2026 Best CNC Machining Parts for Precision Engineering and Manufacturing?

In the rapidly evolving world of precision engineering, CNC machining parts play a vital role. Expert Mark Thompson, a leader in CNC technology, emphasizes, "Precision is not just a goal; it's a necessity." This statement underscores the importance of high-quality CNC machining parts in achieving outstanding manufacturing results.

CNC machining parts are essential in diverse industries, from aerospace to automotive. These components require fine tolerances and accurate dimensions. However, achieving the ideal balance of quality and cost can be challenging. Companies often struggle to select the right materials and processes, leading to potential inefficiencies.

Moreover, while many manufacturers focus on speed, neglecting precision can lead to waste. The complexity of design might overwhelm smaller businesses. Each piece must be crafted with care, ensuring functional integrity. With ongoing advancements, CNC machining parts will continue to shape the future of manufacturing. Companies must adapt or risk falling behind.

Overview of CNC Machining and Its Importance in Precision Engineering

CNC machining plays a critical role in precision engineering. This technology allows for high accuracy in manufacturing parts across various industries. With a focus on automation, CNC machines can produce complex designs that traditional methods struggle to achieve. The consistency of CNC machining ensures that each part produced meets strict quality standards.

However, not all CNC machining processes are flawless. There are challenges in maintaining precision. Variations in material quality can lead to production errors. Sometimes the programming of the machines can result in unexpected outcomes. Operators must closely monitor the machines, as even small mistakes can lead to waste and additional costs.

Understanding the importance of CNC machining requires acknowledging these imperfections. Continuous improvement is vital. Regular maintenance of machines can reduce issues. Ongoing training for operators ensures they can manage the complexities effectively. CNC machining is a powerful tool, but it requires diligence to achieve its full potential in precision engineering.

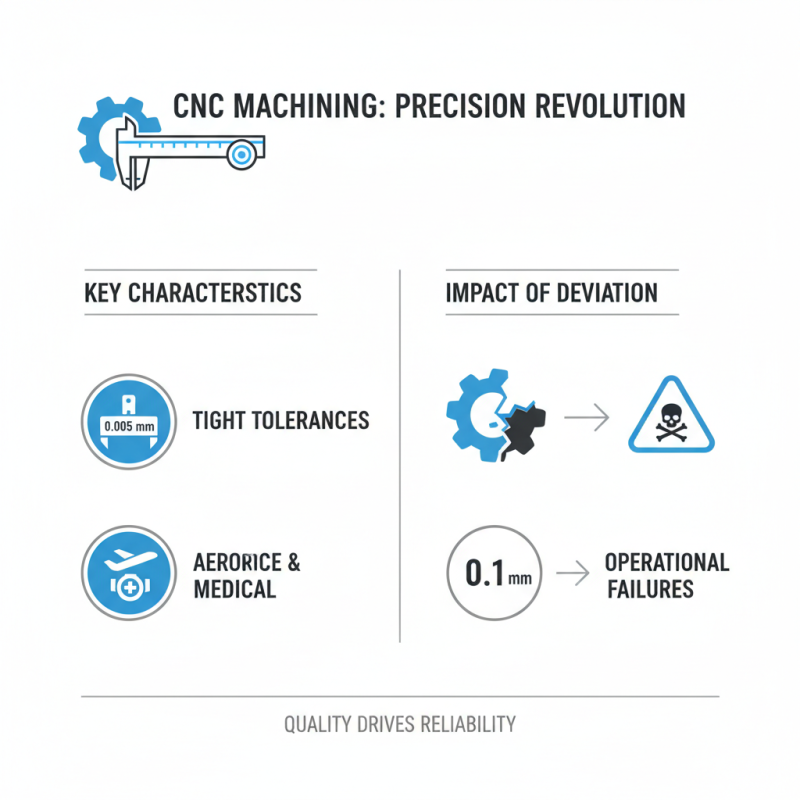

Key Features of High-Quality CNC Machined Parts for Manufacturing

CNC machining has revolutionized precision engineering. Quality machined parts demand rigorous standards. High-quality CNC parts often feature tight tolerances within 0.005 mm. This precision is crucial in industries like aerospace and medical devices. Reports suggest that a mere 0.1 mm deviation can lead to significant operational failures.

