Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends

In today's manufacturing landscape, personalization has emerged as a vital component in creating products that resonate with consumers. Among the various methods employed to achieve this level of customization, metal engraving stands out as an essential technique. As industries evolve, the demand for unique and individualized items continues to rise, making metal engraving a key player in meeting these consumer expectations. This article will explore how metal engraving not only enhances product uniqueness but also reflects broader industry trends towards personalized manufacturing.

With advancements in technology and shifts in consumer behavior, businesses are increasingly recognizing the importance of differentiation. Metal engraving allows manufacturers to imprint specific designs, names, or messages onto products, transforming ordinary items into cherished possessions. This capability is not just about aesthetics; it represents a deeper connection between the product and the user. As we delve into the significance of metal engraving, we will uncover its role in driving customer loyalty and its impact on the overall manufacturing process in 2025 and beyond. Embracing this personalization trend through metal engraving can be a game-changer in an increasingly competitive marketplace.

The Role of Metal Engraving in Custom Product Design

Metal engraving has emerged as a pivotal element in custom product design, reflecting the growing consumer demand for personalization in manufactured goods. According to a recent report by Market Research Future, the global personalization market is expected to reach $40 billion by 2027, underlining the significant role of customized products in attracting consumer attention. Metal engraving allows for intricate designs, logos, and personal messages, making items not only functional but also meaningful. This capability to tailor products precisely to customers' preferences enhances brand loyalty and satisfaction.

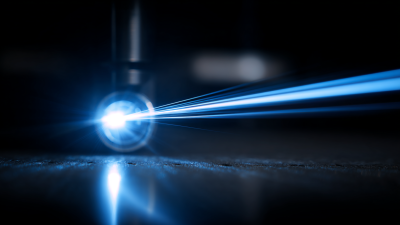

For manufacturers looking to capitalize on this trend, here are some tips: First, invest in high-quality engraving technology; precision matters. Laser engraving machines, for example, can produce detailed designs swiftly and efficiently. Second, engage with your customers to understand their personalization desires. Surveys or social media polls can be effective in gathering insights on design preferences. Lastly, create a portfolio showcasing examples of metal engraving on various products to inspire potential buyers and demonstrate versatility.

Incorporating metal engraving into product design is not just a trend; it is a transformative approach that aligns with the customization movement in manufacturing. With a strategic focus on consumer desires and advanced techniques, manufacturers can elevate their offerings and enhance customer experiences.

Emerging Trends in Personalized Manufacturing Solutions

The personalization of manufacturing solutions is increasingly becoming a focal point for industries seeking to differentiate their products in a crowded market. According to a report by McKinsey & Company, approximately 70% of consumers are willing to pay a premium for personalized products. This rising demand is driving manufacturers to adopt cutting-edge technologies that enable tailored solutions, particularly in metal engraving, which provides an effective way to customize items with precision.

Emerging trends reveal that companies are leveraging advanced metal engraving techniques not only for aesthetic appeal but also for functional differentiation. A study by Deloitte highlights that personalized manufacturing can lead to a 20% increase in customer satisfaction and loyalty. This is significantly important as businesses strive to enhance consumer experiences in a highly competitive landscape. Moreover, with the integration of automation and advanced software, metal engraving has become more accessible, allowing small and medium-sized enterprises to offer unique personalized products at scale—creating new opportunities for innovation and growth in the sector.

Trends in Personalization Solutions in Manufacturing

This chart illustrates the increasing significance of metal engraving as a personalized manufacturing solution from 2019 to 2023, highlighting the growing demand across various industries.

Advantages of Metal Engraving Over Other Personalization Methods

Metal engraving has emerged as a leading method for personalization in manufacturing, thanks to its durability and aesthetic appeal. Unlike other methods such as printing or stickers, which can fade or wear off over time, engraved designs offer a permanent solution that withstands the test of time. This process ensures that the personalization remains intact, making it a preferred choice for products that require longevity, such as jewelry, awards, and industrial parts.

Moreover, metal engraving provides a level of detail and precision that is hard to achieve with other techniques. The ability to create intricate designs and custom text elevates the uniqueness of each piece, catering to individual preferences. This precision ensures that the final product not only looks good but also aligns perfectly with customers' specifications, enhancing their overall satisfaction.

**Tips:** When considering metal engraving, think about the type of metal being used, as different materials can produce various finishes and results. Additionally, ensure you have a clear design idea before starting, as the engraving process is often irreversible. It’s also beneficial to partner with experienced engravers who can offer guidance on design choices and techniques that will bring your vision to life effectively.

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends

| Dimension | Metal Engraving | Other Personalization Methods |

|---|---|---|

| Durability | High | Moderate |

| Customization Scope | Wide array of designs | Limited in intricate details |

| Production Speed | Moderate | Fast |

| Cost-effectiveness | Higher initial setup but lower long-term costs | Lower initial, potentially higher ongoing costs |

| Environmental Impact | Low | Variable |

Case Studies: Successful Applications of Metal Engraving in Industries

In recent years,

metal engraving has emerged as a vital tool for personalization across various industries, showcasing its practical applications through several compelling case studies. For instance, in the luxury goods sector, companies like Rolex have integrated precise engraving techniques into their products to offer customized watch faces. This not only enhances the luxury appeal but also allows customers to engrave special dates or names, resulting in a unique product that fosters emotional connections between the consumer and the brand.

Similarly, in the automotive industry, manufacturers such as BMW have adopted metal engraving to personalize vehicles for their customers. This process allows buyers to add bespoke touches to their car interiors, such as engraved nameplates or unique design elements. These personalized aspects not only differentiate the vehicles in a competitive market but also elevate customer satisfaction by ensuring that each car reflects the owner's personality and preferences. This trend highlights how metal engraving not only serves functional purposes but also plays a critical role in building brand loyalty through personalized customer experiences.

Future Innovations in Metal Engraving Technology for Enhancing Personalization

Advancements in metal engraving technology are set to redefine personalization in manufacturing by enabling more intricate and customizable designs. One of the most exciting innovations on the horizon is the integration of artificial intelligence and machine learning. These technologies can assess consumer preferences and suggest personalized patterns, ensuring that each piece of metalwork resonates with its intended user. As companies adopt these smart systems, the time required for creative design will significantly diminish, allowing for rapid prototyping and production.

Moreover, the introduction of high-precision laser engraving methods is revolutionizing the quality of personalization. Contemporary lasers can achieve remarkable detail, allowing manufacturers to create intricate designs that were previously impossible. This not only enhances aesthetic appeal but also enables the inclusion of complex texts and images, making every engraved item unique to its owner. With these innovations, the future of personalization in metal engraving looks brighter than ever, promising a seamless blend of technology and creativity that meets the evolving demands of consumers.

Related Posts

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

What is the Advantage of Using a CNC Router for Your Business

-

Top Laser Machining Trends for 2025: Innovations and Applications You Can't Miss

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects