Exploring the Future of Manufacturing with Laser Table Technology

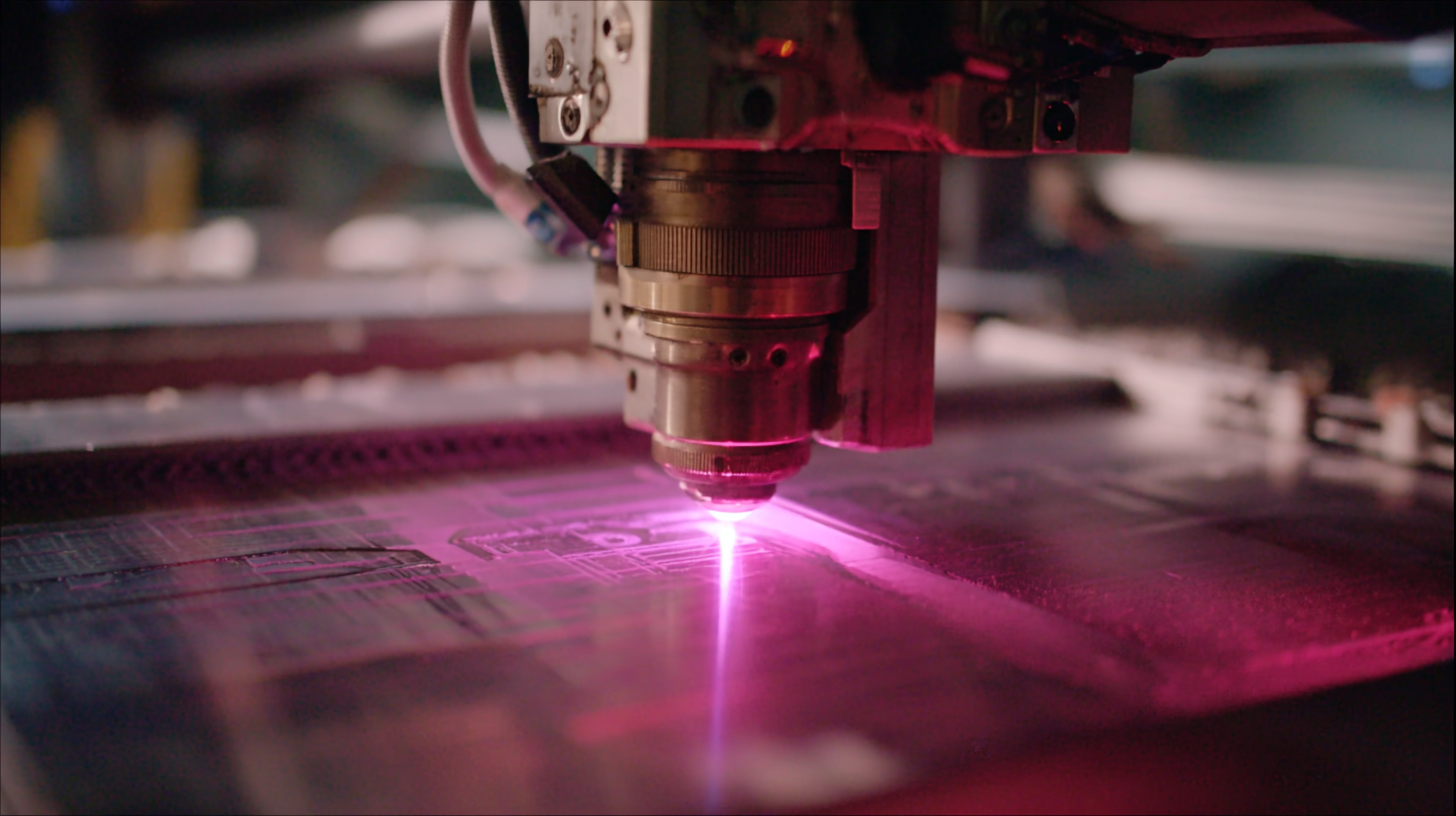

As we delve into the future of manufacturing, one technology stands out as a game changer: the laser table. This innovative tool is redefining production processes across various industries by enhancing precision, efficiency, and versatility. With its capability to cut, engrave, and mark materials with unparalleled accuracy, the laser table not only streamlines operations but also reduces material waste, resulting in cost savings. This exploration into the transformative potential of laser table technology will illuminate how manufacturers are adapting to the rapidly evolving landscape, leveraging advanced techniques to meet market demands while fostering sustainability.

By examining how laser tables integrate into traditional workflows and the advantages they bring to modern manufacturing, we can gain valuable insights into the future trajectory of this industry.

Impact of Laser Table Technology on Manufacturing Efficiency and Productivity Metrics

The rise of laser table technology is poised to revolutionize manufacturing efficiency and productivity metrics in unprecedented ways. By harnessing the precision and speed of laser cutting and engraving, manufacturers can significantly reduce material waste and enhance the overall workflow. This technological advancement allows for intricate designs to be produced quickly, minimizing downtime and maximizing output, ultimately leading to a more streamlined production process.

