What is a Cutting Table and How is it Used in Various Industries?

A cutting table is a fundamental tool in various industries, including textiles, woodworking, and manufacturing. This versatile piece of equipment provides a stable surface for precise cutting. It can come in various sizes and designs, tailored to specific tasks and materials. The cutting table is not just a flat surface; it often features measurements and guides to aid accuracy.

In the textile industry, large cutting tables facilitate the precision cutting of fabric layers. Workers can align patterns and ensure minimal waste. Similarly, in woodworking, cutting tables allow craftsmen to achieve clean, straight cuts on boards. The effectiveness of a cutting table can significantly influence the quality of the finished product. However, many professionals overlook its proper setup and maintenance.

Not every cutting table is suitable for every task. Choosing the wrong table can lead to inefficiencies. Sometimes, operators find themselves battling against poorly designed surfaces. These challenges highlight the importance of selecting and using the right cutting table for each specific job.

What is a Cutting Table? Definition and Key Features

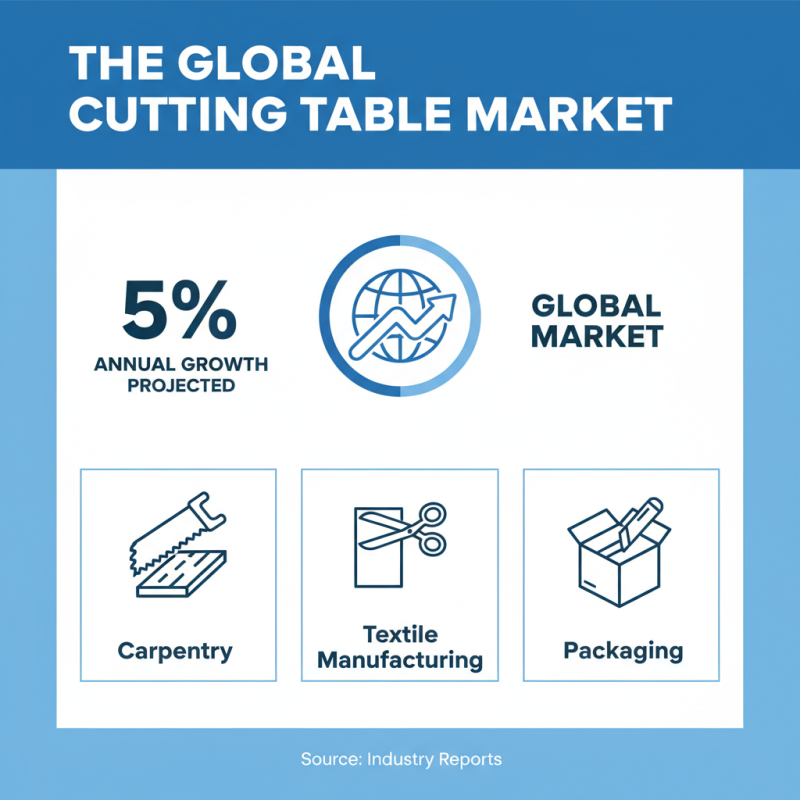

A cutting table is an essential tool in various industries. It is designed to streamline the process of cutting materials. Typically, these tables are large, flat surfaces, often equipped with measurements for accurate cutting. They are crucial in carpentry, textile manufacturing, and even packaging. According to industry reports, the global market for cutting tables is projected to grow by 5% annually.

Key features of cutting tables include durability and precision. Many tables come with adjustable heights, ensuring ergonomic use. Some models have built-in cutting tools or guides to enhance accuracy. In textiles, for instance, fabric can be laid out flat, allowing multiple layers to be cut simultaneously. This efficiency can increase production speed and reduce waste.

Tips: Always ensure that the cutting surface is clean and free of debris. This prevents mistakes and ensures cuts are precise. Regular maintenance of the cutting tools also extends the life of the table. Keep in mind, though, that not all tables are created equal. Some can warp over time or become less reliable with heavy use. It’s vital to assess your needs and choose accordingly.

The Role of Cutting Tables in the Textile Industry: Precision and Efficiency

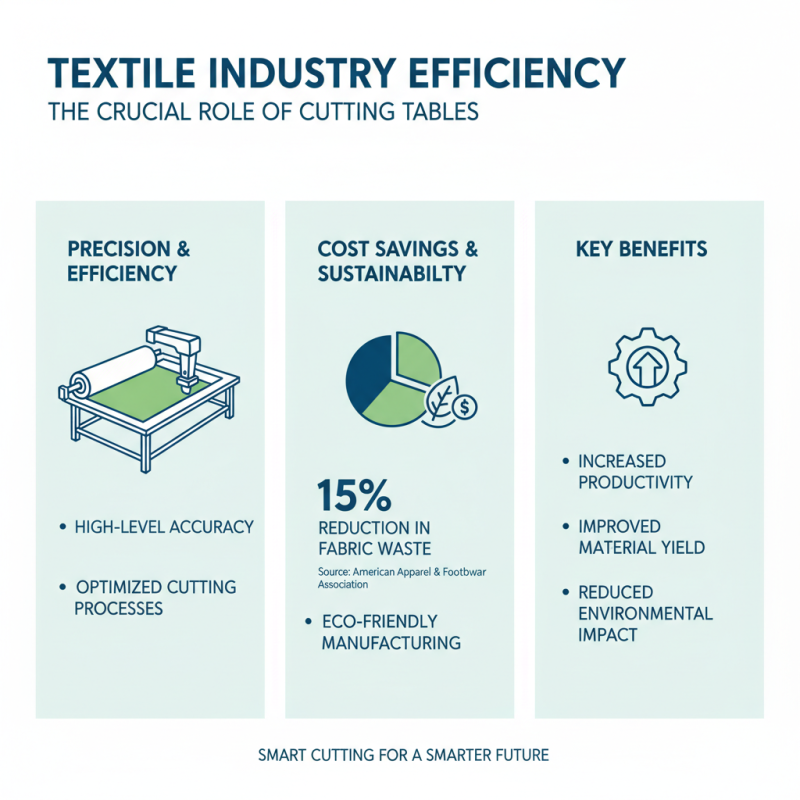

Cutting tables play a crucial role in the textile industry. They are essential for achieving high levels of precision and efficiency in fabric cutting. A well-designed cutting table can significantly reduce fabric waste, which is critical given the rising costs of materials. According to a recent report by the American Apparel & Footwear Association, efficient cutting methods can decrease fabric waste by up to 15%. This not only saves costs but also helps in promoting sustainability.

In a fast-paced production environment, speed is key. A cutting table allows for quick setup and adjustments. High-tech cutting tables can accommodate various fabric types, adapting to different thicknesses. For example, some models can handle both delicate silk and heavy denim. However, not all facilities invest in advanced technology. Many still rely on traditional methods, resulting in inefficiencies. This gap highlights the need for ongoing training in cutting techniques. Without proper training, even the best equipment can lead to errors and increased material costs.

Businesses face pressure to keep up with market demands. Achieving the right balance between speed and accuracy can be challenging. The textile industry must reflect on its practices. Continuous improvements in cutting methods are necessary for enhanced productivity. Investing in better cutting tables and staff training can lead to transformative results.

Applications of Cutting Tables in the Furniture Industry: Design and Production

Cutting tables are essential tools in the furniture industry. They provide a flat, stable surface for cutting various materials. These tables can handle wood, fabric, and even metal sheets. Craftsmen and designers rely on cutting tables for precision. Accurate cuts lead to better fits and finishes.

When designing furniture, time management is critical. Here are some tips: Always measure twice before cutting. A slight mistake can lead to significant waste. Use sharp blades for clean cuts. Dull blades can ruin the material.

In production, efficiency matters. Organize your workspace. Keep tools nearby and materials in order. This minimizes distractions and errors. Consider using a cutting table with adjustable heights. It can increase comfort during long hours of work. Remember, maintaining your cutting table is vital. Regular cleaning and minor repairs contribute to its longevity.

Advancements in Cutting Table Technology: Automation and Innovation

Cutting tables have evolved significantly with advancements in technology. Nowadays, automation plays a crucial role in their functionality. Industries like textile, woodworking, and automotive have embraced these innovations. Automated cutting processes reduce human error. They also increase efficiency and precision. These tables often feature integrated software that optimizes cutting paths. This results in less material waste and improved productivity.

When considering a cutting table, think about the materials it will handle. Not all tables are suitable for every application. It's essential to select a table that meets specific industry needs. Learning from past purchases can be enlightening. Some users find their initial decisions flawed. Reflecting on those choices can lead to better future investments.

Incorporating innovative features in cutting tables can enhance usability. Advanced models come with built-in scanners and CAD integration. Such features streamline the workflow. However, training is often needed to harness their full potential. It’s important to invest time in understanding these technologies. Skipping this step could lead to underutilization of the equipment.

Usage of Cutting Tables in Different Industries

Safety Standards and Best Practices for Using Cutting Tables in Workshops

Cutting tables are essential tools in various industries, from textiles to woodworking. They provide a stable surface for precise cutting. However, using these tables comes with safety risks. According to the National Institute for Occupational Safety and Health (NIOSH), improper handling of cutting tools leads to thousands of injuries annually. Practicing safety standards can significantly reduce these risks.

Workers must wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and protective footwear. It's also critical to maintain a clean workspace. A cluttered environment increases the chance of accidents. Regular inspections of cutting tables can help identify wear and tear. Yet, many workshops overlook this, creating potential hazards.

Training is vital for safe operations. Many employees lack awareness of cutting hazards. A recent survey indicated that nearly 40% of workers did not receive formal training. This gap shows the need for structured safety programs. Moreover, following manufacturer guidelines for tools and tables is crucial. Not all practices are universally relevant, as each industry has unique requirements. Building a culture of safety is the responsibility of every workshop.

What is a Cutting Table and How is it Used in Various Industries?

| Industry | Usage of Cutting Tables | Safety Standards | Best Practices |

|---|---|---|---|

| Textile | Cutting fabric for garments | Ensure proper ventilation | Regular maintenance and blade sharpening |

| Woodworking | Ripping and crosscutting wood panels | Dust collection systems must be used | Use push sticks for safety |

| Metal Fabrication | Cutting sheets of metal for assembly | Protective eyewear and gloves are mandatory | Keep cutting area clear of obstruction |

| Packaging | Trimming boxes and cartons | Adhere to ergonomic standards | Training for employees on safe cutting techniques |

Related Posts

-

Maximize Your Workspace: The Ultimate Guide to Choosing the Perfect Cutting Table

-

Maximizing Your Workspace Efficiency with the Right Cutting Table for Your Crafting Needs

-

How to Choose the Best Cutting Table for Your Crafting Needs

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects