What is Laser Cutting Service and How it Revolutionizes Modern Manufacturing

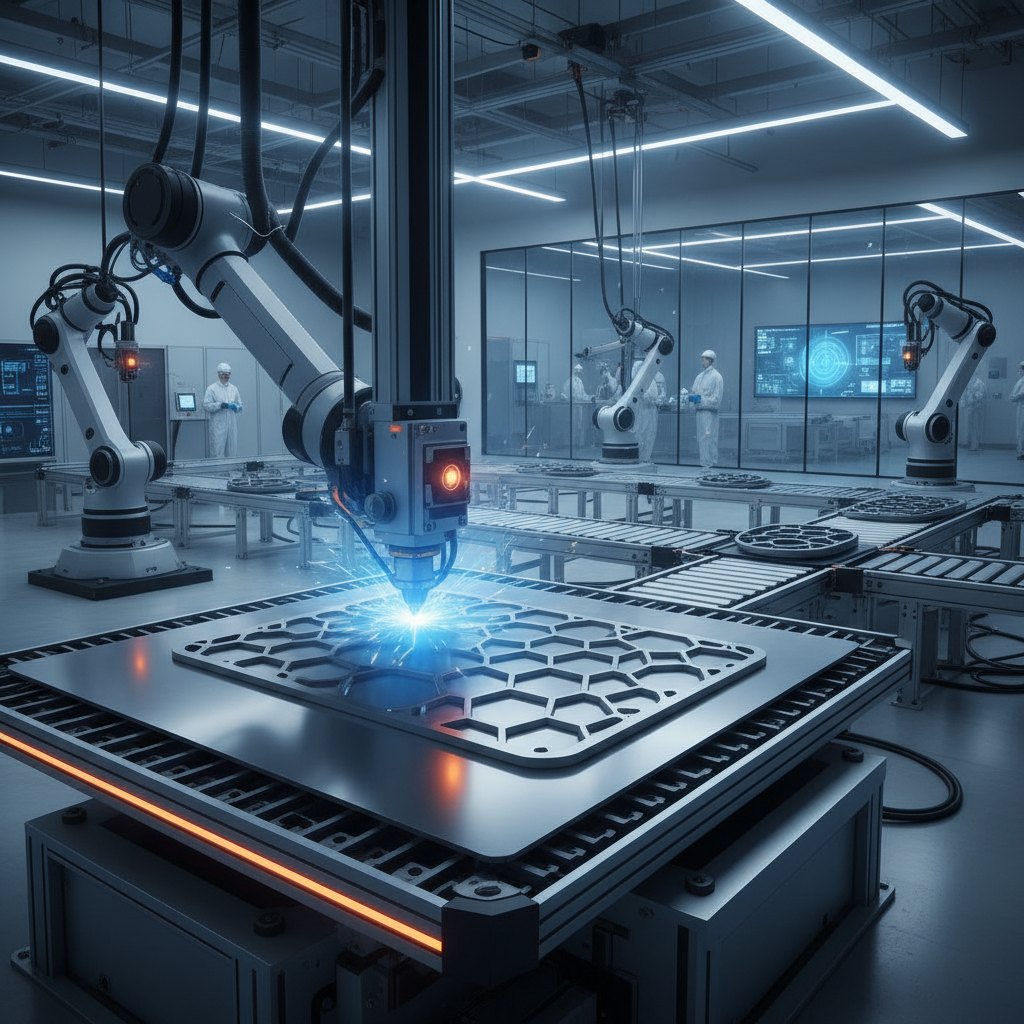

The advent of laser cutting service has marked a pivotal transformation in the landscape of modern manufacturing. As industries increasingly demand precision, versatility, and efficiency, laser cutting technology provides a sophisticated solution that meets these needs. According to a report by Markets and Markets, the global laser cutting market is projected to reach USD 5.48 billion by 2025, growing at a CAGR of 5.9%. This surge is driven by the rising adoption of advanced manufacturing techniques and the growing need for high-quality finished products across various sectors, including automotive, aviation, and electronics.

Laser cutting service stands out due to its ability to achieve intricate designs and cuts with minimal tolerance levels, streamlining production processes and reducing material waste. A study from Research and Markets notes that the demand for custom components manufactured using laser cutting has increased significantly, emphasizing its importance in enhancing the competitive edge of businesses. As manufacturers seek to improve operational efficiency and reduce lead times, the role of laser cutting services continues to expand, positioning this technology as a cornerstone of innovative manufacturing solutions in the 21st century.

