How to Master CNC Cutting Techniques for Precision Manufacturing?

CNC cutting is revolutionizing the manufacturing landscape. As precision tools take the forefront, mastering these techniques becomes essential. Industry expert Dr. Emily Hu states, “Perfecting CNC cutting is not just about the machine; it’s about the skill behind the operator.” Her insight underscores the importance of comprehensive training and expertise in this field.

In CNC cutting, attention to detail is vital. Precision dictates project outcomes, making the understanding of software, tools, and materials crucial. Operators must learn the intricacies of their machines. Missteps can lead to significant waste. It’s not uncommon for even seasoned professionals to encounter challenges that question their methods. Reflection on these experiences can lead to valuable insights.

Continuous learning is necessary. The CNC cutting industry constantly evolves with new technologies and techniques. Staying updated can feel daunting, but it's essential for success. Mistakes should be viewed as opportunities for growth. Embracing the learning process will enhance skills and improve overall precision in manufacturing.

Understanding CNC Cutting: Definition and Applications in Precision Manufacturing

CNC cutting, or computer numerical control cutting, is crucial in precision manufacturing. This technology enables manufacturers to create intricate parts with high accuracy. CNC machines operate with computerized controls, making cuts based on precise measurements. According to a recent industry report, over 70% of manufacturers leverage CNC technology to improve part quality.

Applications of CNC cutting span various sectors. Aerospace, automotive, and medical industries rely on this method for producing components. For instance, CNC machines enhance the production of complex geometries in aerospace parts. This contributes to improved aerodynamics and fuel efficiency. However, not all CNC operations yield perfect results. Improper calibration can lead to dimensional errors, affecting overall quality.

Understanding the limitations of CNC cutting is essential. Machine wear and tear can compromise accuracy over time. Conversely, skilled operators are crucial for maintaining consistency. A lack of training may lead to operational inefficiencies. Investing in proper training and maintenance can address these challenges. As the industry evolves, embracing advancements will be vital for staying competitive.

Mastering CNC Cutting Techniques: Precision in Manufacturing

Types of CNC Cutting Techniques: An Overview of Methods and Tools Used

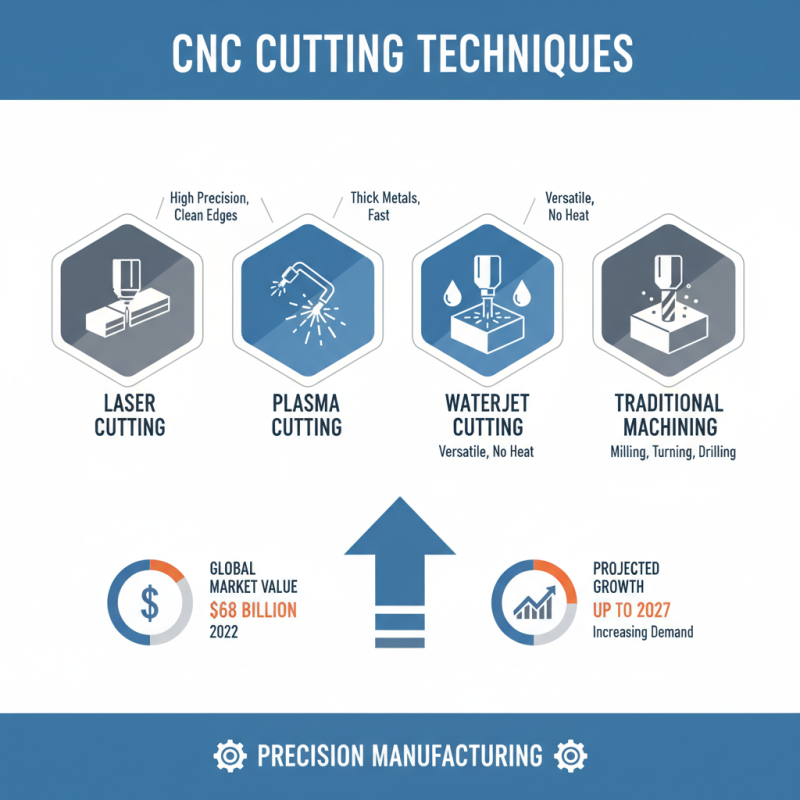

CNC cutting techniques are vital in precision manufacturing. Various methods are used, each with unique tools and characteristics. Common techniques include laser cutting, plasma cutting, waterjet cutting, and traditional machining. According to industry reports, the global CNC machining market size was valued at approximately $68 billion in 2022, with ongoing growth projected up to 2027. This growth highlights the increasing demand and the evolution of cutting methods.

Laser cutting is popular for its precision. It employs a high-powered laser to cut through materials like metal and plastic. The accuracy of laser cutting is within ±0.1 mm, making it ideal for intricate designs. In contrast, plasma cutting offers speed and efficiency, suitable for thicker materials, but may leave rough edges. Waterjet cutting is another excellent method. It uses high-pressure water to cut materials without heat, preserving their properties. However, it may require additional finishing processes.

Each technique has its challenges. For instance, the initial setup for laser cutting can be time-consuming. On the other hand, plasma cutting can produce fumes that require ventilation. Understanding these tools and their implications can enhance manufacturing processes. Continuous evaluation and adaptation of these techniques are essential for achieving desired precision and efficiency in production.

Key Parameters for CNC Cutting: Speed, Feed Rate, and Tool Selection

CNC cutting precision relies heavily on key parameters: speed, feed rate, and tool selection. According to industry reports, an optimal cutting speed can enhance efficiency. Typical speeds range between 100 to 1500 RPM, depending on the material. For instance, harder materials like titanium require slower speeds. This balance is crucial; too high might cause tool wear, while too low can lead to inefficient cuts.

