How to Effectively Utilize Metal Laser Cutting for Your Projects

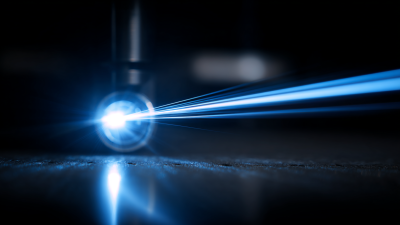

In the ever-evolving landscape of manufacturing and design, metal laser cutting has emerged as a pivotal technology that offers unparalleled precision and efficiency. This innovative process harnesses the power of laser beams to cut through various kinds of metals with exceptional accuracy, making it an indispensable tool for engineers, fabricators, and hobbyists alike. As projects become increasingly complex, understanding how to effectively utilize metal laser cutting not only enhances the quality of the final product but also leads to significant reductions in material waste and operational costs.

The versatility offered by metal laser cutting allows for intricate designs that were once deemed too complex or time-consuming to achieve with traditional cutting methods. By mastering this technique, project managers and designers can push the boundaries of their creativity, transforming ideas into elegant, tangible artifacts with relative ease. This introduction aims to explore the best practices for leveraging metal laser cutting technology, ensuring that you can maximize its potential in your own projects. As we delve deeper into the mechanics and applications of this cutting-edge method, you will gain valuable insights that can elevate your work and streamline production processes.

Understanding Metal Laser Cutting Technology and Its Applications

Metal laser cutting technology has revolutionized the way we approach manufacturing and design across various industries. At its core, the process utilizes focused laser beams to cut or engrave metal with precision and accuracy. This technology is defined by its ability to produce intricate designs while minimizing material waste, making it a preferred choice for both large-scale production and bespoke projects. The versatility of laser cutting extends across a range of metals, including steel, aluminum, and titanium, allowing for diverse applications in sectors such as automotive, aerospace, and construction.

One of the significant advantages of laser cutting is its adaptability to complex geometries. Designers can create detailed shapes and patterns that would be challenging to achieve through traditional cutting methods. This precision not only enhances the aesthetic quality of products but also improves their structural integrity. Additionally, the speed and efficiency of laser cutting reduce operational costs and lead times, making it an appealing option for businesses looking to streamline their production processes. As industries continue to evolve, understanding the capabilities and applications of metal laser cutting technology will be crucial for leveraging its benefits effectively.

How to Effectively Utilize Metal Laser Cutting for Your Projects

| Application | Material Type | Thickness Range (mm) | Precision Level | Speed (mm/min) |

|---|---|---|---|---|

| Automotive Parts | Steel | 1-20 | ±0.05 | 2000 |

| Aerospace Components | Aluminum | 0.5-10 | ±0.03 | 1500 |

| Architectural Accents | Stainless Steel | 1-15 | ±0.1 | 1200 |

| Consumer Electronics | Brass | 0.5-5 | ±0.02 | 3000 |

| Industrial Machinery | Carbon Steel | 1-25 | ±0.05 | 1800 |

Key Benefits of Using Metal Laser Cutting in Various Industries

Metal laser cutting has gained immense popularity across various industries due to its precision, speed, and versatility. One of the key benefits of utilizing this technology is the exceptional accuracy it offers, allowing manufacturers to create intricate designs and complex shapes with minimal material wastage. This is particularly advantageous in the automotive and aerospace sectors, where even the slightest error could lead to costly rework or production delays.

In addition to precision, laser cutting provides a cleaner cutting edge compared to traditional methods, resulting in reduced finishing time. This efficiency is crucial in the fabrication industry, where time is often a critical factor. By adopting metal laser cutting, businesses can enhance their production capabilities and increase overall productivity without compromising on quality.

**Tips:** When integrating laser cutting into your projects, ensure that you select the right type of laser based on the material and thickness. Additionally, regularly maintain your cutting equipment to avoid downtime and achieve optimal performance. Finally, consider investing in training for your staff to fully harness the potential of metal laser cutting technologies.

Essential Factors to Consider When Choosing Laser Cutting Services

When selecting laser cutting services for your metal projects, several essential factors must be taken into account to ensure optimal results. First, the type of metal you plan to cut plays a crucial role in the choice of service provider. Different metals, such as stainless steel, aluminum, or carbon steel, require varying laser intensities and cutting techniques. Therefore, it is important to inquire whether the service provider has the necessary expertise and equipment to handle your specific material efficiently.

Another important consideration is the precision and quality of the cutting capabilities. Look for services that use advanced laser technology, as this ensures cleaner cuts and minimizes waste. In addition, ask for samples or references of previous work to assess their cutting quality.

Service providers with a strong reputation for precision will be invaluable in achieving the specific tolerances and finishes that are critical for your project's success. Finally, don't overlook turnaround times and customer support; effective communication and timely delivery are paramount in keeping your project on track.

Insights into the Precision and Speed of Metal Laser Cutting Processes

Metal laser cutting has revolutionized the manufacturing and fabrication industries, offering unparalleled precision and speed. This technology utilizes focused laser beams to cut through various metals, achieving intricate designs that traditional methods struggle to replicate. The ability to control the laser's intensity and focus allows for fine adjustments, resulting in clean edges and minimized material waste. This level of accuracy is crucial for projects that require tight tolerances, such as aerospace components, automotive parts, and intricate architectural features.

In addition to precision, the speed of metal laser cutting processes significantly enhances productivity. Unlike conventional cutting methods that rely on mechanical processes, laser cutting can operate continuously, reducing operational downtime. The rapid processing times allow for quick prototyping and faster turnaround for production runs, making it a preferred choice for industries that demand efficiency without compromising on quality. As a result, businesses can respond more swiftly to market demands, leading to reduced lead times and increased competitiveness in their respective fields. This combination of speed and precision makes metal laser cutting an essential tool for modern projects.

Efficiency of Metal Laser Cutting Processes

Cost Analysis: Budgeting for Metal Laser Cutting Projects Effectively

When planning a metal laser cutting project, an effective cost analysis is crucial for ensuring that budgets are allocated wisely. Begin by evaluating the specific requirements of your project, such as the type of metal, thickness, and intricacy of the design. These factors will influence the total cost significantly, including material expenses and the time required for the cutting process. By having a clear understanding of the project scope, you can better estimate the resources needed, which will prevent unexpected expenses later on.

In addition to direct costs, consider the potential hidden expenses associated with metal laser cutting projects. These may include setup fees, transportation of materials, and labor costs for both production and assembly. It's also wise to factor in the equipment maintenance or rental costs if you do not own a suitable laser cutter. By compiling all these elements into a comprehensive budget, you can achieve more accurate financial forecasting and effectively allocate funds, ensuring that your project stays within budget while maintaining quality standards.

Related Posts

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive