How to Choose the Best Metal Laser Cutting Service?

Choosing the best metal laser cutting service can be daunting. The industry is filled with options, and quality varies significantly. According to John Smith, a leading expert in metal laser cutting, "Precision and reliability are key in selecting a service that meets your needs." His insight emphasizes the importance of accuracy in this field.

When evaluating a potential service, consider their technology and expertise. Advanced machines ensure better cuts and faster turnaround times. Look for companies that invest in their equipment. This usually translates into higher-quality outputs. Furthermore, seek feedback from previous clients. Their experiences can provide valuable insights into a company’s reliability.

However, not all services deliver on their promises. Some may overstate their capabilities. It’s essential to ask for samples of previous work. Evaluate the quality of their cuts closely. Metal laser cutting should leave smooth edges and precise designs. Finding a trustworthy partner demands effort and thorough research. Aim for a service that not only meets technology but also values customer satisfaction.

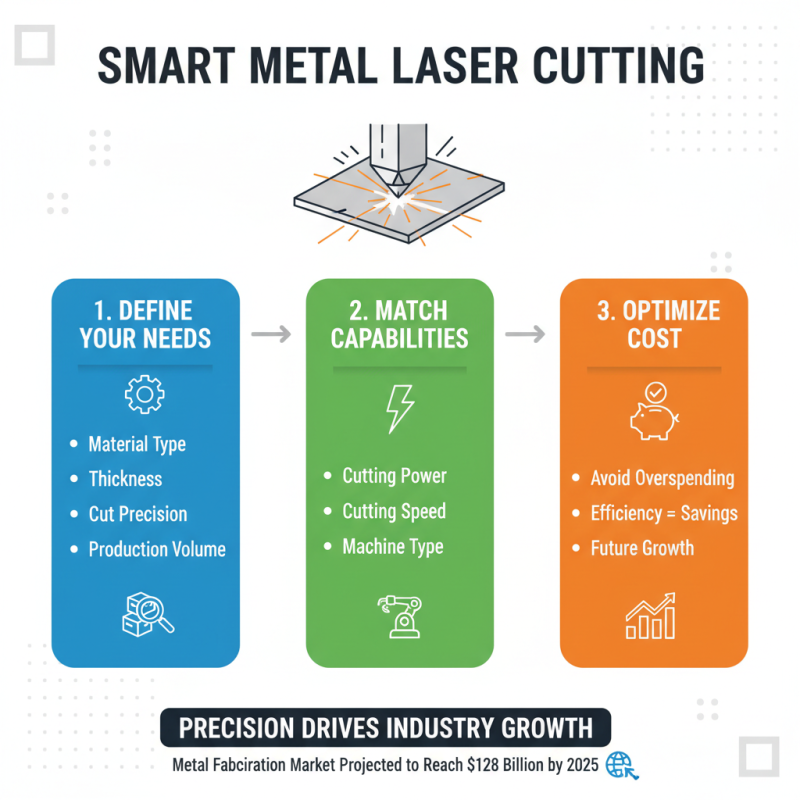

Understanding Your Metal Cutting Needs

When choosing a metal laser cutting service, it’s crucial to understand your specific needs first. Different projects require different cutting powers, speeds, and thickness levels. The demand for precise cuts has surged, with the metal fabrication industry projected to reach $128 billion by 2025. This illustrates how vital it is to identify your requirements to avoid overspending on capabilities you don't need.

Consider the types of metals involved in your project. Laser cutting can process materials like stainless steel, aluminum, and carbon steel, each with unique attributes. For instance, cutting aluminum requires a different focus than stainless steel. Reports suggest that precision is vital; companies experience a 30% drop in accuracy when using inappropriate settings. Evaluating the thickness of your materials is also key. Not every service can handle thick metals or will boast decent finish quality on intricate details.

Evaluate how you want your final product to look and function. Many companies often overlook that cutting speed and quality can conflict with each other. A faster cut might save time but can lead to edge roughness. It's not unusual to see a trade-off between efficiency and quality. Understanding your project’s complexity helps in choosing a service that balances these factors effectively.

Assessing the Capabilities of Laser Cutting Services

When selecting a metal laser cutting service, understanding their capabilities is crucial. A service with advanced technology can enhance precision. According to a report by the Laser Institute of America, the global laser cutting market grew by 5.6% in 2021. This growth implies that many companies are investing in cutting-edge machinery. Advanced systems often offer higher speed and better accuracy, which are critical for manufacturing needs.

Evaluating their equipment specifications is essential. A service should provide details on their laser types, power levels, and cutting thickness capabilities. For instance, fiber lasers are often preferred for their efficiency and speed. A laser cutting service should ideally be able to handle materials of varying thickness to accommodate diverse project requirements. Notably, a recent survey revealed that 72% of manufacturers prioritize cutting speed over cost. This indicates a shift towards performance-driven services.

It's also vital to assess quality control processes. This often reflects a company's commitment to customer satisfaction. Services that utilize real-time monitoring technology can ensure better results. However, many companies still rely on outdated methods, risking inconsistencies. Evaluating these aspects can guide you in making a well-informed decision. Sometimes, the best option isn’t the most expensive one, but rather the one that demonstrates a genuine understanding of your project’s needs.

Comparison of Key Factors in Metal Laser Cutting Services

Evaluating Quality and Precision in Metal Laser Cutting

When evaluating quality in metal laser cutting services, precision is key. Look for machines that utilize advanced technology for accurate cuts. These machines should have high resolution and fine tolerances. Poorly calibrated equipment can lead to jagged edges and wasted materials. Verify their cutting capabilities by asking for samples.

In addition to equipment, consider the expertise of the operators. Skilled hands can make a significant difference in finishing quality. Sometimes, even the best machines perform poorly without experienced personnel. Take a moment to review past projects or customer testimonials. It helps build trust in their ability to deliver.

Also, reflect on the materials being used. Different metals require specific laser settings. The right service should adapt to your needs, addressing any material-specific challenges. A one-size-fits-all solution may lead to inaccuracies. Engage in discussions about their processes and flexibility. Your project deserves focus on detail and quality assurance.

Comparing Costs and Service Options

When choosing a metal laser cutting service, comparing costs and service options is crucial. Each service provider may offer varying prices, and it’s important to understand what that price includes. You might find lower prices, but check for hidden fees. Does the cost cover setup and post-processing? These details can greatly influence the final expenditure.

Look at service options too. Some companies provide additional services, like design assistance or material sourcing. A higher price might bring added value, potentially saving time and effort later. Evaluate their turnaround times as well. Delays in production can disrupt schedules, leading to lost opportunities.

Not all services are created equal. Some may have cutting-edge technology, while others might use outdated methods. Visit their workshops if possible. Inspect the machinery and safety measures. You may find that a less expensive option doesn’t meet your quality requirements. Careful evaluation of both cost and service options can lead to better results. It’s essential to weigh the pros and cons carefully. Balancing budget and quality can sometimes feel daunting. This is where thorough research pays off.

Reading Reviews and Seeking Recommendations

When selecting a metal laser cutting service, reading reviews and seeking recommendations is crucial. Start by browsing online platforms where users share their experiences. Pay attention to details in the reviews. Look for comments on the quality of cuts, turnaround times, and customer support. Not every service will have perfect ratings. Take note of repeated concerns, as these can be red flags.

Ask for recommendations from industry peers or friends. Personal experiences can provide valuable insights. If someone had issues with a particular service, consider their input seriously. However, remember that individual experiences can vary. A service praised by one might not meet your specific needs.

Engage in discussions within relevant forums or social media groups. Ask questions and gauge the responses. This can help you form a clearer picture. Remember that a service might excel in certain areas but fall short in others. Be critical and reflective about the feedback you gather. This thoughtful approach can guide you toward making a more informed choice.

How to Choose the Best Metal Laser Cutting Service? - Reading Reviews and Seeking Recommendations

| Service Provider | Rating | Turnaround Time | Cost (per hour) | Customer Reviews |

|---|---|---|---|---|

| Provider A | 4.8 | 3 days | $150 | Excellent quality, timely delivery |

| Provider B | 4.5 | 5 days | $130 | Reliable, good customer service |

| Provider C | 4.3 | 4 days | $120 | Good for bulk orders |

| Provider D | 4.7 | 2 days | $160 | Fast service, high precision |

| Provider E | 4.6 | 6 days | $140 | Cost-effective solutions |

Related Posts

-

How to Effectively Utilize Metal Laser Cutting for Your Projects

-

Emerging Trends in Stainless Steel Laser Cutting Technologies at the 138th Canton Fair 2025 in China

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries