Top Laser CNC Trends to Watch in 2025 for Innovative Applications

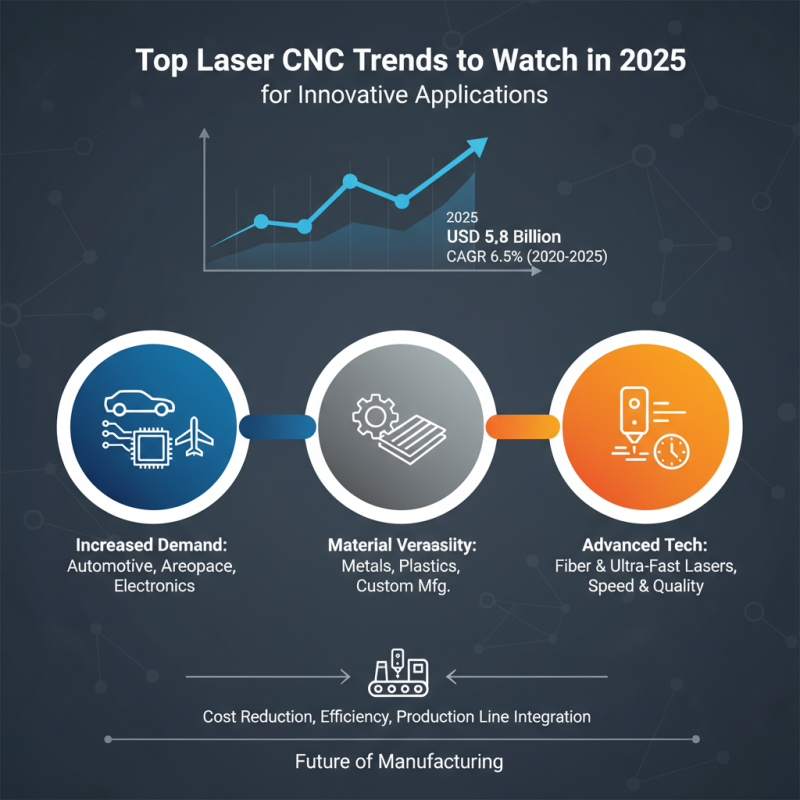

As we approach 2025, the landscape of manufacturing continues to evolve, with laser CNC technology at the forefront of innovation. According to a recent market research report, the global laser CNC market is projected to reach USD 5.8 billion by 2025, highlighting a compound annual growth rate (CAGR) of 6.5% from 2020. This growth is fueled by the increasing demand for precision cutting, engraving, and marking across various sectors, including automotive, aerospace, and electronics.

The versatility of laser CNC systems allows for the processing of a multitude of materials, ranging from metals to plastics, making them an ideal choice for custom manufacturing. Additionally, advancements in laser technology, such as fiber lasers and ultra-fast laser systems, are pushing the boundaries of what is possible, enabling innovative applications that enhance speed and quality. As industries seek to reduce costs and improve efficiency, the integration of laser CNC machinery into production lines is expected to surge, underscoring its pivotal role in the future of manufacturing. With these trends in mind, businesses must stay ahead by adopting the latest advancements in laser CNC technology to maintain a competitive edge in their respective markets.

Emerging Technologies in Laser CNC Machining for 2025

As we approach 2025, the laser CNC machining landscape is poised to undergo significant transformation due to the emergence of innovative technologies. According to a recent market analysis by MarketsandMarkets, the global laser machining market is expected to grow at a CAGR of 6.7% between 2020 and 2025, highlighting the increasing adoption of laser technology across various industries. Emerging technologies such as automation and artificial intelligence (AI) are becoming integral to optimizing laser CNC processes, enabling manufacturers to enhance precision, efficiency, and overall productivity.

One notable trend is the rising integration of AI-driven software with laser CNC systems, which facilitates real-time data analysis and machine learning capabilities. This advancement allows for predictive maintenance, thus reducing downtime and operational costs. Furthermore, sophisticated laser systems equipped with advanced beam shaping capabilities enable the machining of complex geometries with greater accuracy. A report by Research and Markets indicates that the adoption of fiber lasers in CNC machining is anticipated to rise significantly due to their superior energy efficiency and faster processing speeds. This shift towards more efficient laser applications is expected to revolutionize the manufacturing sector, offering innovative solutions that cater to the increasing demand for customization and shorter lead times in production.

Sustainability Innovations in Laser CNC Applications

As industries increasingly prioritize sustainability, the integration of eco-friendly practices in laser CNC applications is gaining momentum. According to a report by MarketsandMarkets, the global laser cutting market is projected to reach $5.8 billion by 2025, with a significant shift towards sustainable technologies. This trend is driven by the need to reduce waste and improve energy efficiency in manufacturing processes.

Innovative applications are emerging where laser CNC technology not only minimizes material usage but also enhances recyclability. For instance, advancements in laser cutting techniques allow for more precise cuts that reduce kerf loss, thereby conserving materials. Additionally, companies are investing in renewable energy sources to power laser CNC machines, further decreasing their carbon footprint. A study by the International Energy Agency highlights that integrating renewable energy could lower industrial emissions by up to 70%, emphasizing the role of laser CNC technologies in achieving environmental goals.

Furthermore, the development of biodegradable and sustainable materials compatible with laser CNC processes is on the rise, showcasing the potential for significant ecological advancement. The rise of smart manufacturing, coupled with laser CNC innovations, provides manufacturers with the ability to monitor and optimize resource consumption in real-time. As the demand for sustainable practices grows, laser CNC technology is well-positioned to play a pivotal role in the transition to greener manufacturing solutions.

Integration of AI and Machine Learning in Laser CNC Processes

The integration of artificial intelligence (AI) and machine learning (ML) in laser CNC processes is set to revolutionize the manufacturing landscape in 2025. By leveraging advanced algorithms, manufacturers can optimize cutting parameters, enhance precision, and reduce waste.

AI can analyze vast amounts of data generated during the cutting process, enabling real-time adjustments that improve the quality of output. This adaptive capability not only ensures consistent results but also accelerates production timelines, thereby increasing overall efficiency.

Moreover, the incorporation of machine learning allows laser CNC systems to learn from past operations. As these systems gather more data, they can identify patterns and predict potential issues before they arise. This predictive maintenance approach minimizes downtime and maintenance costs, which is particularly crucial in high-volume manufacturing environments. As industries continue to embrace automation, the synergy between AI, machine learning, and laser CNC technology will drive innovation, enabling the development of sophisticated applications that were previously unfeasible. This transformation will not only enhance productivity but also pave the way for customized solutions tailored to meet the unique demands of various sectors.

Advancements in Material Compatibility for Laser CNC Systems

The advancements in material compatibility for laser CNC systems are set to revolutionize the manufacturing landscape. As industries increasingly seek to optimize production processes and enhance design flexibility, the ability to work with a broader range of materials becomes crucial. In 2025, we can expect laser CNC machines to achieve higher precision and efficiency across various substrates, including metals, plastics, ceramics, and composites. This expanded compatibility allows manufacturers to streamline their operations by reducing the number of machines required for different materials, ultimately leading to cost savings and improved production timelines.

Additionally, the integration of sophisticated software will enable better material analysis and selection, facilitating the design of custom applications tailored to specific needs. With advancements in beam quality and laser power, these systems will cater to more demanding projects that require intricate details and high-quality finishes. As such, businesses can anticipate innovations in industries such as aerospace, automotive, and consumer goods, where the ability to manipulate diverse materials with laser CNC technology will significantly enhance product development and manufacturing processes. The year 2025 promises to be an exciting period for those engaged in laser CNC, with the potential to unlock creative solutions and push the boundaries of design capabilities.

Future Market Trends and Economic Impact of Laser CNC Technology

The future market trends for laser CNC technology are poised to create significant economic impacts across various industries. As precision manufacturing continues to evolve, laser CNC machines are expected to enhance efficiency and reduce operational costs. The integration of advanced automation and artificial intelligence with laser CNC systems will lead to more streamlined production processes, allowing businesses to respond more swiftly to market demands and customize products without increasing labor costs. This trend will be particularly noticeable in sectors such as automotive, aerospace, and consumer goods, where precision and rapid prototyping are critical.

Additionally, the economic implications extend beyond mere cost savings. The adoption of laser CNC technology promotes sustainability through reduced material waste and energy consumption. As manufacturers seek environmentally friendly practices, the growing emphasis on sustainable development will likely drive the demand for laser CNC systems that are energy-efficient and capable of utilizing recyclable materials. This shift not only helps in meeting regulatory standards but also appeals to consumers who are increasingly prioritizing sustainability, thus creating new market opportunities and fostering long-term economic growth for companies that embrace these innovations.

Related Posts

-

Top 10 Laser Cutting Tables for Precision and Efficiency in 2023

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023

-

How to Choose the Best Laser Table for Your Cutting Needs

-

Unlocking the Power of Laser Etching in Modern Manufacturing

-

Why Metal Engraving is Essential for Personalization in Manufacturing: Insights from Industry Trends