Overview of Laser Cutting Technology and Its Principles

Laser cutting technology has become a pivotal innovation in modern manufacturing, characterized by its precision and versatility. This technique utilizes a focused laser beam to cut or engrave materials with exceptional accuracy. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach USD 6.3 billion by 2025, growing at a CAGR of 7.2%. This growth reflects the increasing adoption of laser cutting in various industries, including automotive, aerospace, and electronics, where precise cuts and intricate designs are essential.

Principally, laser cutting operates based on the principles of thermodynamics—converting electrical energy into thermal energy. The laser beam heats the material, causing it to melt or vaporize in the targeted area. Different types of lasers, such as CO2 and fiber lasers, cater to specific materials and thicknesses, enhancing the ability to work with a diverse range of substrates, from metals to plastics. A study conducted by the International Journal of Advanced Manufacturing Technology indicates that laser cutting can achieve tolerances as tight as ±0.01 mm, far exceeding traditional cutting methods. This remarkable precision not only reduces material waste but also minimizes the need for secondary operations, making it a cost-effective solution in the competitive landscape of modern manufacturing.

| Aspect | Description | Benefits |

|---|---|---|

| Technology | Utilizes focused laser beams to cut materials | High precision and minimal material waste |

| Materials | Suitable for metals, plastics, wood, and fabrics | Versatility in processing a variety of materials |

| Applications | Used in automotive, aerospace, and signage industries | Wide range of industry applications |

| Process Speed | Cuts are made rapidly with minimal downtime | Increased efficiency in production processes |

| Cost-Effectiveness | Lower operational costs due to reduced material waste | Improved profitability and competitive advantage |

| Quality | Produces clean edges and consistent cuts | Enhances product quality and aesthetic appeal |

Key Benefits of Laser Cutting Services in Manufacturing

Laser cutting services have become a transformative force in modern manufacturing, offering numerous advantages that enhance productivity and precision. One of the key benefits lies in its ability to cut through various materials with exceptional accuracy, allowing manufacturers to create intricate designs without compromising on quality. According to industry reports, the laser cutting machine market is projected to witness significant growth, with estimates indicating a market expansion driven by increasing demand for high-precision components across sectors like automotive and aerospace.

Moreover, the efficiency of laser cutting optimizes material usage, reducing wastage and lowering production costs. This technology enables faster processing times compared to traditional cutting methods, further streamlining manufacturing workflows. The growing acceptance of laser cutting in developing regions is evident, as the Middle East laser cladding market is forecasted to grow from USD 17.0 million in 2024 to USD 37.3 million by 2033, indicating a compound annual growth rate (CAGR) that reflects the rising trend of adopting advanced manufacturing techniques. These developments highlight the vital role of laser cutting services in revolutionizing the manufacturing landscape by delivering unmatched speed and precision.

Applications of Laser Cutting Across Various Industries

Laser cutting has emerged as a transformative technology in modern manufacturing, with applications spanning numerous industries. In the automotive sector, laser cutting is utilized for precision parts manufacturing, allowing for intricate designs and reduced weight without compromising strength. This precision reduces waste and enhances production efficiency, making it a preferred choice among manufacturers striving for excellence.

In the aerospace industry, laser cutting plays a crucial role in the fabrication of components that require exact tolerances and intricate geometries. This capability not only aids in reducing the overall manufacturing time but also improves safety through enhanced accuracy. Similarly, in the architecture and construction sectors, laser cutting is used to create detailed patterns and structures from materials like metal and wood, enabling unique designs that push the boundaries of traditional construction methods.

Healthcare also benefits significantly from laser cutting technology, particularly in the production of medical devices and implants that require high precision. This technology facilitates the manufacture of complex geometries that improve the fitting and functionality of medical solutions, ultimately leading to better patient outcomes. Across these various industries, laser cutting exemplifies innovation, enhancing productivity while ensuring the highest quality standards.

Comparative Analysis: Laser Cutting vs. Traditional Cutting Methods

Laser cutting has emerged as a game-changer in the manufacturing sector, offering precision and efficiency that traditional cutting methods often can't match. According to a report from MarketsandMarkets, the laser cutting market is expected to reach $5.7 billion by 2025, with a compound annual growth rate (CAGR) of 5.8%. This surge is largely attributed to the superior accuracy and speed of laser cutting, which can achieve tolerances as tight as ±0.1 mm, compared to the ±0.5 mm typically seen with mechanical cutting methods like sawing and shearing.

When comparing laser cutting to traditional methods, it's important to consider indicators such as setup time and material waste. Laser cutting minimizes setup time significantly, allowing for faster production cycles. Furthermore, due to its precision, it generates far less waste—typically around 10% compared to the up to 30% waste linked with traditional methods. This not only leads to cost savings but also aligns with sustainability goals in manufacturing.

