How to Choose the Best Laser Table for Your Cutting Needs

Selecting the ideal laser table for your cutting requirements can significantly affect the quality and efficiency of your projects. According to Dr. Emily Roberts, a leading expert in laser technology, “The right laser table not only enhances precision but also improves workflow and productivity.” With a myriad of options available in the market, understanding the key features and capabilities of different laser tables is crucial for both novice users and seasoned professionals.

In the ever-evolving world of laser cutting, choosing the perfect laser table involves evaluating factors such as cutting area, power, and the material compatibility. Users must consider their specific cutting needs and the types of projects they undertake. From intricate designs to large-scale industrial applications, the appropriate laser table can make a significant difference in achieving desired outcomes.

As the demand for advanced cutting technology grows, making an informed choice about laser tables becomes even more critical. This guide aims to simplify the decision-making process by highlighting essential criteria to consider when selecting a laser table, ensuring that your investments lead to optimal performance and precision in your cutting tasks.

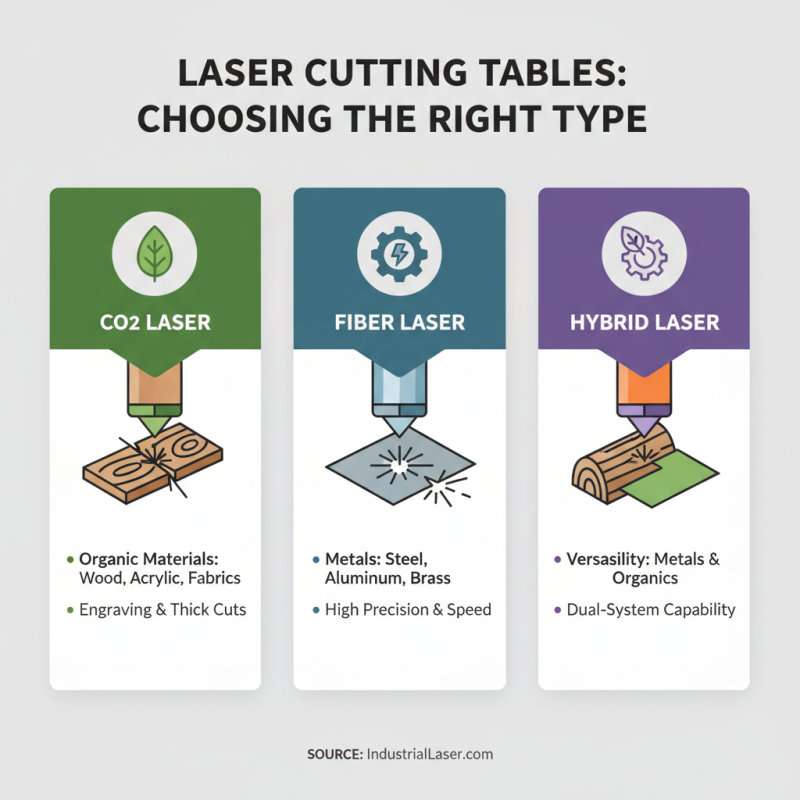

Understanding Different Types of Laser Cutting Tables

When considering the right laser cutting table for your needs, it’s essential to understand the different types available. The main categories include CO2 laser cutting tables, fiber laser cutting tables, and hybrid models. Each type comes with distinct features suitable for various materials and cutting techniques. CO2 lasers are excellent for organic materials like wood and acrylic, while fiber lasers excel in cutting metals due to their high energy efficiency and precision.

**Tips:** When selecting a table, evaluate the materials you primarily plan to cut. Knowing whether you’ll be working with thick metals or delicate materials like fabrics can guide your choice. Additionally, consider the size of the workspace and the maximum cutting area required for your projects, ensuring that the table you select can accommodate your largest workpieces.

Another important factor to consider is the table's power capacity. Higher wattage machines offer faster cutting speeds and the ability to handle thicker materials. Ensure the laser cutting table aligns with your production needs and can grow with your business, allowing for future upgrades or expansions. Always check compatibility with various software and ease of use, as a user-friendly interface can greatly enhance productivity.

Key Factors to Consider When Selecting a Laser Table

When selecting a laser table, it's crucial to consider several key factors to ensure it meets your cutting needs effectively. First and foremost, the size of the working area is essential. Depending on the materials you plan to cut and the dimensions of your projects, the size of the laser table should accommodate your needs. A larger working area provides more flexibility for larger designs, while a smaller table may be more suitable for compact projects.

Another critical factor is the power of the laser. The wattage directly influences the types of materials you can cut and the speed at which you can do so. Higher wattage machines can handle thicker materials and provide faster cutting speeds, while lower wattage options might be sufficient for thinner materials. Additionally, consider the type of laser technology used, as CO2 and fiber lasers have different strengths and applications. Understanding your materials and the application will guide you in choosing the right power level for your projects.

Lastly, ease of use and software compatibility play vital roles in selecting a laser table. Look for a machine that offers user-friendly software and good customer support, as this can significantly enhance your cutting experience. Additionally, check for features such as adjustable settings, safety mechanisms, and maintenance requirements to ensure the table suits your operational needs. Each of these factors contributes to a more efficient and effective laser cutting process.

How to Choose the Best Laser Table for Your Cutting Needs - Key Factors to Consider When Selecting a Laser Table

| Feature | Description | Importance Level |

|---|---|---|

| Laser Power | Measured in watts, determines cutting speed and material thickness capability. | High |

| Cutting Area Size | Dimensions of the table, affecting the maximum workpiece size. | Medium |

| Material Compatibility | Types of materials the laser can cut or engrave, such as wood, acrylic, and metals. | High |

| Cooling System | Type of cooling, either air or water-cooled, affecting performance and maintenance. | Medium |

| Software Compatibility | Types of design software supported for easier operations and design settings. | High |

| Price | Total cost including setup, installation, and maintenance. | High |

| Safety Features | Includes shields, emergency stops, and ventilation systems for safe operation. | High |

Evaluating Power and Speed Requirements for Your Projects

When selecting the ideal laser table for your cutting projects, understanding the power and speed requirements is crucial. Laser tables are equipped with different wattage levels, which directly influence their cutting capabilities. Higher wattage lasers can effortlessly cut through thicker materials, making them suitable for industrial applications. Conversely, for lighter projects such as fine engraving or cutting thin sheets, a lower wattage may suffice, providing greater precision while reducing operational costs.

In addition to power, speed is another vital factor to consider. The cutting speed of a laser table determines how quickly the machine can process materials. Faster speeds can enhance productivity but may compromise cutting quality, particularly on intricate designs. Hence, it’s important to achieve a balance between speed and precision based on the specific requirements of your projects. For those working with more delicate materials or intricate patterns, a slower speed might be beneficial to ensure clean and accurate cuts. Evaluating these aspects will help you select the laser table that best aligns with your intended applications and production goals.

Comparing Material Compatibility with Laser Cutting Tables

When selecting a laser cutting table, one of the most vital aspects to consider is its compatibility with various materials. Different laser tables utilize distinct technologies and power levels, which significantly impact their ability to cut through specific materials effectively. According to a report by the Laser Institute of America, CO2 lasers are particularly adept at cutting non-metal materials such as wood, acrylic, and certain plastics, while fiber lasers excel in processing metals like steel and aluminum. Understanding the material compatibility can help users determine the best technology suited to their specific needs.

Furthermore, material thickness is a critical factor when evaluating laser cutting tables. Research from the International Journal of Advanced Manufacturing Technology highlights that laser power, measured in watts, plays a pivotal role in determining the maximum material thickness a laser can cut efficiently. For instance, a 100-watt CO2 laser can typically handle materials up to 1/4 inch thick, while higher wattage systems can accommodate thicker profiles. By assessing both the types of materials and their respective thicknesses, users can make informed decisions that align with their cutting requirements, ultimately enhancing productivity and output quality.

Material Compatibility with Laser Cutting Tables

Budgeting for Your Laser Cutting Table Investment

When investing in a laser cutting table, budgeting is a critical aspect that can significantly influence your overall satisfaction and financial health. First, it's important to assess your specific cutting needs, including the types of materials you will work with and the complexity of projects you anticipate. This understanding will help you determine the features that are essential for your operations. Creating a detailed list of necessary specifications, such as power output, table size, and additional functionalities, will guide you in setting a realistic budget.

Additionally, consider the long-term costs associated with the laser table. Beyond the initial purchase price, factor in maintenance, operational costs, and potential upgrades or accessories you may need in the future. It's vital to strike a balance between investing in a quality machine that meets your cutting needs and ensuring that you do not overextend your budget. Taking the time to analyze both initial and ongoing expenses will help you make an informed decision that aligns with your financial capabilities and cutting requirements.

Related Posts

-

Exploring the Future of Manufacturing with Laser Table Technology

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

How to Choose the Best Laser Cut Parts for Your Project Needs

-

Unlocking Creativity: How Laser Cutting and Engraving Transforms DIY Projects