How to Choose the Right CNC Router Table for Your Projects?

When it comes to finding the perfect CNC router table, many factors come into play. Mike Johnson, a well-known expert in the CNC industry, once said, “Choosing the right CNC router table can make or break your project.” This statement rings true for both beginners and seasoned makers alike.

Understanding your specific needs is crucial. Will you be working with wood, plastic, or metal? Each material requires different features from a CNC router table. Brand reputation and customer reviews often guide decisions, yet they may not cover all aspects. This can lead to regret after a purchase.

Furthermore, consider the machine’s size and capabilities. An oversized table may seem appealing but can limit workspace. On the contrary, a compact design might restrict your creativity. Balance is key. Reflecting on these details can be the difference between success and frustration in your CNC endeavors.

Understanding CNC Router Tables and Their Applications

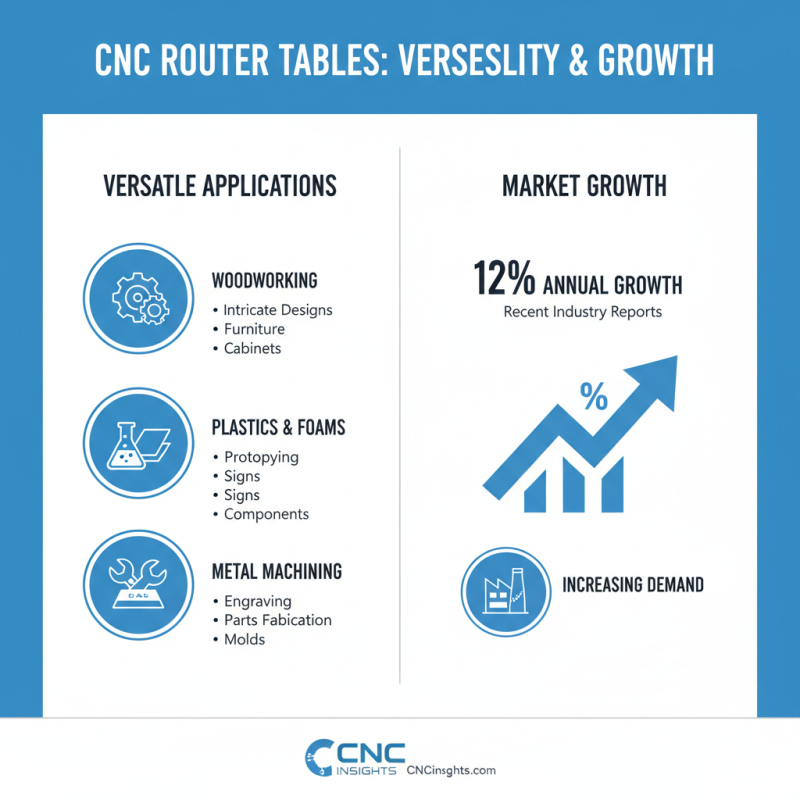

CNC router tables are versatile tools in woodworking and manufacturing. Their applications range from creating intricate designs to machining solid materials like wood, plastics, and metals. Recent industry reports indicate that the demand for CNC routers has grown by approximately 12% annually.

When selecting a CNC router table, consider its size and parameters. A common misstep is underestimating the workspace needed for larger projects. Measurements matter. Users often find they need more room than anticipated, leading to project delays. Additionally, material compatibility is crucial. Different tables handle various materials based on their power and design.

Precision is vital in CNC routing. Statistics show that about 30% of projects fail due to miscalculations in setup. Users need to verify their machine’s capabilities and calibrate accordingly. Even minor errors can lead to significant issues. Reflecting on past problems can improve future projects. Choosing the right CNC router table is about understanding specific needs and the materials involved. If uncertain, seek guidance or test different models to find the best fit.

Key Considerations When Selecting a CNC Router Table

When selecting a CNC router table, there are key considerations that can impact your projects. The size of the table is crucial. A larger table allows for bigger materials and more complex designs. If you often work with large sheets, opt for a spacious one. However, if space is limited in your workshop, a compact model may suit your needs better.

Think about the build quality too. Tables made from sturdy materials offer better stability and precision. Look for features such as reinforced frames and robust surfaces. A heavy table is generally less prone to vibrations, which can affect your cutting quality. Remember, light tables can sometimes be more portable but might not deliver the same accuracy.

Consider the routing depth and speed. Different projects require various depths of cuts. Check the specifications before making a decision. Speed settings matter, as well. Fast speeds can reduce time but may compromise detail. Reflect on your specific needs. Sometimes, it’s better to choose a table that offers more control, especially for intricate work.

Types of CNC Router Tables and Their Features

When exploring CNC router tables, one must consider various types and features. A stationary router table offers stability, making it ideal for large projects. These tables usually have a sturdy frame and ample workspace. They are suitable for cutting materials like wood and plastic.

Portable router tables provide flexibility. They are lightweight and can be moved easily. However, they may not have the same level of stability as stationary models. This could lead to inaccuracies if not used carefully. Users might find themselves adjusting settings frequently during projects.

Another option is the compact router table. It's designed for smaller spaces and quick setups. This table is perfect for hobbyists or those with limited room. Nonetheless, it can only handle smaller pieces, which might limit creativity. You might want to think about how much space you have before choosing. Each type has pros and cons; reflecting on your specific needs is crucial.

Budgeting for Your CNC Router Table Investment

When budgeting for a CNC router table, it’s essential to understand the cost spectrum. According to industry reports, entry-level models start around $1,000. Mid-range options often fall between $3,000 and $5,000. High-end professional machines can exceed $10,000. This wide range can be daunting. Assess your project needs carefully to ensure your investment aligns with your goals.

Tips: Consider the materials you plan to work with. Hardwoods may require more robust equipment. Don’t overlook maintenance and power costs, as these can add up over time. Researching software compatibility is also vital. The right software can enhance your machine’s capabilities.

Investing in a CNC router table demands reflection on usage. Are you running a small business or a hobby? Your primary focus will affect your budget. A hobbyist might opt for a less expensive model, but a growing business may need a more reliable machine. Always factor in future growth when planning your budget. The return on investment in quality equipment may justify the initial higher cost. Choose wisely, as your long-term satisfaction depends on it.

Budgeting for Your CNC Router Table Investment

This bar chart illustrates the average costs associated with different categories of CNC router tables. Understanding the budget for each category can help you choose the right CNC router table that fits your project needs.

Essential Accessories and Upgrades for CNC Router Tables

Choosing the right CNC router table involves more than just picking the right model. Essential accessories can enhance its functionality immensely. One significant accessory is the dust collection system. It keeps your workspace clean. A tidy area leads to better focus and accuracy. Without proper dust management, you may face visibility issues.

Another important upgrade is a sturdy spoil board. It helps secure materials firmly while routing. A spoil board can withstand repeated use and offers a flat surface for diverse projects. For more precision, consider adding a digital depth gauge. It ensures consistent cuts, but can be tricky to calibrate. A small miscalculation will lead to poor results.

Lastly, consider enhanced software options. They can provide new features, but sometimes might overcomplicate processes. It's essential to weigh the benefits against the learning curve. Improvements can be significant, but user experience varies. Careful research is crucial to make the most informed choices. Remember, each upgrade should align with your specific project needs.

How to Choose the Right CNC Router Table for Your Projects? - Essential Accessories and Upgrades for CNC Router Tables

| Dimension | Description | Recommended Size | Accessories |

|---|---|---|---|

| Working Area | The maximum size of material that can be processed. | 24" x 36" | Dust Collection System |

| Material Compatibility | Types of materials the CNC router can handle. | Wood, Plastic, Aluminum | Router Bits |

| Max Speed | The speed at which the spindle can operate. | 20,000 RPM | Speed Controller |

| Frame Material | The material used for the base and structure. | Steel or Aluminum | Stabilizing Feet |

| Controller Type | The interface used to control the CNC router. | USB/Parallel Port | Upgraded Software |

Related Posts

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects

-

What is the Advantage of Using a CNC Router for Your Business

-

What is a CNC Router? Understanding Its Uses and Advantages in Various Industries

-

Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

-

How to Choose the Best Laser Cut Parts for Your Project Needs