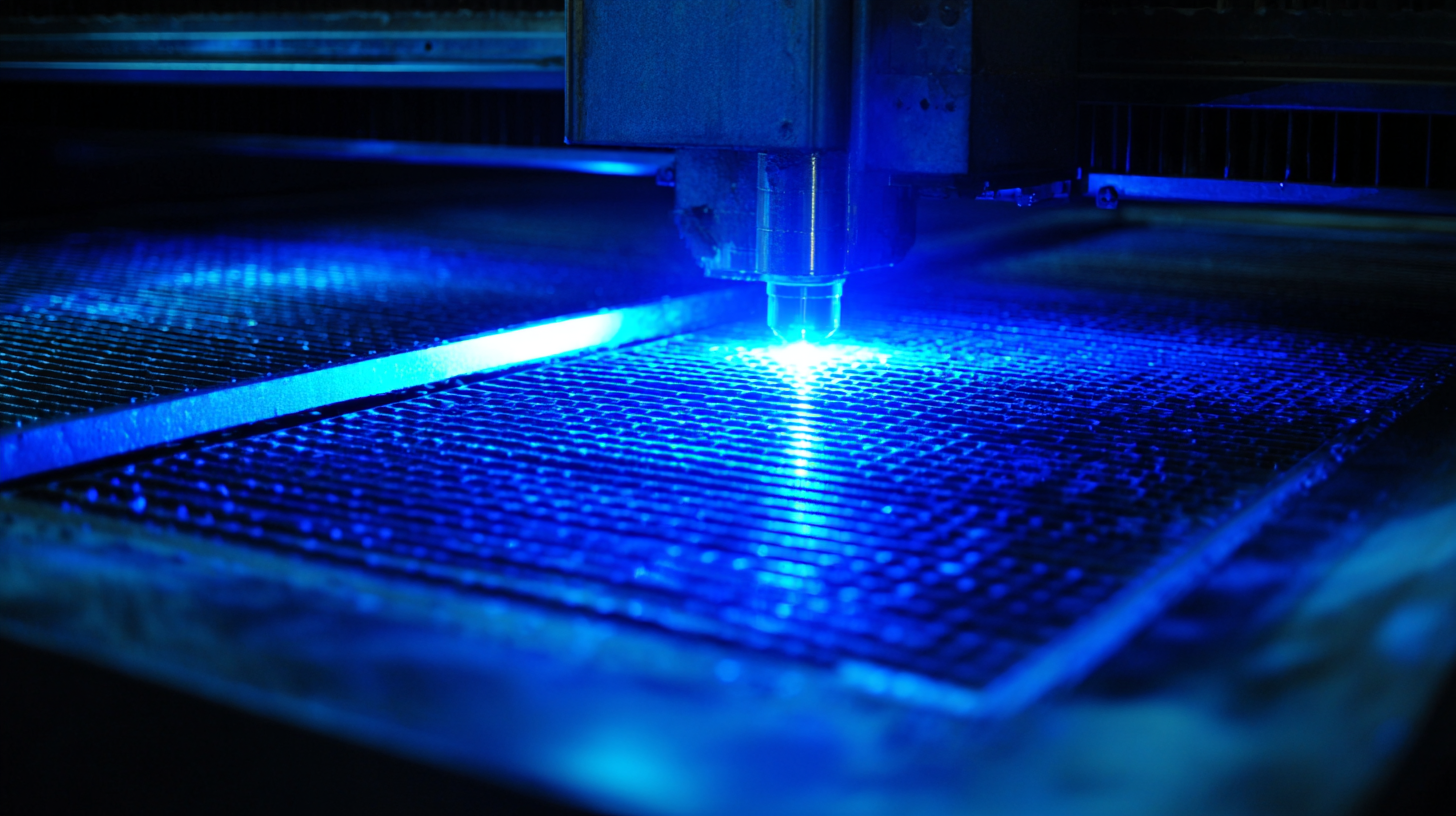

Discover the Power of Laser Tables in Modern Precision Engineering and Design

In the realm of modern precision engineering and design, the integration of advanced technologies has revolutionized traditional methodologies, with laser tables emerging as a pivotal tool. According to a recent industry report by MarketsandMarkets, the global laser cutting machine market is projected to reach USD 6.9 billion by 2025, driven by the increasing demand for high-precision manufacturing across various sectors. Laser tables, characterized by their ability to provide precise cuts and engravings with minimal material waste, are essential in enhancing both efficiency and accuracy in production processes. This technology not only accelerates workflow but also significantly reduces operational costs, making it indispensable for engineers and designers looking to innovate. As industries continue to embrace the digital transformation, the versatility and precision of laser tables will undoubtedly play a crucial role in shaping the future of engineering design.

The Evolution of Laser Tables in Precision Engineering

The evolution of laser tables in precision engineering has significantly transformed the way industries approach design and manufacturing. Initially, laser technology was primarily used for cutting applications, but advancements have expanded its role to include engraving, marking, and even additive manufacturing processes. According to a report by MarketsandMarkets, the global laser processing market is projected to reach $12.96 billion by 2026, highlighting the increasing reliance on laser-based technologies in various industrial applications.