Material selection is another critical aspect. Parts made from durable materials like aluminum or titanium enhance final product performance. Consider that titanium offers excellent strength-to-weight ratios. However, difficulties in machining can arise. This complexity may lead to increased production costs and time.

Tips: Always verify the supplier's quality certifications. This step ensures the consistency of machined parts. Regular inspections during production can help catch issues early. Remember, even minor flaws can result in enormous costs down the line. Finding the perfect balance between speed and precision is essential for successful manufacturing. Pay attention to the machining process; it should maintain high efficiency without sacrificing quality.

Top Materials Used in CNC Machining for Optimal Performance

CNC machining has transformed precision engineering significantly. The choice of materials plays a crucial role in achieving optimal performance. Commonly used materials include aluminum, steel, and plastic.

Aluminum is lightweight and offers good machinability. Steel, on the other hand, provides durability and strength. Plastic is versatile and can be molded into complex shapes.

When selecting materials, it's important to consider specific project requirements. Not all materials perform the same under various conditions. For instance, some plastics might deform under heat. Steel is robust but can be challenging to machine. This often leads to unexpected challenges during the manufacturing process.

Choosing the right material often involves trade-offs. A lightweight part may not be as strong. Similarly, a strong part may weigh more than desired. This balancing act requires careful thought and planning. The materials chosen can ultimately dictate the success of a project. Understanding their properties is essential for every engineer.

Innovative CNC Machining Technologies Shaping the Future of Manufacturing

Innovative CNC machining technologies are transforming the landscape of manufacturing. Advanced software now enables precise programming for complex geometries. This reduces errors and increases production efficiency significantly. Automation plays a key role here. Robotic arms enhance speed and reduce labor costs. They can work tirelessly, producing consistent results.

However, challenges remain. Not all manufacturers fully utilize CNC capabilities. Some stick to outdated methods, missing out on potential gains. The learning curve for new technology can be steep. It’s important for teams to invest time in training. Additionally, not every industry has access to the latest equipment. This digital divide can hinder progress.

Collaboration is crucial. Engineers and machinists need to work closely to innovate. Sharing insights can lead to breakthroughs in design and functionality. The path forward isn’t without bumps. As the industry evolves, keeping pace with technology is essential. Embracing change will shape the future of precision engineering.

2026 Best CNC Machining Parts for Precision Engineering and Manufacturing

| Part Name | Material | Tolerance | Surface Finish | Applications |

|---|---|---|---|---|

| Precision Gear | Aluminum 6061 | ±0.01 mm | Anodized | Automotive, Aerospace |

| Mounting Bracket | Stainless Steel 304 | ±0.02 mm | Polished | Electronics, Machinery |

| Valve Body | Brass | ±0.03 mm | Natural | Plumbing, HVAC |

| Custom Housing | Polymer | ±0.05 mm | Textured | Consumer Products |

| Heat Sink | Aluminum 6063 | ±0.01 mm | Machined Finish | Electronics, Cooling Systems |

Applications of CNC Machined Parts in Various Industries

CNC machining is critical across diverse industries. Automotive, aerospace, and medical sectors heavily rely on precision-engineered parts. In 2022, the global CNC machining market was valued at approximately $63 billion and is expected to grow steadily. This growth highlights the increasing demand for high-quality components.

In the automotive industry, CNC machined parts ensure safety and performance. Components like engine blocks and brackets require precision for optimal functionality. Reports indicate a rise in demand for lightweight materials, which CNC machining can effectively produce. Aerospace applications also benefit from lightweight and durable components. Turbine blades and structural parts are often CNC machined to meet strict safety standards while minimizing weight.

The medical field utilizes CNC machining for surgical instruments and implants. These parts must meet high-quality standards and tight tolerances. Reports show that around 45% of medical companies consider CNC machining essential for new product development. While the technology offers flexibility, there are challenges. Variances in material properties and production processes can lead to quality discrepancies. Continuous improvement in techniques and equipment is necessary to meet evolving standards. Understanding and addressing these challenges is crucial for staying competitive.

Related Posts

-

2025 Top 10 CNC Machining Trends Transforming Manufacturing Industry

-

What is the Advantage of Using a CNC Router for Your Business

-

How to Choose the Best CNC Cutting Methods for Your Project Needs

-

The Ultimate Guide to Choosing the Best CNC Engraver for Your Projects

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

Maximizing Your Workspace Efficiency with the Right Cutting Table for Your Crafting Needs