperfections.

Engraving stainless steel can present challenges. The hardness of the material may lead to tool wear, requiring frequent replacements. Additionally, achieving consistent depth can be difficult. Mistakes can also occur, such as being off-center or misaligned. Every error can lead to additional work, necessitating patience and skill. As artists and manufacturers navigate these hurdles, the results can be rewarding and visually striking.

What is Stainless Steel Engraving and How is it Done?

| Engraving Method | Description | Applications | Advantages |

|---|---|---|---|

| Laser Engraving | Uses a laser beam to remove material and create designs. | Jewelry, awards, industrial parts. | Precision, versatility, no material degradation. |

| Chemical Etching | Involves applying a chemical solution to engraved areas of stainless steel. | Nameplates, decorative motifs, industrial components. | Smooth finish, detail, and complex designs. |

| Mechanical Engraving | Uses a rotary cutter to carve designs into stainless steel. | Manufacturing parts, corporate logos. | High durability and tactile quality. |

| Electrolytic Engraving | Uses electric current to remove metal in the shape of a stencil. | Personalized items, technical components. | Clean edges, suitable for intricate designs. |

History and Evolution of Stainless Steel Engraving Techniques

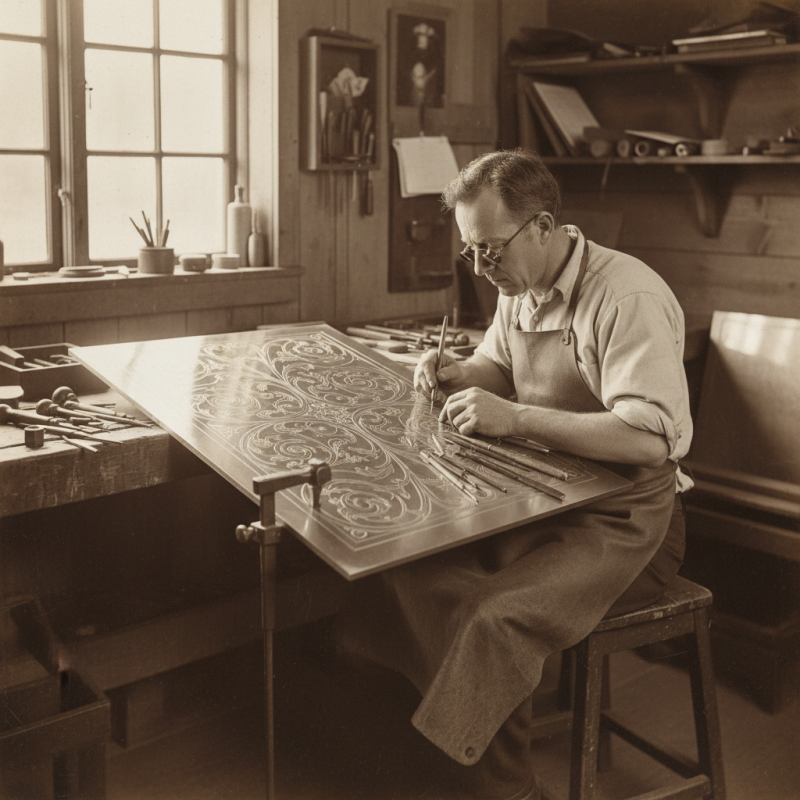

Historically, stainless steel engraving has evolved significantly. It began with simple hand tools in the 19th century. Craftsmen etched designs manually, which often took days. This method was labor-intensive but allowed for unique creations. As technology advanced, so did the techniques.

In the mid-20th century, engraving machines emerged. These devices enhanced precision and speed. However, some craftsmen resisted the change. They cherished the personal touch of hand engraving. This tension between tradition and innovation continues today.

Tip: When considering engraving techniques, think about your desired design. Some designs lend themselves well to machines, while others require a human touch. Choosing the right method affects the final outcome. Engraving in stainless steel is also about experimenting. Mistakes can lead to unexpected beauty.

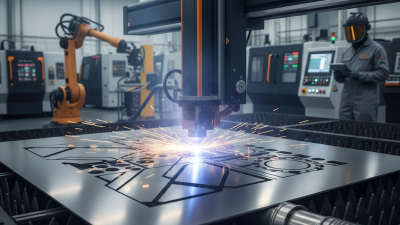

The digital age introduced laser engraving. It revolutionized the industry. Yet, some argue this lacks soul. Each method has its strengths and weaknesses. Reflecting on these can help you choose the right approach for your project.

Common Methods of Engraving on Stainless Steel

Engraving on stainless steel is a popular technique used across various industries. There are several common methods of engraving. Laser engraving is one of the most prevalent. It uses a focused beam of light to etch designs into the metal. This method is highly precise, with tolerances as small as 0.01 mm. It is often favored for intricate designs.

Another widely used technique is mechanical engraving. This involves using tools to remove material from the surface. The depth can be adjusted, allowing for various effects. Reports indicate that mechanical engraving can achieve depths of up to 2 mm. However, this method can be time-consuming and requires skilled operators.

Chemical etching is also noteworthy. This technique involves applying a chemical solution to create designs. It is particularly efficient for producing large quantities of uniform engravings. It can be less forgiving than other methods, resulting in some inconsistencies if not monitored closely. Each technique has its strengths and weaknesses. It is essential to choose the right engraving method based on the project's requirements and constraints.

Tools and Equipment Required for Stainless Steel Engraving

Stainless steel engraving requires specific tools and equipment for precision and quality results. One of the primary tools is an engraving machine, which can be manual or CNC-controlled. Manual engravers are great for small jobs, while CNC machines offer more detailed outcomes. You will also need engraving bits that are compatible with stainless steel. These bits come in various shapes and sizes to create different effects.

Additionally, safety gear is crucial when engraving stainless steel. Protective eyewear should always be worn to shield your eyes from metal shards. Noise-canceling headphones can be beneficial, particularly when working in a noisy environment. A steady work surface reduces vibrations, which enhances precision.

Tips: Always test your tools on a scrap piece of stainless steel first. This helps avoid mistakes on your final project. Don’t rush the engraving process; take your time to ensure accuracy. Measure multiple times before engraving. Mistakes can lead to costly errors. Properly maintained tools last longer and perform better.

Applications and Benefits of Stainless Steel Engraving

Stainless steel engraving is a versatile technique with numerous applications. It allows for the creation of detailed designs on surfaces that are tough and resistant to corrosion. Common uses include personalization of items like jewelry, awards, and tools. The precision of the engraving process ensures that even intricate patterns can be accurately reproduced.

The benefits of stainless steel engraving are substantial. It provides a durable finish that withstands wear and tear. This durability makes engraved items ideal for both decorative and functional purposes. Additionally, stainless steel's resistance to rust and staining ensures that the engravings remain vibrant over time. This durability often leads to cost savings in the long run. However, achieving perfect results can be challenging, requiring skilled technicians and appropriate equipment. Mistakes can occur, leading to designs that may not meet expectations, prompting a reevaluation of techniques used.

Furthermore, stainless steel engraving can offer emotional value. Personalized items can hold sentimental significance, making them treasured gifts. Despite its advantages, engraving can be limited by the material itself. Not every design can be flawlessly executed, and the surface finish must often be prioritized. Finding that balance is a continuous journey for many artisans in the field.

Related Posts

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025

-

What is Stainless Steel Laser Cutting and How Does it Work

-

What is the Advantage of Using a CNC Router for Your Business

-

How to Optimize Laser Machining for Precision and Efficiency

-

What is Laser Cutting Service and How it Revolutionizes Modern Manufacturing

-

How to Set Up Router Tables for Perfect Woodworking Projects