Tip: To fully leverage the benefits of laser table technology, consider investing in staff training focused on laser operations and maintenance. Well-trained operators can optimize the machine settings, reduce errors, and ensure quality control, which contributes to enhanced productivity.

Moreover, laser tables offer flexibility that traditional manufacturing methods often lack. They can handle a variety of materials, including metals, plastics, and wood, making them suitable for diverse applications. This versatility enables manufacturers to adapt more rapidly to changing market demands and to experiment with new designs without the need for extensive retooling.

Tip: Regularly assess your production needs and evaluate the material types you utilize. This can guide you in selecting the right laser table technology that aligns with your operational goals, ensuring you achieve the maximum efficiency and cost savings.

Exploring the Future of Manufacturing with Laser Table Technology - Impact of Laser Table Technology on Manufacturing Efficiency and Productivity Metrics

| Metric | Before Laser Table Technology | After Laser Table Technology | Percentage Improvement |

|---|---|---|---|

| Production Speed (units/hour) | 45 | 78 | 73.33% |

| Material Utilization (%) | 85 | 95 | 11.76% |

| Production Downtime (%) | 12 | 5 | 58.33% |

| Labor Costs (% of Total Costs) | 30 | 20 | 33.33% |

| Customer Satisfaction Score (out of 10) | 7.2 | 8.9 | 23.61% |

Advancements in Laser Technology: Innovations Enhancing Precision and Speed in Production

The demand for efficient and precise material processing solutions is driving the adoption of fiber laser technology across various industries, including automotive, electronics, and aerospace. According to recent market research, the global fiber laser market is projected to reach USD 6 billion by 2025, expanding at a CAGR of over 12% during the forecast period. This growth is primarily fueled by the need for high-quality manufacturing processes that can meet the stringent requirements of modern production environments.

Laser technology advancements have significantly enhanced precision and speed in production. With capabilities to cut, engrave, and weld materials with unmatched accuracy, fiber lasers are revolutionizing traditional manufacturing methods. For instance, their ability to process reflective materials and various thicknesses without compromising quality is making them increasingly preferred in applications where precision is paramount. Moreover, the reduction in operational costs due to lower maintenance and energy consumption is attracting manufacturers looking for sustainable solutions.

As industries continue to evolve, the integration of advanced laser systems will likely play a crucial role in shaping the future of manufacturing. Investments in research and development are expected to lead to innovations that further enhance the capabilities of laser technology, ensuring manufacturers remain competitive in an ever-demanding market.

Economic Implications: Cost-Effectiveness of Adopting Laser Table Systems in Manufacturing

The adoption of laser table technology in manufacturing processes presents significant economic implications, particularly regarding cost-effectiveness. As industries seek to enhance production efficiencies and reduce operational expenditures, laser table systems offer a promising solution. These systems, known for their precision and speed, minimize material waste and enhance the overall quality of products. By reducing the need for extensive manual labor and decreasing the time required for complex cuts, manufacturers can redirect resources toward other critical areas, thereby optimizing labor costs.

Moreover, the upfront investment in laser table systems can lead to substantial long-term savings. As businesses leverage these advanced technologies, they often experience a reduction in maintenance costs due to the durability and reliability of laser equipment. Additionally, the ability to quickly adapt to changing production demands without significant workflow disruptions allows manufacturers to remain competitive in a fast-paced market. The resulting increase in production volume combined with decreased operational costs highlights the compelling financial advantages of integrating laser table technology into modern manufacturing processes.

Exploring the Future of Manufacturing with Laser Table Technology

This chart illustrates the cost-effectiveness of adopting laser table systems in manufacturing over a ten-year period, showcasing potential savings compared to traditional manufacturing methods.

Sustainability in Manufacturing: How Laser Tables Reduce Waste and Energy Consumption

As the manufacturing industry continues to evolve, laser table technology emerges as a key player in enhancing sustainability. By utilizing high-precision lasers for cutting and engraving, manufacturers can significantly minimize material waste. Traditional methods often result in excess scrap, but laser tables optimize the cutting process, ensuring that maximized material utilization translates into reduced environmental impact.

Moreover, laser tables contribute to energy efficiency in manufacturing operations. The precision of laser cutting requires less power compared to older techniques, leading to lower energy consumption overall. This not only lowers operating costs but also reduces the carbon footprint of manufacturing activities. With the increasing emphasis on environmentally responsible practices, investing in laser table technology is a stride toward a greener future.

Tips: When considering the integration of laser tables into your manufacturing process, assess your current waste levels and energy usage to determine potential improvements. Regular maintenance of laser equipment can enhance performance and further reduce energy consumption. Additionally, training staff on best practices can ensure that your team makes the most of this advanced technology, contributing to sustainable manufacturing goals.

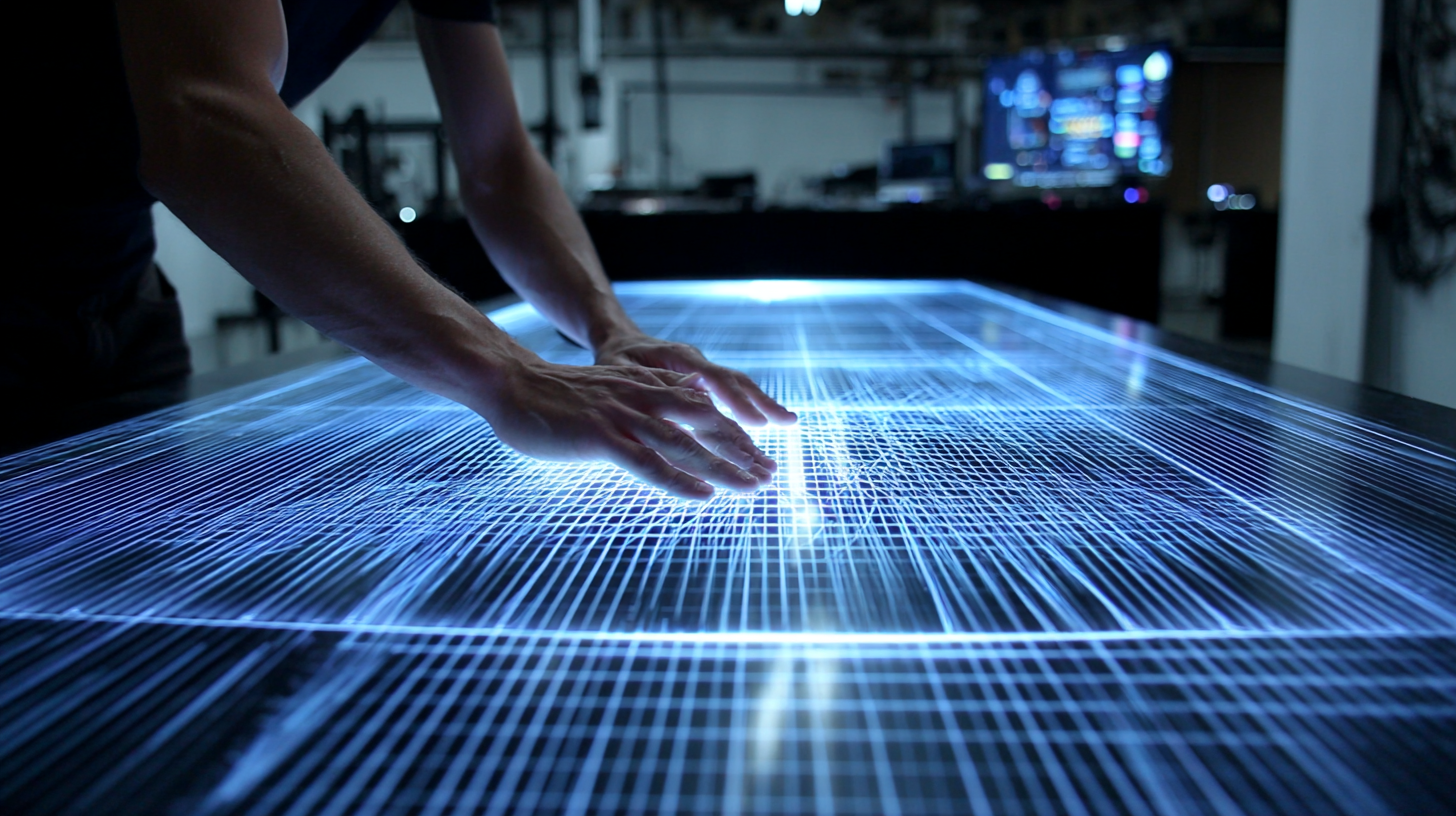

Future Trends: Predictive Analytics and Automation Integration with Laser Table Technology

The integration of predictive analytics into laser table technology is revolutionizing the manufacturing sector by enhancing efficiency and reducing waste. By leveraging vast amounts of data collected from production processes, manufacturers can anticipate potential failures and optimize machine performance in real-time. This proactive approach not only ensures smooth operations but also extends the lifespan of equipment, leading to significant cost savings and increased productivity.

Moreover, the incorporation of automation with laser table technology is streamlining workflows and minimizing human error. As advanced robotics and machine learning algorithms become more prevalent, the precision of laser cutting and engraving processes improves, allowing for complex designs to be harnessed effortlessly. This synergy between predictive analytics and automation paves the way for smart manufacturing environments, where data-driven decisions lead to higher quality outputs and rapid response to market demands, ultimately transforming the future landscape of manufacturing.

Related Posts

-

What is the Advantage of Using a CNC Router for Your Business

-

Unlocking the Future of Manufacturing Through Laser Machining Innovations and Trends

-

Exploring Market Trends: Stainless Steel Laser Engraving at the 138th Canton Fair 2025

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Unlocking the Power of Laser Etching in Modern Manufacturing