Best Steel Laser Cutting Techniques for Precision and Efficiency?

In the world of manufacturing, precision matters. Steel laser cutting has emerged as a vital technique for achieving high efficiency and accuracy. This method allows for intricate designs and reduced material wastage. It revolutionizes various industries, including automotive and aerospace.

However, not all steel laser cutting approaches yield the same outcomes. Some techniques may overlook critical factors, leading to suboptimal results. Choosing the right configuration and technology is essential yet challenging. The intricacies of steel types and thicknesses add another layer of complexity.

With advancements in technology, the available methods for steel laser cutting continue to evolve. Still, companies must carefully evaluate their processes. Balancing speed and precision can be tricky. Reflecting on these aspects ensures that manufacturers can maximize productivity while maintaining quality. Embracing the best practices in steel laser cutting ultimately promotes growth and innovation.

Overview of Steel Laser Cutting Techniques

Steel laser cutting techniques have evolved significantly in recent years. High-power fiber lasers are popular for their efficiency. These lasers produce a high-quality cut with minimal waste, allowing for faster production. However, they require precise calibration and regular maintenance to perform optimally.

CO2 lasers are another option. They are effective for cutting thick steel. Their ability to handle complex designs is impressive. But, they need more energy and can be slower in some cases. Users might notice a slight difference in the edge quality compared to fiber lasers.

Understanding the different techniques is crucial. Each method has its strengths and weaknesses. The choice often depends on the project requirements. It's vital to reflect on the specific needs of production. Balancing speed and precision is sometimes challenging. Nevertheless, the right technique can lead to remarkable results.

Factors Influencing Precision in Laser Cutting

Precision in laser cutting is influenced by several key factors. Material type plays a crucial role. Different steels absorb laser energy differently. Some materials may require specific settings to achieve optimal results. If the settings are mismatched, it could lead to poor cuts.

Another significant factor is the thickness of the steel. Thicker materials present challenges. They need more power and slower cutting speeds. However, excessive power can cause heat distortion. This might result in warping or a rough edge finish. Proper calibration is essential to find the right balance.

The skill level of the operator also matters. Experience can significantly affect the outcome. Novice operators might not adjust settings correctly. This could lead to wasted material and time. Regular training and practice are vital for efficiency. Inconsistent techniques can create variability in results, prompting a need for reflection and improvement.

Best Steel Laser Cutting Techniques for Precision and Efficiency

| Technique | Precision Level | Efficiency Rating | Common Applications | Key Factors Influencing Precision |

|---|---|---|---|---|

| Fiber Laser Cutting | High | 90% | Sheet Metal Fabrication | Focus Length, Power Settings |

| CO2 Laser Cutting | Medium | 85% | Industrial Applications | Gas Pressure, Beam Mode |

| Nd:YAG Laser Cutting | Medium to High | 80% | Metal Cutting, Engraving | Pulse Duration, Energy Output |

| Plasma Laser Cutting | Medium | 75% | Thick Materials | Gas Type, Cutting Speed |

Efficiency Considerations in Laser Cutting Processes

Efficiency is crucial in steel laser cutting processes. The right technique can drastically improve productivity. Cutting speed, power settings, and material thickness all contribute to efficiency. It’s vital to assess these elements for optimal performance.

Tips for Laser Cutting Efficiency: Choose the right power settings based on material thickness. If the power is too low, cutting can become slow and imprecise. Conversely, excessive power can lead to damage. Regularly check the focus of the laser beam. A misaligned beam can reduce cutting quality, resulting in waste.

Another consideration is the maintenance of the cutting machine. Regular maintenance ensures that the equipment runs smoothly. However, delays in maintenance can lead to downtime. Implement a routine schedule for checks. This proactive approach can save time and costs in the long run. Even small adjustments can lead to significant improvements in efficiency.

Assessing the laser cutting layout can also enhance workflows. A cluttered setup can slow down the process. Organize workspaces to facilitate seamless operation. Sometimes, a minor organizational tweak makes a substantial difference. Balancing efficiency with precision requires ongoing evaluation of processes.

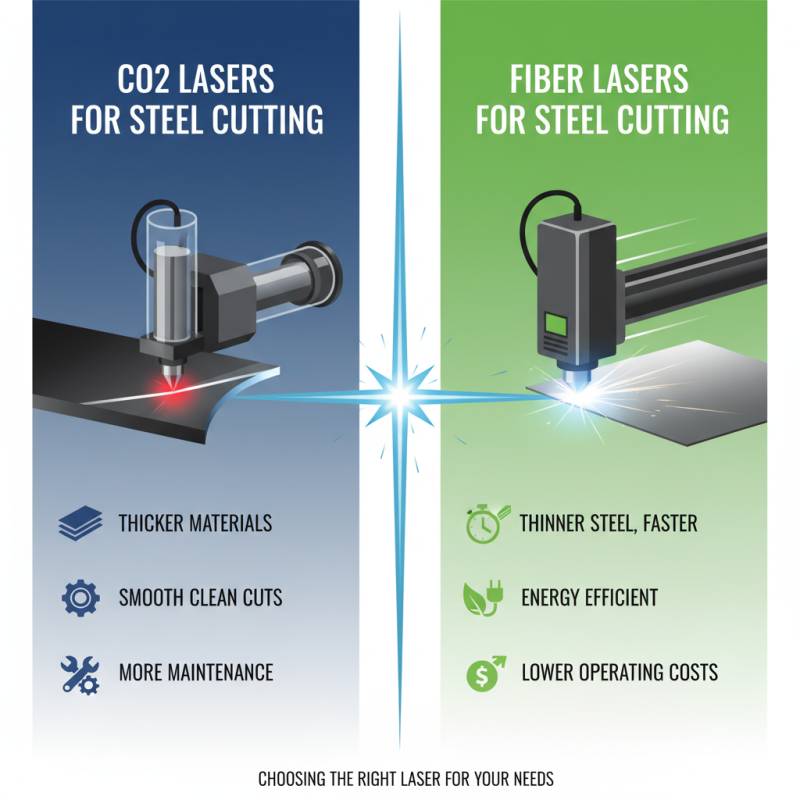

Comparison of Different Laser Types for Steel Cutting

When cutting steel, the choice of laser type plays a critical role. CO2 lasers are widely used due to their effectiveness in thicker materials. They provide a smooth cut and can handle intricate designs well. However, they often require more maintenance. Fiber lasers are becoming popular. They are efficient and faster, especially for thinner steel. Fiber lasers consume less energy, which can lower operating costs.

Yet, each laser type has its challenges. CO2 lasers can struggle with speed on thinner metals, leading to heat issues. Meanwhile, fiber lasers might not perform as effectively on very thick materials. This can lead to burn marks or edge damage. Understanding the limitations helps in making informed decisions. For instance, picking a laser type based on material thickness can enhance precision.

In practice, operators might need to adjust settings frequently. An iterative approach often yields the best results. It’s crucial to test various settings on scrap pieces. This hands-on method reveals performance nuances. Experimentation offers deeper insights into which laser suits specific tasks. Balancing precision and efficiency requires continual reflection and adaptation.

Future Trends in Steel Laser Cutting Technology

The future of steel laser cutting technology is bright and full of promise. As industries seek precision and efficiency, new trends are emerging. Advanced laser systems now offer improved power and speed. These systems enhance productivity while reducing operational costs.

Automation plays a key role in this evolution. Innovative software solutions enable seamless integration with existing workflows. However, this transition can pose challenges. Not all operators are trained for automated systems. A learning curve exists, and it must be addressed.

Tips: Invest in training programs for your staff. Familiarity with the latest technologies can greatly improve efficiency. Regular maintenance of lasers is crucial. Neglecting this can lead to costly downtime. As technology advances, staying updated is essential for competitive edge. Embrace change, but recognize the need for careful implementation. Adaptation is key to success in laser cutting.

Best Steel Laser Cutting Techniques for Precision and Efficiency

Related Posts

-

Why Steel Laser Cutting is Essential for Precision Manufacturing in 2023

-

Unlock Unlimited Possibilities with Custom Laser Cutting for Your Unique Projects

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

Unlocking the Future of Design: How Custom Laser Cutting is Revolutionizing Creative Industries

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

How to Choose the Best Laser Cut Parts for Your Project Needs