2025 How to Master Metal Engraving Techniques for Perfect Results

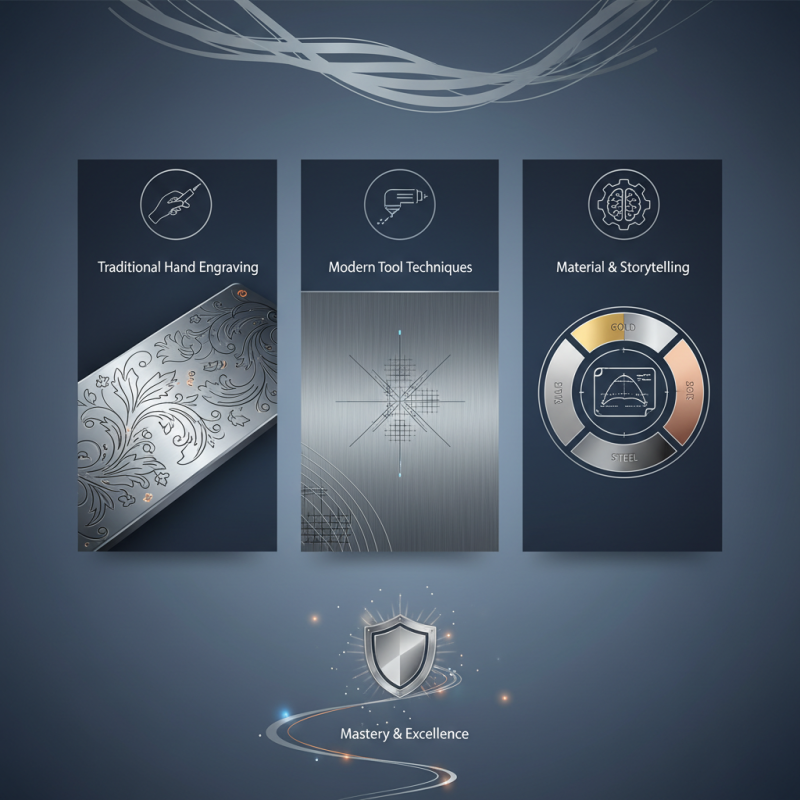

As the world of craftsmanship evolves, metal engraving remains a timeless skill that is appreciated across various industries. In recent years, artisans and creators have sought to refine their techniques, delivering impeccable results that showcase their dedication to the craft. According to renowned metal engraving expert, John H. Thompson, "Mastering metal engraving is not merely about technique; it’s about understanding the materials and the story each piece has to tell." This insight encapsulates the essence of succeeding in this art form, highlighting the balance between precision and creativity.

In the pursuit of perfect results, aspiring engravers are encouraged to hone their skills through practice and study. Various techniques, from hand engraving to the use of modern tools, can elevate one’s craftsmanship to new heights. The journey of mastering metal engraving invites artisans to explore the intricate relationships between design, functionality, and the metallic medium, which can transform ordinary surfaces into stunning illustrative pieces.

Understanding the fundamentals of metal engraving enables artists to push the boundaries of their creativity while ensuring that their work resonates with meaning and purpose. By delving into this comprehensive guide, readers will discover essential techniques, tips, and insights that can help them achieve excellence in their metal engraving projects and leave a lasting impression through their artistry.

Understanding the Basics of Metal Engraving Techniques

Understanding the fundamentals of metal engraving techniques is essential for achieving perfect results in this intricate craft. Metal engraving involves creating designs on a variety of metal surfaces using tools that can be manual or mechanical. According to a recent industry report published by the International Association of Engraving Professionals, the global market for metal engraving is expected to grow by over 5% annually, reflecting the increasing interest in custom metal works and personalized items. This growth emphasizes the need for both novice and seasoned engravers to master the foundational techniques that underpin this artistry.

At its core, mastering metal engraving begins with understanding the various tools and materials used. From traditional hand tools like burins and gravers to advanced laser engraving machines, each method offers unique advantages that can impact the final result. Studies indicate that using the correct engraving tool can reduce error rates by up to 30%, significantly improving the quality of the work. Additionally, familiarity with different metal types, such as aluminum, brass, and stainless steel, can influence the choice of technique; softer metals might require less force and detail than harder alloys. Engravers must practice on samples to discover the characteristics of each material and hone their skills for a more refined outcome.

2025 How to Master Metal Engraving Techniques for Perfect Results - Understanding the Basics of Metal Engraving Techniques

| Technique | Description | Skill Level | Recommended Tools |

|---|---|---|---|

| Laser Engraving | Utilizes a focused laser beam to engrave designs onto various metal surfaces. | Intermediate | Laser engraving machine, computer software |

| Hand Engraving | Uses manual tools to carve intricate designs into metal by hand. | Advanced | Graver, chasing hammer, magnifying lamp |

| Rotary Engraving | Involves rotating a cutting tool to engrave designs on metal surfaces. | Beginner | Rotary tool, various bits |

| Etching | Uses acid or other corrosive substances to cut into the surface of the metal. | Intermediate | Etching solution, resist materials |

| CNC Engraving | Computer Numerically Controlled machining for precise and automated engraving. | Advanced | CNC machine, CAD software |

Essential Tools and Materials for Metal Engraving

To master metal engraving techniques, it's crucial to have the right tools and materials at your disposal. First and foremost, a high-quality engraving tool is essential. Whether you choose a handheld engraver or a more advanced rotary tool, ensure it has adjustable speed settings to accommodate various engraving styles. Additionally, a set of different tip sizes will help you achieve intricate designs as well as bold lettering. Safety gear, such as goggles and gloves, will protect you from metal shavings and debris during the engraving process.

Apart from tools, the choice of materials significantly impacts your engraving results. Common metals for engraving include aluminum, brass, and stainless steel, each offering unique characteristics. Aluminum is lightweight and easy to engrave, making it a popular choice for beginners. Brass provides a classic look and is great for detailed work, while stainless steel, though more challenging to engrave, offers exceptional durability. It's also beneficial to have a secure work surface, like a vice or clamp, to stabilize your metal piece while you work. By selecting the right tools and materials, you can set yourself up for success in mastering metal engraving techniques.

Step-by-Step Guide to Different Engraving Methods

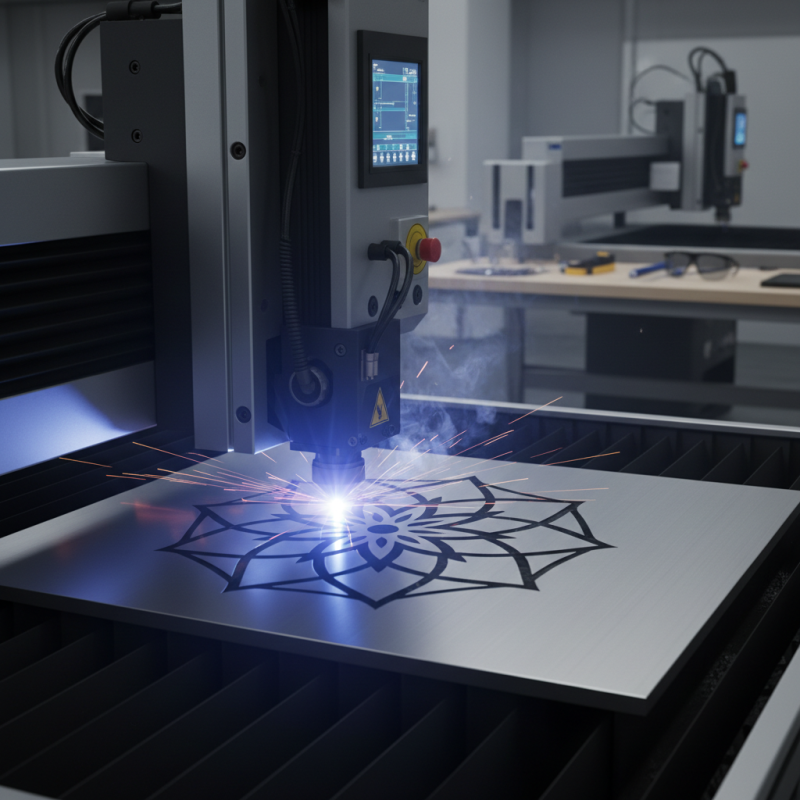

Mastering metal engraving techniques requires a deep understanding of various methods that can achieve perfect results. Among the most prominent techniques are laser engraving, rotary engraving, and chemical etching. According to a recent industry report from the Research and Markets, the global metal engraving market is projected to grow at a CAGR of 6.5% from 2023 to 2030. This growth highlights increasing demand for precision engraving in sectors like jewelry, automotive, and industrial applications.

Laser engraving stands out for its ability to produce intricate designs quickly and with precision, making it a favorite among artists and manufacturers alike. This method uses focused light beams to remove material and create designs, allowing for a depth of detail that is unmatched by traditional methods. Meanwhile, rotary engraving, which utilizes a rotating cutting tool, offers the advantage of being suited for a variety of materials and produces tactile surfaces, ideal for functional components. Research indicates that the shift towards personalized products is driving the adoption of rotary engraving techniques, especially in custom award and trophy production.

Chemical etching, although less common, provides an alternative that excels in producing fine lines and detailed imagery on metal surfaces. This method involves using corrosive chemicals to remove material, offering an efficient way to achieve complex patterns without the need for extensive machinery. As the market continues to evolve, mastering these techniques not only enhances creativity but also addresses the growing consumer demand for quality and personalization in metalwork.

Tips for Achieving Precision and Detail in Engravings

Achieving precision and detail in metal engraving requires a combination of skill, appropriate tools, and a deep understanding of the materials used. First and foremost, selecting the right engraving tools is crucial. High-quality burins or chisels, designed specifically for metal work, can significantly impact the clarity and accuracy of your engravings. Additionally, using a stable, well-lit workspace will help ensure that you can focus on the minute details of your project without unnecessary distractions.

Another key aspect to mastering metal engraving techniques is proper surface preparation. The metal surface should be clean and free of any contaminants to allow for smooth carving. Techniques such as sandblasting or polishing can enhance the texture of the metal, providing a better grip for your tools. Slow and deliberate movements during the engraving process allow for greater control, enabling you to produce intricate designs with precision. Utilizing a magnifying glass or a microscope can also aid in achieving finer details, especially in complex patterns or small lettering.

Lastly, practice is essential. Developing muscle memory through repetitive engraving on scrap metal will enhance your skill level over time. Experimenting with different techniques, such as V-cutting and shading, can also expand your capabilities and help you find your unique style. By focusing on these aspects—tools, surface preparation, and consistent practice—you can cultivate the precision and detail needed for perfect results in metal engraving.

Finishing and Protecting Your Engraved Metal Pieces

Finishing and protecting your engraved metal pieces is a crucial step in the metal engraving process, directly impacting both aesthetics and longevity. According to industry reports, approximately 75% of consumers express a preference for products that not only look good but are also durable. To achieve this, several finishing techniques can be employed. Techniques like polishing, anodizing, and powder coating not only enhance the visual appeal but also provide a protective barrier against corrosion and wear. For instance, anodizing aluminum can increase its resistance to scratches and environmental factors, prolonging the life of the engraved design significantly.

Moreover, applying sealants or protective coatings post-engraving further extends the lifespan of your work. A study in the Journal of Protective Coatings estimated that untreated metal surfaces can degrade by up to 30% faster in harsh environments compared to those that are appropriately finished and sealed. Utilizing UV-resistant clear coatings can safeguard against fading and discoloration, ensuring that the intricate details of your engraving remain vibrant over time. By integrating these finishing techniques and protective measures, metal engravers can deliver not only stunning but also enduring pieces that meet high consumer standards.

Related Posts

-

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends

-

Unlocking the Future of Manufacturing Through Laser Machining Innovations and Trends

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Discover the Power of Laser Tables in Modern Precision Engineering and Design

-

What is the Advantage of Using a CNC Router for Your Business

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive