Why CNC Laser Cutting Is the Future of Precision Manufacturing?

CNC laser cutting is revolutionizing precision manufacturing. This advanced technology offers unmatched accuracy and efficiency. It's becoming the go-to method for various industries.

Imagine a machine that cuts through metal like butter. CNC laser cutting achieves intricate designs with minimal waste. It enables manufacturers to be more creative and precise. However, not all companies are embracing this technology yet. Some still rely on traditional methods. This reluctance can limit their growth potential.

The future belongs to those who adapt quickly. Embracing CNC laser cutting means embracing change. Businesses willing to invest in this technology will likely lead their fields. Yet, challenges exist, such as cost and training. Companies must reflect on these factors to stay competitive.

The Evolution of CNC Laser Cutting Technology in Manufacturing

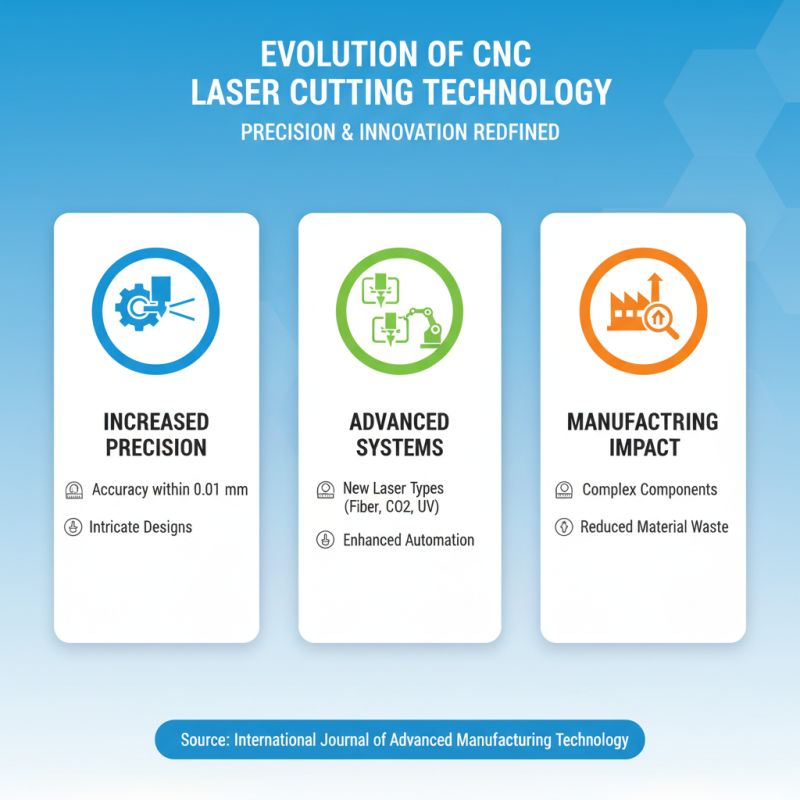

CNC laser cutting technology has evolved significantly in recent years. With advancements in laser types and automation, the precision of cuts has increased dramatically. According to a recent study by the International Journal of Advanced Manufacturing Technology, accuracy rates of laser cutting machines are now within 0.01 mm. This precision allows manufacturers to produce intricate designs that were once impossible.

The efficiency of CNC laser cutting also continues to improve. Recent statistics indicate that laser cutting can be up to three times faster than traditional cutting methods. This speed is vital in industries such as automotive and aerospace, where time-to-market is crucial. However, despite its advantages, challenges remain. Many manufacturers grapple with the high initial investment costs and the learning curve associated with new technology. These factors can hinder widespread adoption and require careful consideration.

As the demand for customization rises, CNC laser cutting will likely play a vital role in meeting these needs. However, companies must weigh these benefits against potential drawbacks. Achieving the perfect balance between cost and precision may require more reflection and strategic planning. The future of manufacturing seems to be leaning towards laser cutting, but it is not without its hurdles.

Key Advantages of CNC Laser Cutting Over Traditional Methods

CNC laser cutting is changing how we approach precision manufacturing. This technology offers remarkable advantages compared to traditional methods. One key benefit is its ability to cut intricate designs with unparalleled accuracy. Laser cutting can achieve finer details than blade cutting. Many industries rely on this precision for creating complex components.

Another factor to reflect on is the learning curve. Machine operators must be trained properly to ensure efficient use. Incorrect settings can lead to defects. This contrasts with traditional methods, which may require less specialized knowledge. As companies adapt, they may face challenges in workforce training. Balancing speed, accuracy, and employee skill will be important for success.

Applications of CNC Laser Cutting in Various Industries

CNC laser cutting is transforming various industries with its precision and efficiency. In the automotive sector, manufacturers utilize CNC laser cutting for creating intricate parts. Reports show that laser cutting can increase cutting speed by 50% compared to traditional methods. This efficiency leads to reduced production time and lower costs.

In the aerospace industry, lightweight components are crucial. CNC laser cutting allows for precise cuts that minimize material waste. According to industry studies, adopting laser cutting technology can save up to 30% in material costs. Additionally, the ability to create complex shapes without compromising strength is a game changer.

The medical field also benefits from this technology. Surgical instruments require precision and sterility. CNC laser cutting can produce instruments with tight tolerances, ensuring patient safety. However, the initial investment in laser equipment can be high. Companies must weigh this cost against potential long-term savings and improved accuracy. The transition may not be seamless, but the results often justify the effort.

Challenges and Limitations of CNC Laser Cutting Technology

CNC laser cutting technology promises accuracy and efficiency in manufacturing. However, it is not without its challenges. One significant limitation is material compatibility. Not all materials can be seamlessly cut by lasers. Certain metals may reflect the laser, causing inefficiencies. Additionally, thickness plays a crucial role. Thicker materials can be more difficult and time-consuming to cut.

Another challenge is the cost of maintenance. CNC laser machines require regular upkeep and repairs. Neglecting maintenance can lead to diminished performance and costly downtime. Not every shop can afford unexpected repairs, which can disrupt production schedules.

**Tip:** Regularly inspect and clean your equipment to extend its lifespan.

Operators must also be trained properly. Inexperienced users may struggle and make costly mistakes. Understanding the programming and operation is essential for optimal use.

**Tip:** Invest in training programs for your team. This can reduce errors and improve productivity.

Despite these challenges, the benefits of CNC laser cutting are significant. Continued advancements may help mitigate these limitations over time. Embracing new technologies is a journey, marked by learning and adaptation.

Challenges and Limitations of CNC Laser Cutting Technology

Future Trends and Innovations in CNC Laser Cutting Systems

CNC laser cutting technology is rapidly evolving. This method can achieve tolerances within 0.01 mm, enhancing precision in manufacturing. According to a report by Mordor Intelligence, the CNC laser cutting market is projected to grow at a CAGR of 7.5% from 2021 to 2026. This momentum reflects the increasing demand for high-precision components across various industries, including aerospace and automotive.

Recent innovations include advancements in fiber laser technology. Fiber lasers are becoming more popular due to their efficiency and lower operational costs. They also generate less waste, which aligns with sustainability trends. However, embracing such innovations can pose challenges. Not all manufacturers can keep pace with technology upgrades or hire skilled operators. This inconsistency may lead to a skills gap that hinders growth.

Additionally, the integration of automation and AI in CNC laser cutting systems is under discussion. This technological synergy can reduce production time and improve accuracy. Despite the potential, many businesses struggle with the initial investment and training. Companies must weigh the benefits against these challenges to fully capitalize on the future of CNC laser cutting.

Related Posts

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023