Feed rate significantly impacts the cutting quality. Studies suggest a feed rate range of 0.01 to 0.5 inches per second. Setting the right feed rate can reduce the risk of chatter, which affects precision. However, choosing too aggressive a feed rate could result in poor finishes or tool breakage. Monitoring as you adjust feed rates helps in attaining that fine line between speed and quality.

Tool selection is another critical factor. The right tool geometry can drastically improve performance. A dull tool not only affects the finish but also increases part cycle time. Reports indicate that using the wrong tool can lead to 30% longer cutting times. It's vital always to assess tools after a few runs. Regular checks can prevent potential failures and enhance overall productivity. Fine-tuning these parameters requires constant adjustment and evaluation to achieve the desired precision in manufacturing.

How to Master CNC Cutting Techniques for Precision Manufacturing?

| Material | Cutting Speed (m/min) | Feed Rate (mm/min) | Tool Type |

|---|---|---|---|

| Aluminum | 150 | 600 | Carbide End Mill |

| Steel | 80 | 250 | High-Speed Steel (HSS) Tool |

| Plastic | 120 | 500 | Plastic Router Bit |

| Wood | 200 | 800 | Spiral Upcut Bit |

| Composite Materials | 90 | 300 | Diamond Coated Tool |

Material Properties and Their Impact on CNC Cutting Precision

Understanding material properties is crucial for achieving CNC cutting precision. Variations in hardness, density, and thermal conductivity directly influence the cutting process. For example, steel and aluminum behave differently under similar conditions. Steel, with its higher hardness, requires specific cutting speeds and tools to reduce wear. In 2023, recent industry studies indicate that approximately 30% of machining errors stem from inadequate material assessment.

Surface finish is another critical factor. Materials with rough surfaces can lead to tool wear or incorrect cuts. A study revealed that up to 25% of production waste is linked to poor surface preparation. Engineers must assess the material beforehand. This ensures they choose the right tools and settings. Additionally, thermal effects during cutting can cause expansion or distortion. Such variations can lead to tolerance issues.

Through proper understanding of these properties, manufacturers can minimize errors. Yet, many still overlook this area. Regular training on material characteristics can help. Failures in recognizing material behavior often translate into increased costs. Emphasizing quality checks during material selection can reduce these risks significantly.

Quality Control in CNC Cutting: Techniques for Ensuring Optimal Results

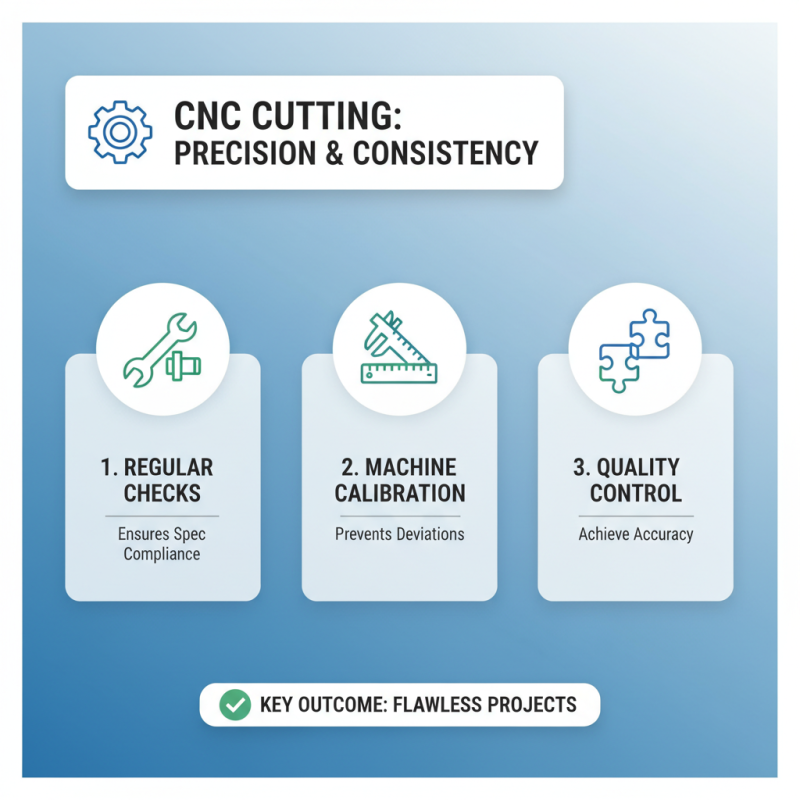

Quality control is crucial in CNC cutting to achieve precision and consistency. Implementing regular checks can help ensure that each cut meets the required specifications. Start by calibrating your machines frequently. Poorly calibrated tools can lead to significant deviations in dimensions. The difference might seem minor, but it can affect the entire project.

Visual inspections are also important. Use gauges and measuring tools to verify the dimensions of the cuts. It takes time, but identifying errors early can save resources later. Documenting every inspection creates a reliable reference. Still, relying solely on visual inspections isn't sufficient. Machines can malfunction unexpectedly, and raw materials may vary.

Finally, consider feedback from your team. They may notice patterns that aren’t visible in data alone. Encourage open communication about failures. Each mistake highlights areas for improvement. Embrace the learning process. Remember, perfection is the goal, but the journey is filled with challenges. Reflecting on these experiences can lead to better techniques and outcomes in CNC cutting.

Related Posts

-

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

-

Top 10 Laser Cutting Tables for Precision and Efficiency in 2023

-

How to Optimize Laser Machining for Precision and Efficiency

-

How to Set Up Router Tables for Perfect Woodworking Projects

-

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends

-

Unlocking the Future of Manufacturing Through Laser Machining Innovations and Trends