One of the most remarkable advancements in laser tables is their integration with computer numerical control (CNC) systems, which has enhanced accuracy and efficiency. The latest systems feature advanced optics and high-powered lasers that can achieve tolerances of up to ±0.01 mm, significantly reducing material waste and production time. A report from Allied Market Research states that the demand for advanced laser cutting systems is expected to grow at a CAGR of 6.8% from 2020 to 2027, driven by industries seeking precision in complex parts manufacturing.

Furthermore, laser tables are now equipped with sophisticated software that allows for real-time adjustments and monitoring. This adaptability not only increases the versatility of the machines but also empowers engineers to innovate designs that were previously considered unfeasible. As companies continue to invest in modern laser table technology, the landscape of precision engineering and design will undoubtedly advance, fostering new possibilities and efficiencies in production lines.

Innovative Applications of Laser Tables in Design Processes

Laser tables have revolutionized the landscape of modern precision engineering and design, offering innovative applications that enhance creativity and accuracy. In various design processes, these advanced tools enable engineers and designers to manipulate materials with unparalleled precision. For instance, laser cutting technology allows for intricate designs in metal, wood, and plastic, making it easier to produce complex geometries that were previously difficult or impossible to achieve. This capability not only reduces material waste but also significantly shortens production times, enabling a faster transition from concept to prototype.

Moreover, laser tables facilitate real-time adjustments during the design phase. The integration of computer software with laser cutting technology allows designers to visualize changes instantly, testing various configurations without the need for extensive physical prototyping. This adaptability fosters a more dynamic creative process, as teams can experiment freely and refine their designs on-the-go. The application of laser tables in design processes exemplifies how technology can bridge the gap between imagination and realization, empowering professionals to push the boundaries of what is possible in their respective fields.

Comparative Advantages of Laser Tables Over Traditional Machining Techniques

The advent of laser tables in precision engineering signals a revolutionary shift from traditional machining techniques, offering significant advantages in terms of accuracy and efficiency. Laser processing technology enables remarkable surface quality, particularly in advanced materials like superalloys. For instance, recent studies reveal that waterjet-guided laser processing of DD6 superalloys, which are crucial for turbine rotor blades, achieves superior surface finishes with higher material yield compared to conventional methods. This is critical in aerospace applications where component integrity and performance are paramount.

Additionally, sustainable practices are becoming increasingly important in various industries, including leather production. A comparative analysis of ultrasonic and laser-assisted machining demonstrates that laser technology not only reduces waste and environmental impact but also enhances cutting precision. Reports indicate that implementing laser cutting techniques can lead to a reduction of up to 30% in resource consumption. As industries strive to meet both precision and environmental standards, the shift towards laser tables represents a forward-thinking approach that combines technological advancement with sustainable practices, making it an indispensable asset in modern engineering and design.

Future Trends in Laser Table Technology for Enhanced Precision

As precision engineering evolves, laser tables are becoming increasingly vital in enhancing design accuracy. The future trends in laser table technology are set to revolutionize industries by integrating advanced features such as automated calibration, enhanced software interfaces, and real-time data analytics. These innovations will enable designers and engineers to achieve unprecedented levels of precision, reducing human error and increasing efficiency in production processes.

Tips: To maximize the benefits of laser tables, ensure regular maintenance and calibration. This will maintain their accuracy and extend their lifespan. Additionally, staying updated with the latest software can provide insights and functionalities that significantly enhance design capabilities.

Moreover, the incorporation of AI in laser table operations is on the rise. By utilizing machine learning algorithms, these systems can adapt and optimize performance based on previous tasks, leading to smarter and faster production lines. This convergence of AI and laser technology promises not only to improve precision but also to foster new design possibilities that were previously unattainable.

Tips: Consider attending workshops or training sessions that focus on the latest laser table technologies. This hands-on experience can provide valuable knowledge on leveraging these tools for maximum impact in your projects.

Challenges and Solutions in Implementing Laser Tables in Engineering

The integration of laser tables in modern precision engineering and design presents significant challenges that require strategic solutions to ensure optimal performance. A report by Research and Markets indicates that the laser cutting market is projected to grow from $4.2 billion in 2021 to $6.3 billion by 2026, highlighting the increasing reliance on laser technologies across various industries. However, the implementation of laser tables can encounter issues such as high initial costs, the need for extensive training, and compatibility with existing machinery.

To address these challenges, companies must invest in comprehensive training programs for engineers and operators. According to a study published in the Journal of Manufacturing Processes, organizations that prioritize workforce development see productivity increases of up to 30%. Furthermore, collaboration with manufacturers of laser systems for tailored solutions can significantly enhance compatibility and reduce downtime, which is crucial in high-stakes environments like aerospace and automotive engineering, where precision is paramount. Leveraging innovative software that integrates well with laser tables can also streamline workflows and mitigate integration hurdles, leading to smoother implementation processes.

Related Posts

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Maximizing Your Workspace Efficiency with the Right Cutting Table for Your Crafting Needs

-

Unlocking the Future of Manufacturing Through Laser Machining Innovations and Trends

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects