How to Choose the Best CNC Cutting Methods for Your Project Needs

In the ever-evolving landscape of manufacturing, selecting the most suitable CNC cutting method for your project needs can be a daunting task. As industry expert Dr. Emily Carter once noted, “The right CNC cutting technique can dramatically enhance precision and efficiency, ultimately leading to a superior final product.” This wisdom speaks volumes about the importance of understanding the different CNC cutting options available, as well as their respective advantages and limitations.

CNC cutting encompasses a wide range of techniques, from laser cutting and waterjet cutting to plasma cutting and traditional milling. Each method has its unique strengths, and the choice of technique can significantly impact the outcome of a project. Factors such as the material being used, the required tolerances, production volume, and budget constraints all play crucial roles in determining which CNC cutting method will be the best fit.

As we delve deeper into this topic, we will explore key considerations that should guide your decision-making process while highlighting the latest advancements and innovations in CNC cutting technology. Understanding these essential aspects will empower you to make informed choices that align with your project goals and ultimately lead to successful outcomes.

Factors to Consider When Selecting CNC Cutting Methods for Projects

When selecting CNC cutting methods for your project, several key factors should be taken into account to ensure optimal results. First and foremost is the material you intend to work with. Different materials, such as metals, plastics, and composites, require specific cutting techniques. For instance, harder materials like steel may necessitate more robust cutting processes like laser or plasma cutting, while softer materials might be efficiently handled by waterjet or router cutting methods.

Another critical factor to consider is the desired precision and finish quality. The tolerances required for your project can greatly influence your choice of cutting method. For projects that demand high precision and intricate designs, methods like laser cutting offer excellent detail and minimal kerf width. Additionally, the thickness of the material can also dictate the best cutting option; thicker materials may require more powerful cutting methods, while thinner materials can be processed with less energy-intensive techniques. By carefully evaluating these factors, you can select the most suitable CNC cutting method that aligns with your project specifications and goals.

How to Choose the Best CNC Cutting Methods for Your Project Needs

| CNC Cutting Method | Material Compatibility | Thickness Range (mm) | Precision (mm) | Production Speed (m/min) | Cost Efficiency |

|---|---|---|---|---|---|

| Laser Cutting | Metals, Plastics, Wood | 0.1 - 20 | 0.1 - 0.5 | 10 - 30 | High |

| Waterjet Cutting | Metals, Stone, Glass | 1 - 200 | 0.3 - 1.0 | 5 - 15 | Moderate |

| Plasma Cutting | Metals | 1 - 50 | 0.5 - 2.0 | 8 - 25 | Low |

| Router Cutting | Wood, Plastics | 1 - 50 | 0.2 - 0.7 | 12 - 40 | High |

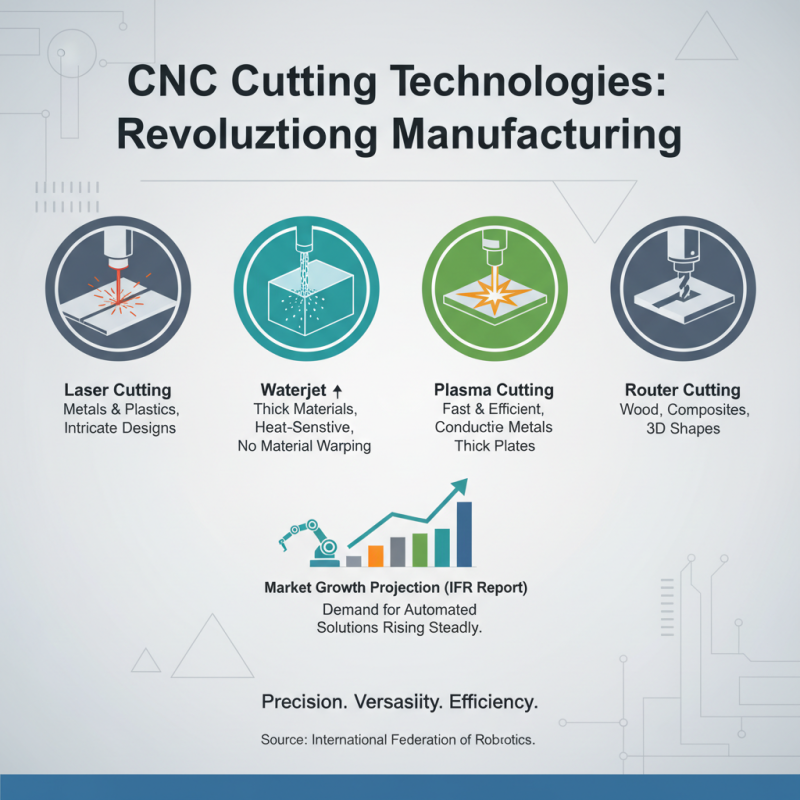

Overview of CNC Cutting Technologies: Types and Applications

CNC cutting technologies have revolutionized manufacturing across various industries by providing precision, versatility, and efficiency. The most common CNC cutting methods include laser cutting, waterjet cutting, plasma cutting, and router cutting. Each technique has its unique applications and advantages. For instance, laser cutting is known for its high precision and is ideal for materials like metals and plastics, whereas waterjet cutting is excellent for thicker materials and those sensitive to high temperatures. According to a report by the International Federation of Robotics, the CNC cutting equipment market is projected to grow steadily, emphasizing the increasing demand for automated cutting solutions.

When choosing the best CNC cutting method for your project, consider material compatibility, thickness, and the desired finish. For intricate designs, laser cutting might be the preferred option, while for thicker materials where heat distortion is a concern, waterjet cutting could be more suitable. Tip: Always conduct a cost-benefit analysis to determine which method aligns best with your budget and project timelines.

Additionally, staying updated with advancements in CNC technology can provide insights into optimizing your production processes. For example, peer-reviewed studies have shown that integrating automation with CNC cutting can enhance productivity by up to 30%, minimizing material waste and reducing labor costs. Tip: Invest in training for your team to fully leverage the capabilities of your chosen CNC cutting method, ensuring that they are proficient in utilizing the equipment effectively and efficiently.

Comparative Analysis of Cost-Effectiveness in CNC Cutting Methods

In the realm of CNC cutting methods, cost-effectiveness plays a pivotal role in project selection. Various techniques, such as laser cutting, waterjet cutting, and plasma cutting, each have distinct advantages and limitations, influencing their overall cost. For instance, laser cutting is revered for its precision and ability to handle intricate designs, making it an ideal choice for projects where detail is crucial. However, the operational costs can escalate with thicker materials, potentially impacting the project's budget.

On the other hand, waterjet cutting boasts versatility, allowing it to work with a wider array of materials without thermal distortion. This method’s capability to produce clean cuts at relatively moderate costs can be appealing, particularly for low to medium production volumes. Plasma cutting, while generally more economical in terms of setup and operation, may not always deliver the quality required for precision work, which could lead to additional finishing processes that may negate initial cost savings. By conducting a detailed comparative analysis of these CNC cutting methods, project managers can ascertain which technique best aligns with their budget and quality requirements, ensuring that they achieve optimal results without unnecessary expenditure.

Material Compatibility: Choosing CNC Cutting for Different Materials

When selecting CNC cutting methods, material compatibility plays a pivotal role in achieving optimal results. Different materials—such as metals, plastics, wood, and composites—require specific CNC techniques to ensure effective cutting and shaping. According to a 2022 report by the International Journal of Advanced Manufacturing Technology, around 40% of cutting inefficiencies stem from using inappropriate methods for specific materials. For instance, while laser cutting excels with thin metals and plastics due to its precision and speed, plasma cutting is often preferred for thicker metal sheets due to its ability to handle higher material thickness without significant heat distortion.

Moreover, understanding the thermal properties and mechanical characteristics of materials can further inform the choice of CNC cutting method. A study published by the Society of Manufacturing Engineers indicates that materials with high thermal conductivity, like aluminum, can benefit from waterjet cutting, which minimizes thermal damage and maintains structural integrity. In contrast, materials such as carbon fiber or fiberglass require specialized CNC routers to prevent delamination and ensure clean edges. Recognizing these intricacies not only enhances efficiency but also mitigates the risk of project failures associated with material incompatibility.

Precision and Tolerances: Evaluating CNC Cutting Techniques for Accuracy

When evaluating CNC cutting techniques for accuracy, precision is paramount. Different CNC cutting methods such as laser cutting, waterjet cutting, and plasma cutting offer varying levels of precision suited to distinct project requirements. For instance, laser cutting boasts a remarkable tolerance of ±0.005 inches, making it ideal for applications that demand intricate design work and fine detailing, especially in industries like aerospace and electronics. Meanwhile, waterjet cutting provides excellent precision with a tolerance of ±0.010 inches, making it effective for cutting thicker materials without affecting the structural integrity.

**Tips:** When selecting a CNC cutting method, consider the material you are working with and its thickness. Thicker materials may benefit from waterjet technology due to its ability to handle and restore integrity better than other methods. Additionally, for projects requiring tight tolerances, laser cutting would be the most suitable option, despite potentially higher operational costs.

Furthermore, understanding the finish quality desired for your project is crucial. CNC methods can vary significantly in terms of the surface finish they produce. Reports indicate that laser cutting generally results in a cleaner edge, which often requires less post-processing. Thus, weighing the importance of precision and required post-processing can guide you in choosing the most effective CNC cutting technique for your specific project needs.

Comparison of CNC Cutting Methods by Precision and Tolerance

This chart illustrates the precision of various CNC cutting methods relevant to project needs, highlighting the accuracy typically achieved with each technique. Laser cutting and CNC milling show the highest precision, while plasma cutting falls behind.

Related Posts

-

What is the Advantage of Using a CNC Router for Your Business

-

2025 Top 10 CNC Machining Trends Transforming Manufacturing Industry

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects

-

Exploring the Future of Manufacturing with Laser Table Technology

-

2025 How to Master Metal Engraving Techniques for Perfect Results

-

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025