Tips: If you're considering transitioning to laser cutting, evaluate your material types first, as it performs exceptionally well on metals, plastics, and composites. Additionally, invest in training your staff on the technology to maximize the benefits and ensure efficient workflow integration for optimal results.

Future Trends in Laser Cutting and Their Impact on Manufacturing Efficiency

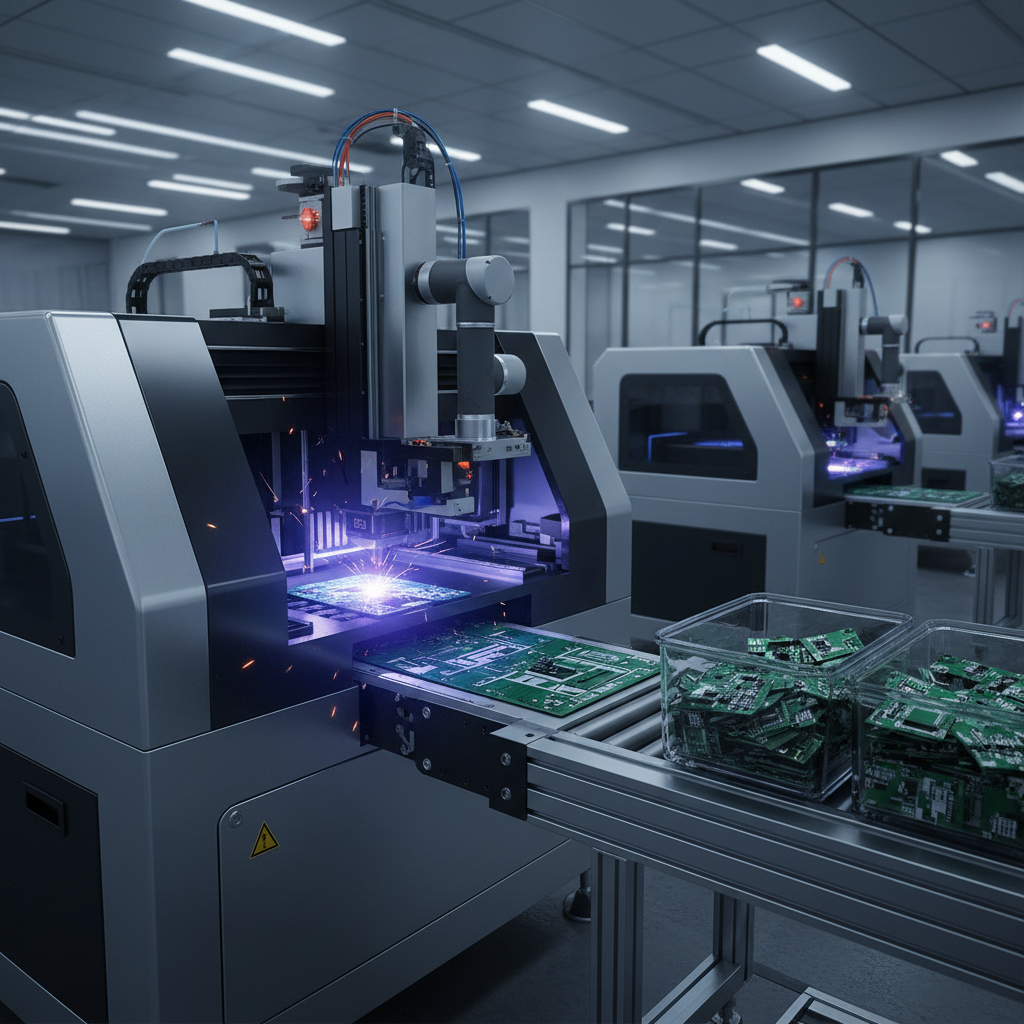

The future of laser cutting technology is set to transform manufacturing efficiency across various industries. One notable trend is the growing demand for off-line PCB laser depaneling systems, projected to reach a market value of $201.3 million by 2032, showing a steady growth rate of 4.7%. This shift towards automated solutions is indicative of a larger trend where precision and speed become paramount, allowing manufacturers to enhance production processes while reducing waste.

Additionally, the global laser lighting market is experiencing significant expansion, driven by applications in diverse sectors such as industrial and healthcare. By 2032, the market is expected to diversify further with a range of product types, including CO2 and fiber lasers. This diversification not only amplifies the capabilities of laser technologies but also increases efficiency in manufacturing practices, ultimately leading to higher productivity levels and better resource management. As companies continue to embrace these innovations, the efficiency of manufacturing processes is likely to improve, further solidifying laser cutting's role as a cornerstone of modern manufacturing advancements.

Related Posts

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking Creativity: How Laser Cutting and Engraving Transforms DIY Projects

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries