How to Choose the Best Laser Cut Parts for Your Project Needs

When embarking on a new project that requires precision and innovation, the choice of materials is crucial for achieving the desired outcome. Among the various options available, laser cut parts have gained immense popularity among designers and engineers alike. This cutting-edge technology allows for intricate designs and exact specifications, enabling creators to bring their visions to life with remarkable accuracy.

Choosing the best laser cut parts for your project needs involves considering several factors, including material type, thickness, and the method used for cutting. Each project is unique, and the right selection can significantly impact both functionality and aesthetics. By understanding the capabilities of different materials and the nuances of laser cutting, you can make informed decisions that enhance the overall quality of your work.

In this guide, we will explore essential criteria for selecting laser cut parts that align perfectly with your project's demands. Whether you're designing for industrial applications or artistic endeavors, knowing how to navigate your options will empower you to create impressive and effective solutions. Let’s delve into the vital aspects that will help you make the right choice for your next project.

Understanding Laser Cutting Technology and Its Applications

Laser cutting technology has become increasingly vital across various industries due to its precision and versatility. It utilizes focused laser beams to cut materials with exceptional accuracy, making it suitable for applications ranging from automotive components to intricate designs in electronics and medical devices. The technology is classified into types, such as fiber, CO2, and solid-state lasers, each tailored to specific materials and project requirements. Understanding these distinctions is essential for selecting the best laser-cut parts for any project.

The market for laser cutting machines has exhibited significant growth, influenced by the diverse functionalities of half-automatic and robotic systems. COVID-19 further accelerated this expansion as industries sought efficient manufacturing solutions to meet changing demands. As projects like the establishment of laser industrial bases in cities enhance production capabilities, the ongoing evolution of laser cutting technology promises to cater to emerging applications and materials in the future, ensuring businesses can adapt to new challenges and opportunities.

Understanding Laser Cutting Technology Applications

Key Factors in Selecting Materials for Laser Cut Parts

When selecting materials for laser-cut parts, several key factors come into play. First, the type of material significantly impacts the precision and quality of the cut. Common materials include metals, plastics, and wood, each requiring different laser settings and techniques. Understanding the characteristics of these materials, such as their thickness, density, and melting point, is crucial. For instance, while metals may require higher power and faster speeds, acrylic materials can be cut at lower settings, providing a clean edge without melting.

Another factor to consider is the intended application of the laser-cut parts. The functionality and durability requirements of the finished product will dictate material choice. For example, components used in aerospace applications must meet stringent strength and weight criteria, necessitating the use of specific alloys or composites. Additionally, surface finish and aesthetic considerations might influence the decision, particularly for parts that are visible or require secondary processing.

Ultimately, aligning material selection with the performance specifications and desired outcomes is essential to optimize the benefits of laser cutting technology.

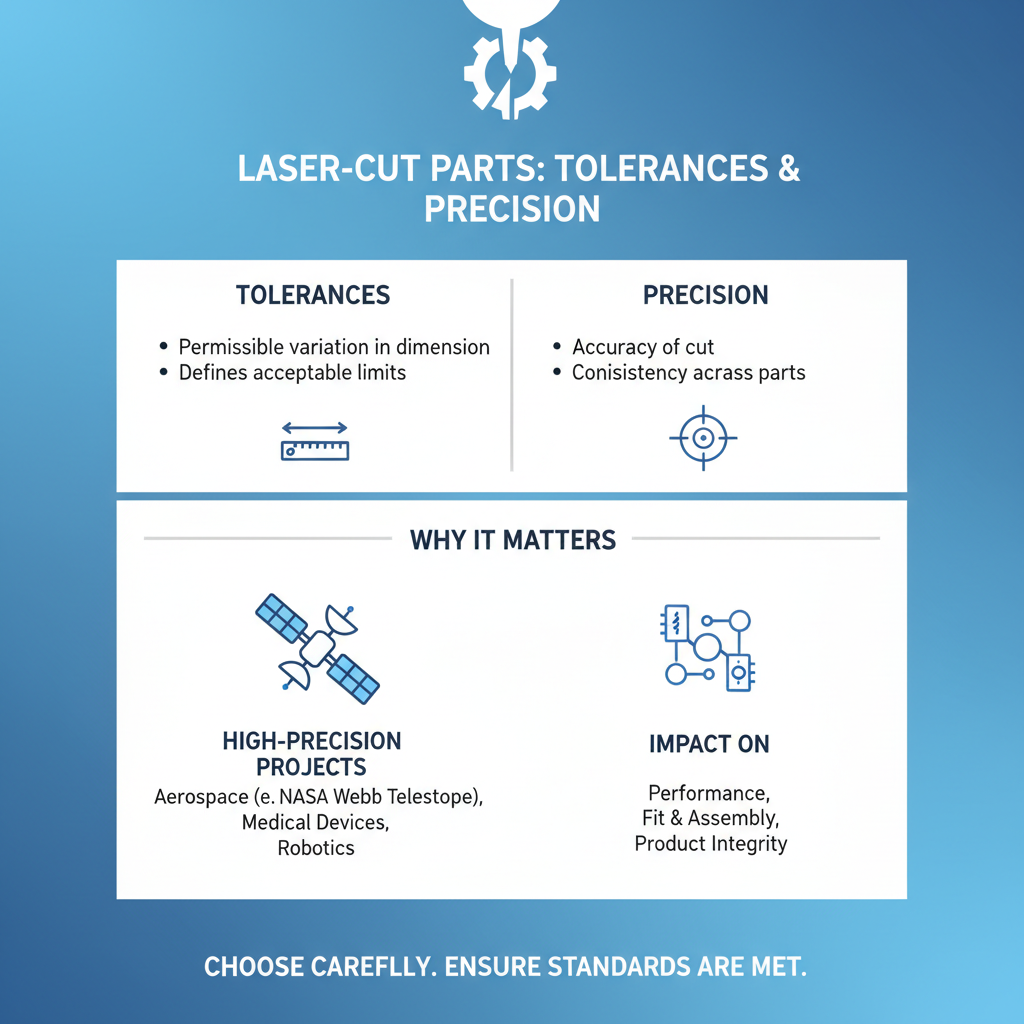

Evaluating Tolerances and Precision Requirements in Your Project

When selecting laser cut parts for your project, evaluating tolerances and precision requirements is crucial. Tolerances refer to the permissible limits of variation in a physical dimension. If your project demands high precision, such as in aerospace applications like NASA's Webb telescope, it's essential to ensure that the laser cut parts meet specific standards closely. Precision in cutting can significantly affect the overall performance and integrity of the final product.

Tips: Always specify your tolerances when requesting quotes for laser cutting services. This ensures that the manufacturer understands the exact requirements, thereby reducing the chances of errors. Additionally, consider using high-throughput methods for precision assessments, similar to UAV image-based techniques employed in agricultural studies. These innovative approaches can provide consistent quality benchmarks and enhance the accuracy of your project.

It's also vital to stay informed about the latest developments in technology that impact your project's requirements. For example, advancements in software engineering and data analysis can streamline the process of identifying needed tolerances and improve precision, a practice that is increasingly relevant in various fields, including biomedical research. Adopting these strategies will help you achieve the necessary accuracy for your project.

Cost Analysis: Balancing Budget and Quality for Laser Cut Parts

When undertaking a project that requires laser cut parts, it's essential to balance your budget with the quality of materials you need. Understanding the cost analysis of laser cutting services can guide you in making informed decisions that will enhance your project's outcome without breaking the bank. While it might be tempting to choose cheaper options, these often come with compromises in quality, durability, or precision that could affect the performance of your end product.

Tips: Always request samples from your supplier to evaluate the quality before placing a large order. Additionally, consider the complexity of your design. Simplifying your designs can significantly reduce costs while maintaining structural integrity. Comparing multiple quotes can also help you find the best deal without sacrificing quality.

Another important aspect is the material selection; different materials have varying costs associated with their laser cutting. Investigate alternatives that suit your project's needs but are easier on your budget. Remember, investing a little more upfront in high-quality parts may save you money in the long run by reducing the need for replacements or repairs.

Sustainability Considerations in Choosing Laser Cut Materials

When selecting laser cut parts for your project, sustainability should be a key consideration in material choice. The growing emphasis on eco-friendly manufacturing has led to innovations in laser technology that minimize waste and energy consumption. Advanced lasers, particularly those utilizing ultrashort bursts of light, are able to create precision parts with remarkable efficiency, significantly reducing excess material and offering opportunities for recycling. By choosing sustainable materials and processes, manufacturers can not only meet environmental standards but also appeal to a market that increasingly values sustainability.

The latest trends in laser technology and industrial machine design emphasize modularity and intelligent systems, which contribute to waste reduction and efficiency. Companies are increasingly adopting these innovations to enhance their manufacturing processes while maintaining a commitment to environmental responsibility. As the landscape of industrial manufacturing evolves, understanding these trends will be crucial for businesses aiming to stay competitive and eco-conscious. By aligning project needs with sustainable practices and cutting-edge technologies, manufacturers can achieve both operational excellence and a positive impact on the planet.

Related Posts

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023

-

What is Laser Cutting Service and How it Revolutionizes Modern Manufacturing