What is a CNC Router? Understanding Its Uses and Advantages in Various Industries

In the rapidly evolving landscape of manufacturing and design, the CNC router has emerged as a pivotal tool across various industries. These advanced machines, which utilize computer numerical control technology to guide cutting tools with precision, have revolutionized processes in woodworking, metal fabrication, and even creative arts. According to John Smith, a leading expert in CNC technology, "The CNC router not only enhances efficiency but also opens up new avenues for creativity and innovation in manufacturing."

The versatility of CNC routers is one of their most significant advantages. Whether it’s producing intricate designs in furniture making or crafting detailed prototypes for engineering projects, these machines provide unmatched accuracy and repeatability. As industries continue to seek ways to streamline production and reduce costs, understanding the capabilities and applications of CNC routers becomes essential for professionals looking to leverage technology effectively.

Furthermore, the benefits of CNC routers extend beyond mere efficiency. They also allow for customization and adaptability, enabling businesses to respond swiftly to market demands and consumer preferences. As we delve into the multifaceted uses and advantages of CNC routers, it is clear that these machines are not just tools of production but catalysts for innovation across various sectors.

What is a CNC Router? An Overview of the Technology and Its Components

A CNC (Computer Numerical Control) router is an advanced fabrication tool that operates through the automation of cutting and drilling processes. The technology utilizes computer-aided design (CAD) software to translate designs into precise movements of the router's cutting bit. Fundamentally, CNC routers consist of several key components: the machine itself, a spindle for cutting, controllers for operation, and software for programming. This integration allows manufacturers to achieve high levels of accuracy, speed, and repeatability in their production processes.

In various industries—ranging from woodworking to aerospace—a significant shift towards CNC routing technology has been observed. According to a report by Research and Markets, the global CNC router market is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by the increasing demand for precision cutting in manufacturing. The flexibility and scalability offered by CNC routers enable companies to produce intricate designs and complex shapes that were previously difficult or impossible to achieve with traditional machining methods. This adaptability not only enhances productivity but also reduces material waste, making CNC routing a sustainable choice for modern manufacturing practices. With its ability to streamline operations and improve output quality, CNC routing technology continues to revolutionize various sectors, positioning itself as an essential tool in contemporary industrial settings.

Comparative Analysis: CNC Routers versus Traditional Machining Methods

CNC routers have gained significant traction in various industries due to their precision and efficiency when compared to traditional machining methods. According to a report by MarketsandMarkets, the CNC machine market is projected to reach USD 117.6 billion by 2026, driving the adoption of CNC routers in manufacturing sectors. Unlike conventional machining, which often relies on manual operation and can be prone to human error, CNC routers utilize computer-controlled processes that enhance accuracy. For example, CNC routers can achieve tolerances within 0.01 mm, which is particularly beneficial in industries such as aerospace and automotive, where precision is paramount.

Moreover, CNC routers offer greater flexibility in design and material usage. Traditional machining methods are typically limited to specific materials and require extensive tooling changes for different jobs, often resulting in longer lead times. In contrast, CNC routers can work with a variety of materials—such as wood, plastics, and metals—with minimal setup time. A 2020 study by the International Journal of Advanced Manufacturing Technology noted that companies employing CNC routers saw a 30% reduction in production time compared to traditional machining approaches. These advantages, along with the ability to produce complex geometries, make CNC routers a vital asset in modern manufacturing processes.

Applications of CNC Routers in Woodworking and Furniture Manufacturing

CNC routers have revolutionized the woodworking and furniture manufacturing industries, providing precision and efficiency that traditional methods cannot match. These automated machines utilize computer numerical control to achieve intricate designs and cuts, allowing manufacturers to create complex shapes and patterns with ease. In woodworking, CNC routers can process various materials, from hardwoods to softwoods and even plywood, making them an essential tool for crafting everything from cabinets to customized furniture pieces.

The applications of CNC routers in furniture manufacturing are particularly diverse. They enable the mass production of components, such as tabletops, chair legs, and decorative elements, while maintaining high-quality standards. This technology not only speeds up the production process but also reduces material waste through optimized cutting techniques. Additionally, CNC routers can facilitate customization, empowering designers to experiment with unique styles and finishes, thereby enhancing the overall aesthetic appeal of furniture items.

As a result, CNC routers have become indispensable in delivering both efficiency and creativity to the woodworking sector.

The Role of CNC Routers in Aerospace and Automotive Industries

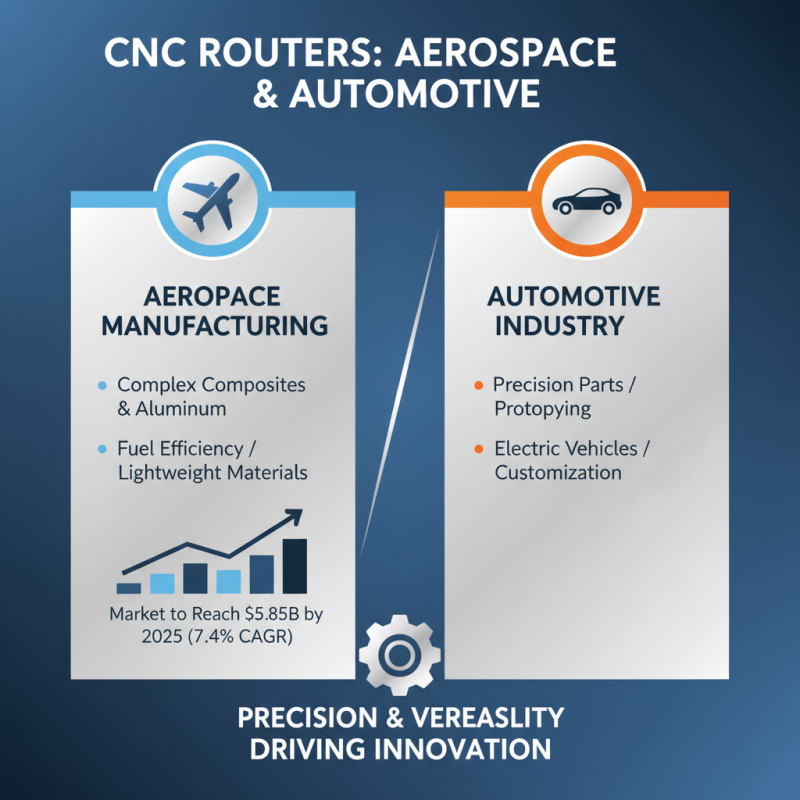

CNC routers have become essential tools in the aerospace and automotive industries due to their precision and versatility. In aerospace manufacturing, CNC routers are crucial for shaping complex materials such as composites and aluminum, which are commonly used in aircraft components. According to a report by MarketsandMarkets, the aerospace CNC machining market is expected to reach $5.85 billion by 2025, growing at a CAGR of 7.4% from 2020. This growth is largely driven by the increasing demand for lightweight materials that improve fuel efficiency, which CNC routers can effectively handle.

In the automotive sector, CNC routers facilitate the manufacturing of intricate parts for vehicles, allowing for both mass production and custom job requirements. The global automotive industry is projected to witness a rapid shift towards electrification and automation, leading to a greater need for precision-engineered components. A study by Research and Markets indicates that the automotive CNC machining market will grow to $18.8 billion by 2026, driven by advancements in technology and the rise of electric vehicles. The ability of CNC routers to achieve high tolerances and rapid prototyping is critical in supporting the fast-paced innovation seen in contemporary automotive design and production.

Economic Benefits: Cost Efficiency and Precision of CNC Routers in Production

CNC routers have revolutionized manufacturing processes across various industries by combining advanced technology with cost efficiency. These machines utilize computer numerical control to automate milling, drilling, and cutting processes, achieving high levels of precision that manual methods simply cannot match. This precision reduces material waste, as CNC routers minimize errors during production, leading to more economical use of raw materials. Moreover, the ability to produce consistent and repeatable results ensures that products meet strict quality standards, which is increasingly important in competitive markets.

The economic benefits of CNC routers extend beyond just material savings. Their speed of operation significantly enhances production efficiency, allowing businesses to fulfill orders more rapidly and respond to market demands swiftly. By streamlining the manufacturing process, companies can lower labor costs, as fewer operators are needed to manage and oversee production. Additionally, the reduced setup times for CNC routers mean that companies can switch between different projects with minimal downtime, further improving their overall productivity and profitability. Overall, the integration of CNC routers into production lines not only fosters innovation but also offers substantial cost benefits to businesses willing to embrace this technology.

Related Posts

-

What is the Advantage of Using a CNC Router for Your Business

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Top 10 Laser Cutting Tables for Precision and Efficiency in 2023

-

Unlocking the Power of Laser Etching in Modern Manufacturing