How to Optimize Laser Machining for Precision and Efficiency

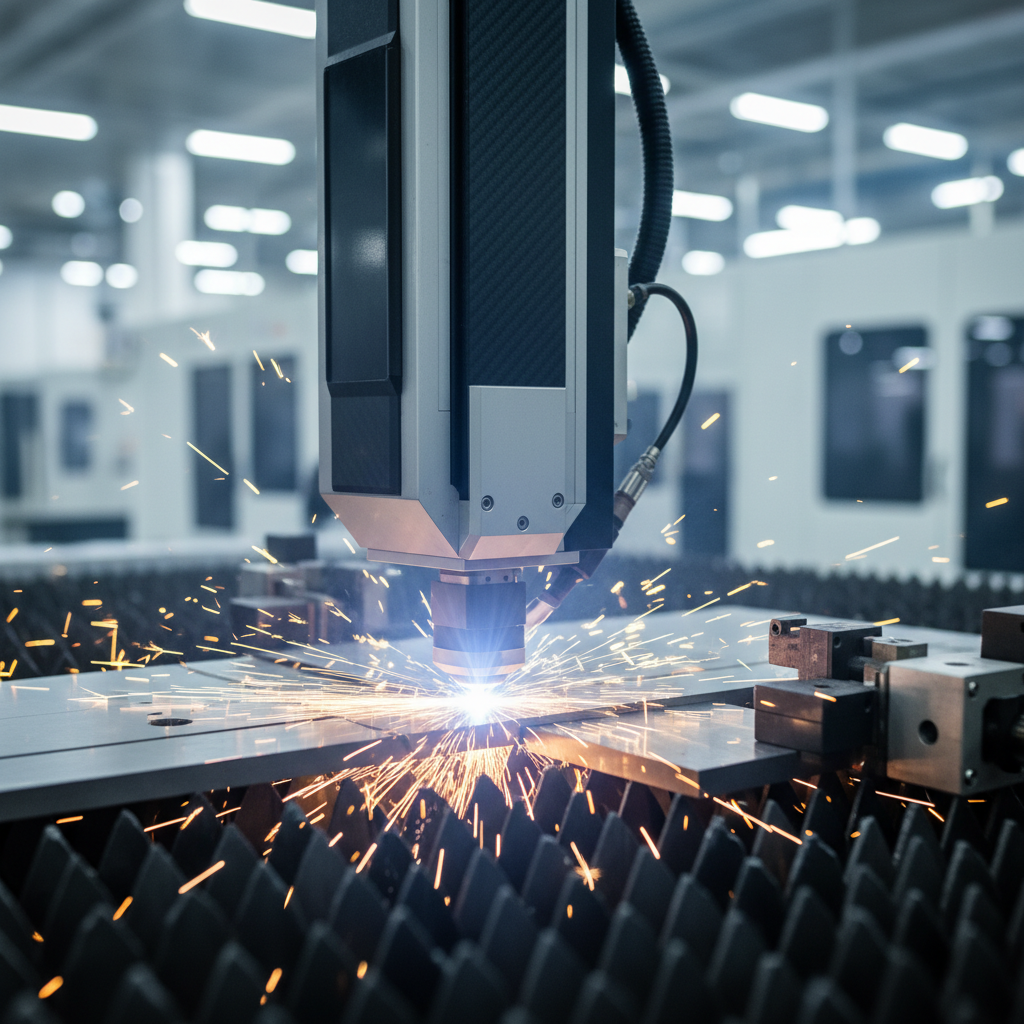

In the rapidly evolving landscape of manufacturing, laser machining has emerged as a cornerstone technology, offering unparalleled precision and efficiency in material processing. As industries strive to enhance productivity while maintaining high-quality standards, optimizing laser machining becomes crucial. This article delves into effective strategies to refine laser machining processes, ensuring that organizations can achieve both precision and operational efficiency.

By exploring cutting-edge techniques and advancements in laser technology, we aim to provide valuable insights into how manufacturers can harness the full potential of laser machining. Topics such as laser parameters, material selection, and process optimization will be examined, revealing how fine-tuning these elements can lead to significant improvements in output quality and cost-effectiveness.

Ultimately, the goal is to equip readers with the knowledge necessary to excel in the competitive landscape of modern manufacturing, leveraging laser machining as a key driver of innovation and success.

Identifying Key Factors Affecting Laser Machining Precision

Laser machining is a highly precise manufacturing process, and several key factors significantly affect its precision. One of the primary factors is the quality of the laser beam itself. A high-quality beam with a consistent focus can greatly enhance cutting accuracy, reducing kerf width and improving edge quality. Additionally, the wavelength of the laser plays a critical role; different materials respond uniquely to various wavelengths, so selecting the appropriate laser type for the specific material being machined is essential for achieving optimal results.

Another vital aspect is the machinery's operational parameters, such as speed, power, and pulse duration. Adjusting these parameters can lead to improved precision by minimizing thermal distortion and maximizing material removal efficiency. Moreover, the setup of the workpiece and its alignment with the laser path can influence the machining outcome. A well-secured and properly aligned workpiece minimizes vibrations, leading to a cleaner cut and enhanced dimensional accuracy. By focusing on these key factors, manufacturers can optimize laser machining processes for superior precision and operational efficiency.

Innovative Technologies Enhancing Laser Efficiency in Manufacturing

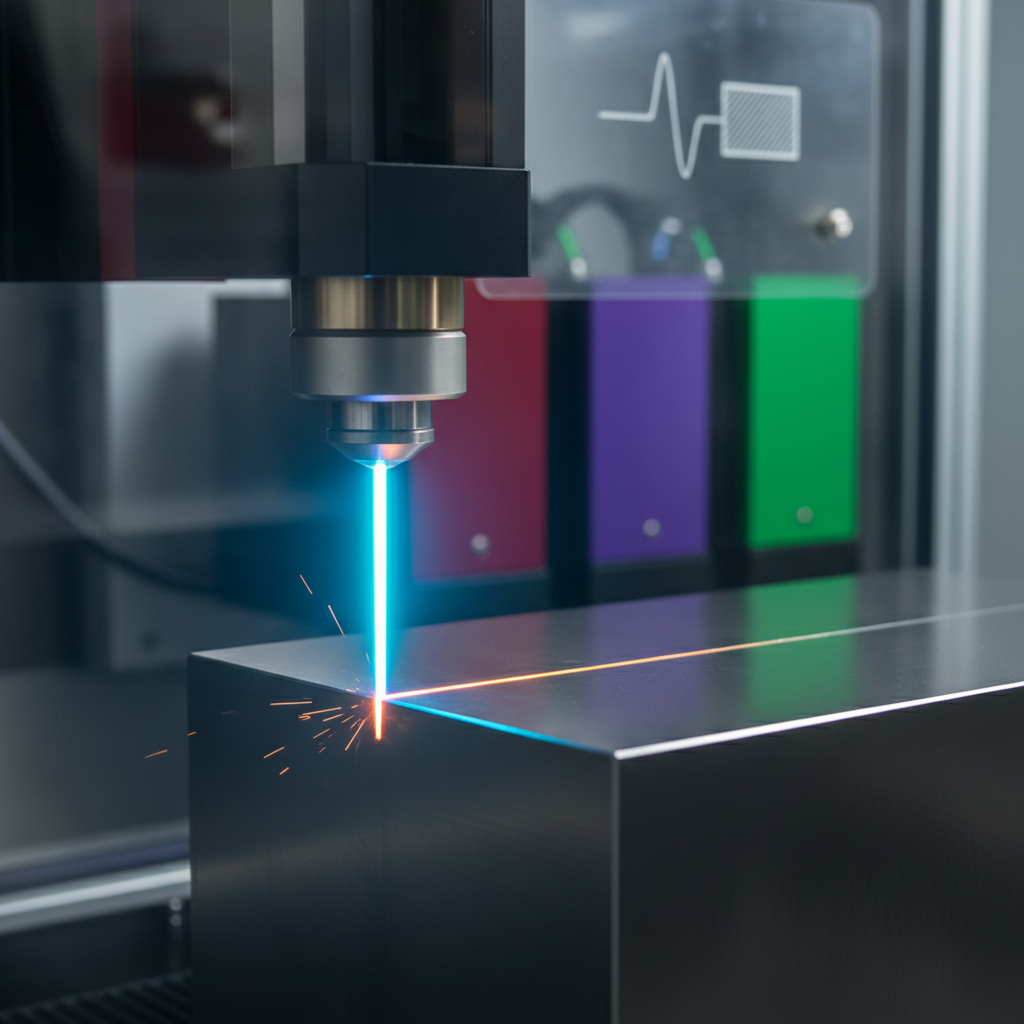

The field of laser machining is evolving rapidly, driven by innovative technologies that enhance efficiency and precision in manufacturing. Recent trends highlight the integration of AI and machine learning to streamline processes, allowing for real-time adjustments and improved quality control. Additionally, advancements in fiber laser technology are enabling manufacturers to achieve sharper cuts with minimal waste, thus elevating operational efficiency.

Tips for optimizing your laser machining processes include investing in automation tools that can monitor performance metrics and adjust settings accordingly. Implementing advanced software solutions that utilize predictive analytics can also significantly reduce downtime and enhance productivity. Another trend worth noting is the collaboration with startups focusing on laser technology innovations; these partnerships can provide fresh insights and cutting-edge solutions tailored to your specific needs.

In the realm of additive manufacturing, organizations like NUWC Keyport are pioneering cost-saving innovations through advanced laser techniques. These innovations not only reduce material waste but also shorten lead times, making them essential for businesses looking to stay competitive. Adopting these innovative practices can transform your manufacturing processes, ultimately promoting a culture of efficiency and precision.

Best Practices for Maintaining Consistent Laser Beam Quality

Maintaining consistent laser beam quality is crucial for optimizing laser machining, as it directly impacts both precision and efficiency.

One of the best practices in ensuring high beam quality is regular calibration of the laser system. This involves checking alignment and focal position to maintain optimal performance.

Any misalignment can lead to variations in beam diameter and intensity, which can compromise the accuracy of the machining process.

Routine inspections help identify and rectify any issues early, thereby preventing costly downtimes.

Another significant aspect is the control of ambient conditions in the working environment.

Factors such as temperature, humidity, and dust can affect laser performance and beam quality. Implementing a clean and temperature-controlled workspace helps in minimizing disruptions that could alter the behavior of the laser beam.

Furthermore, utilizing high-quality optics and lenses ensures that the beam remains focused and delivers consistent energy to the workpiece. By adhering to these best practices, manufacturers can achieve more reliable results in laser machining, enhancing both precision and efficiency throughout the production cycle.

Integrating Automation for Streamlined Laser Machining Processes

Integrating automation into laser machining processes is a game-changer for achieving precision and efficiency. By leveraging advanced automated systems, manufacturers can reduce operational downtime and improve throughput. Automated laser machining enhances accuracy by minimizing human error, providing consistent results across multiple production runs. This automation not only streamlines workflow but also enables real-time monitoring and adjustments, ensuring optimal performance throughout the machining process.

Tips for Integration:

- Invest in robust software solutions that facilitate seamless communication between CNC machines and automation tools. This integration is key to achieving a cohesive production environment.

- Regularly train staff on operating automated systems. Empowering your team with the right knowledge enhances productivity and minimizes disruptions during production.

- Consider implementing predictive maintenance schedules for automated machinery to foresee potential issues before they escalate into costly downtimes.

By focusing on these strategies, manufacturers can optimize their laser machining processes, ultimately leading to greater efficiency and higher quality outcomes.

Evaluating Performance Metrics for Optimal Laser Machining Outcomes

Evaluating performance metrics is crucial for achieving optimal outcomes in laser machining. According to the Laser Institute of America, precision in laser cutting can improve the overall yield by up to 25%, significantly reducing material waste. Key performance indicators (KPIs) such as cutting speed, kerf width, and heat-affected zone (HAZ) must be meticulously analyzed to ensure that the machining process not only meets quality standards but also operates efficiently. For instance, a recent study published in the Journal of Manufacturing Processes highlighted that optimizing the pulse duration and frequency settings could enhance cutting speed by 30% without compromising edge quality.

Furthermore, various metrics such as uptime, turnaround time, and energy consumption should be continuously monitored. Data from a 2022 report by the International Society of Automation indicates that integrating real-time analytics can lead to a 15% increase in operational efficiency in laser machining setups. By harnessing advanced data analytics and machine learning techniques, manufacturers can identify bottlenecks in their processes and adapt quickly, ensuring that both efficiency and precision are achieved in tandem.

Laser Machining Performance Metrics

Related Posts

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Exploring Laser Machining Innovations at China Import and Export Fair 2025

-

Top Laser Machining Trends for 2025: Innovations and Applications You Can't Miss

-

Top 10 Laser Cutting Tables for Precision and Efficiency in 2023

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects