10 Essential Tips for Successful Laser Engraving on Metal

Laser engraving on metal has emerged as a vital processing technique in various industries, driven by its precision and versatility. According to market research, the global laser engraving market is expected to reach USD 5.78 billion by 2025, growing at a CAGR of approximately 6.29%. This growth is attributed to the increasing demand for customized products across sectors such as automotive, manufacturing, and jewelry. The ability to create intricate designs and markings on metal surfaces has made laser engraving a preferred choice for businesses aiming to enhance product differentiation and branding.

In terms of applications, laser engraving metal finds utility in marking serial numbers, logos, and decorative patterns, providing both functional and aesthetic value. Studies indicate that the metal engraving process offers superior durability and resistance compared to traditional methods, ensuring that engravings withstand wear and tear over time. Furthermore, with advancements in laser technology, such as fiber lasers, the quality and efficiency of metal engraving have significantly improved, allowing for faster production rates and reduced operational costs.

To harness the full potential of laser engraving metal, it is crucial to understand the techniques, materials, and settings that yield optimal results. This article will discuss ten essential tips that can help both novices and experienced operators achieve successful outcomes in their laser engraving projects on metal, enhancing both quality and productivity in their work.

Understanding the Basics of Laser Engraving on Metal

Laser engraving on metal is a precise and versatile technique used in various industries, from manufacturing to artistry. Understanding the basics of this technology is crucial for achieving successful results. According to a market report by MarketsandMarkets, the global laser engraving market is expected to grow from $4.3 billion in 2020 to $5.9 billion by 2025, representing a compound annual growth rate (CAGR) of 6.5%. This growth underscores the increasing adoption of laser engraving due to its efficiency, accuracy, and ability to produce intricate designs on durable materials like stainless steel, aluminum, and brass.

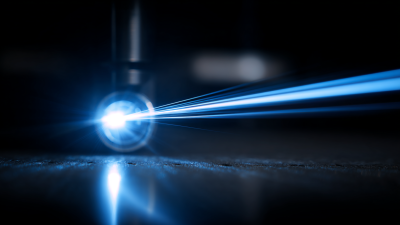

The fundamental principle behind laser engraving involves the use of focused laser beams to remove layers of material from the surface of the metal, creating a permanent mark. Factors such as laser type, power settings, and speed of engraving play a significant role in the quality of the final product. Data from a recent research study indicates that optimizing these parameters can lead to improved engraving depth and clarity, enhancing the overall aesthetic and functional value of the engraved metal products. Choosing the right type of laser—diode, fiber, or CO2—based on the specific metal and project requirements is also critical to success in this field. With the right understanding of these basics, enthusiasts and professionals alike can leverage laser engraving to create stunning results on metal.

Laser Engraving on Metal: Key Factors for Success

Choosing the Right Type of Metal for Engraving Projects

When it comes to laser engraving on metal, choosing the right type of metal is crucial for achieving optimal results. Different metals have unique properties that affect the engraving process, including their hardness, reflectivity, and thermal conductivity. For instance, softer metals like aluminum and brass are ideal for detailed engravings as they allow for deeper penetration of the laser. These materials not only provide excellent contrast when engraved but also ensure that intricate designs are captured accurately.

On the other hand, harder metals such as stainless steel and titanium may require more powerful lasers and specific settings to produce clean and precise engravings. While these metals are durable and resistant to corrosion, their hardness can present challenges during the engraving process. It is essential to consider the type of finish desired, as some metals respond better to certain techniques. For example, anodized aluminum provides a colorful background for engravings, while brushed stainless steel offers a sleek, modern look that enhances visibility. Understanding the characteristics of each metal will enable you to choose the best option for your specific engraving project, ultimately leading to stunning and professional results.

Essential Equipment and Tools for Laser Engraving

When embarking on a laser engraving project on metal, having the right equipment and tools is crucial for success. A reliable laser engraver is at the heart of your setup. Look for a machine that suits your specific needs, whether it’s a CO2 or fiber laser, as each type offers distinct advantages depending on the metal being engraved. Additionally, invest in high-quality lenses and mirrors to ensure precision and clarity in the engraving process.

In addition to your engraver, proper ventilation systems are essential to maintain a safe working environment. Fumes produced during the engraving process can be harmful, so integrating a fume extractor can prevent health risks. Moreover, using suitable metal marking compounds can enhance the quality of the engraving, allowing for better contrast and visibility.

Tip 1: Always test your settings on a scrap piece of metal before starting your final project. This helps you adjust speed, power, and frequency to achieve the desired outcome without compromising on quality.

Tip 2: Keep your equipment well-maintained. Regular cleaning of lenses and internal components helps to keep your engraver operating at peak performance, reducing the risk of errors during your engraving projects.

Techniques for Preparing Metal Surfaces Before Engraving

Preparing metal surfaces before laser engraving is crucial for achieving optimal results. First, it’s essential to thoroughly clean the surface to remove any dirt, dust, or grease that could interfere with the engraving process. Depending on the type of metal, using a degreaser or an appropriate solvent can help ensure that the surface is free of contaminants. For metals prone to oxidation, such as aluminum, using a non-abrasive cleaner can be especially effective in restoring a clean, smooth surface that enhances the engraving quality.

In addition to cleaning, it's important to assess the surface finish of the metal. Smooth surfaces can yield finer details in engravings, while rough surfaces may lead to uneven results. Lightly sanding the metal with a fine grit can help achieve a more uniform texture. After sanding, it's essential to clean the metal again to remove any particles generated during the process. Finally, applying a protective coating can further prepare the surface, particularly if the engraved item is intended for outdoor use or exposure to harsh conditions. This step not only enhances the engraving's visibility but also ensures the longevity of the design.

Safety Precautions When Working with Laser Engraving Machines

When working with laser engraving machines, safety should always be the top priority. According to the Occupational Safety and Health Administration (OSHA), many industries have reported accidents related to laser equipment, highlighting the need for stringent safety measures. Ensuring that operators use appropriate personal protective equipment (PPE) like safety goggles specifically designed for laser work is essential. These goggles help shield the eyes from harmful laser radiation, reducing the risk of permanent eye damage.

Additionally, proper ventilation is vital when operating laser engraving machines. Wood, metals, and plastics can emit harmful fumes and particulates when engraved, which can pose respiratory hazards. A ventilation system that effectively removes these contaminants not only protects the operator’s health but also enhances the quality of the engraving process. Regular maintenance of the machine, including cleaning and inspecting for any wear or damages, is also crucial to prevent malfunctions that could lead to accidents.

For optimal results, consider these essential tips: always ensure that the workspace is clean and free of clutter to minimize fire hazards; familiarize yourself with your laser machine's operation manual to understand its safety features; and conduct regular training sessions for all operators to keep safety protocols fresh in their minds. By prioritizing safety and adopting best practices, you can significantly reduce risks associated with laser engraving on metal and maintain a productive working environment.

Related Posts

-

How to Set Up Router Tables for Perfect Woodworking Projects

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

How to Choose the Best Laser Table for Your Cutting Needs

-

Exploring Laser Machining Innovations at China Import and Export Fair 2025

-

What is the Advantage of Using a CNC Router for Your Business