2026 Top Laser CNC Machines What You Need to Know?

In the rapidly evolving manufacturing sector, laser CNC machines are gaining significant attention. According to a report by MarketsandMarkets, the global laser CNC market is projected to grow at a CAGR of 6.7% from 2021 to 2026. This growth indicates a robust demand from various industries, including automotive, aerospace, and medical.

Expert John Carter, a leading figure in laser technology, emphasizes the transition: "Laser CNC machines are transforming precision engineering." This statement captures the essence of how these machines enhance production efficiency and accuracy. With their ability to cut, engrave, and mark a variety of materials, laser CNC machines are crucial for businesses striving for innovation. However, the technology is not without challenges. Many users face a steep learning curve and require substantial initial investment.

As companies consider integrating laser CNC systems, they must weigh the long-term benefits against the upfront costs. The balance between operational efficiency and capital expenditure remains a significant point for reflection. Understanding these dynamics is essential for anyone looking to navigate the complexities of laser CNC technology.

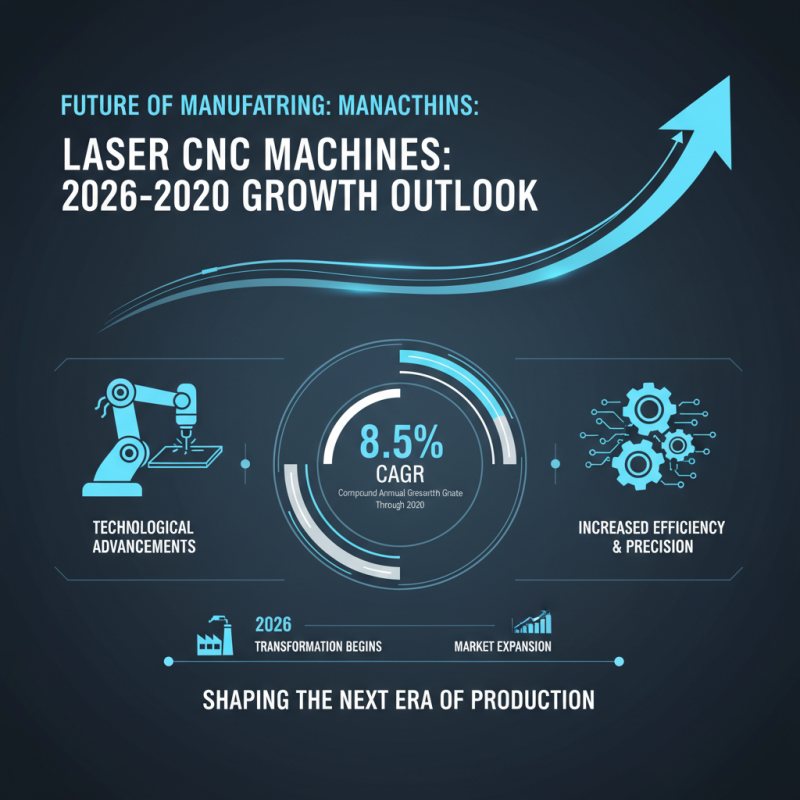

Overview of Laser CNC Machines in 2026

In 2026, laser CNC machines are expected to transform manufacturing processes. The market is projected to grow significantly, driven by advancements in technology. Reports suggest the sector will see a compound annual growth rate (CAGR) of 8.5% through 2030. This growth highlights the increasing efficiency and precision that laser CNC technology brings to various industries.

These machines offer enhanced cutting capabilities. With laser technology, manufacturers can achieve intricate designs with less material waste. Pulse laser systems are becoming popular for their ability to cut complex shapes with high accuracy. However, the high initial investment remains a barrier for several businesses. Many small to medium enterprises struggle to integrate such advanced machinery into their production lines.

The ongoing challenge lies in the upkeep and skill gap. While the technology is impressive, operators require specialized training. A lack of trained personnel could hinder optimal machine utilization. Moreover, maintenance costs can accumulate, impacting overall profitability. As the market evolves, addressing these skills and cost issues will be crucial for businesses looking to thrive in the competitive landscape of 2026.

Key Features to Consider in Laser CNC Machines

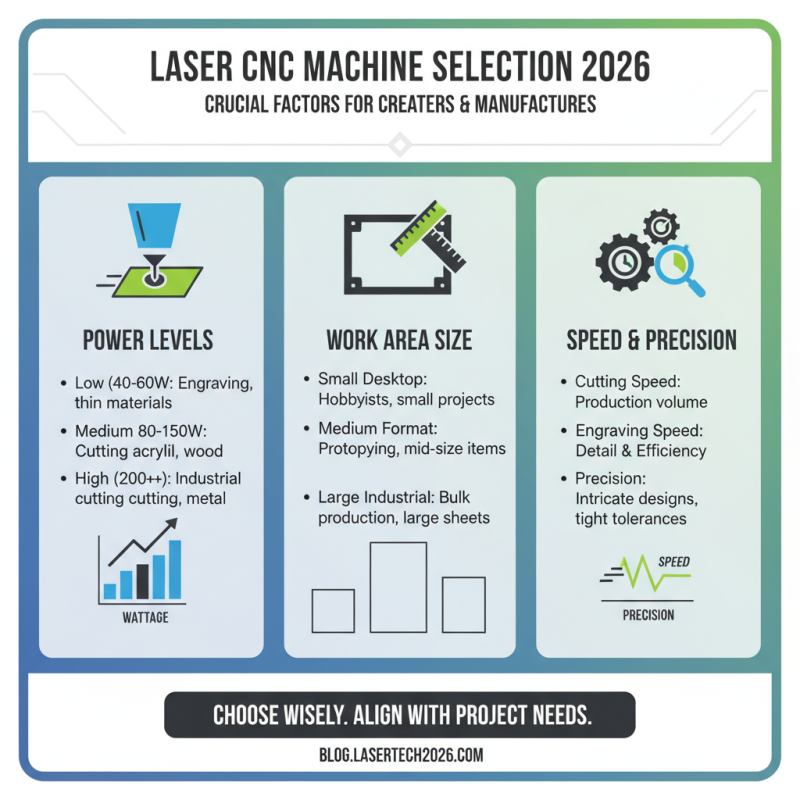

When considering laser CNC machines, several key features play a critical role. The power of the laser is fundamental. Machines typically range from 30W to 150W. Higher wattage delivers faster cutting speeds and cleaner edges. Yet, more power may not always be better. It's essential to assess the materials you plan to work with.

Another crucial aspect is the work area size. Standard sizes can vary significantly. A larger work area allows for bigger projects but might increase the machine's footprint. Ensure your workspace can accommodate the size while maintaining efficiency. Weigh the benefits against the available space.

Tip: Evaluate your typical project sizes before purchasing.

Software compatibility is vital too. Many lasers use proprietary software. Some are limited in capabilities. Others may integrate well with CAD software. Research the software features carefully. A complex interface can complicate workflow unnecessarily.

Tip: Request demonstrations or trials when possible.

Lastly, consider the build quality and customer support. A well-constructed machine may last longer. Poor support can lead to frustration if issues arise. Invest time in reading reviews and networking with users. Reflect on their experiences and lessons learned.

Comparison of Popular Laser CNC Machines for 2026

As we approach 2026, choosing the right laser CNC machine becomes crucial for creators and manufacturers. It's essential to explore the features and specifications of different models. Popular options often include varying power levels, work area sizes, and cutting speeds. Each offer unique advantages and challenges. Some excel in precision, while others stand out for speed. Understanding these factors does help in making informed decisions.

When comparing popular models, consider the material compatibility. Not all machines work equally well with wood, metal, or acrylic. Some struggles with thicker materials. User experience also varies; setups can be complex. Maintenance is another aspect worth considering. Regular upkeep is necessary to keep machines running efficiently. Affordability matters, yet, investing a bit more may lead to better longevity and performance.

In practicing with these machines, errors can occur. Small miscalculations in settings might lead to waste. Even experienced users face issues from occasional software glitches. Learning from mistakes is part of the process. Documenting these hiccups can foster growth and improvement in skills. Ultimately, the right machine aligns with a user’s specific needs and goals.

Applications of Laser CNC Machines Across Industries

Laser CNC machines are revolutionizing various industries with their precision and efficiency. In manufacturing, they are used for cutting metals, plastics, and wood. The laser's focused energy provides accurate cuts, reducing waste and improving production time. This means fewer resources are spent, which is crucial in today’s economic landscape.

In the automotive sector, these machines play a vital role. They are used for creating intricate components that require high precision. The ability to quickly prototype parts speeds up the development process. However, it's essential to keep in mind the initial investment costs. Not every company can afford the latest technology.

In the medical field, laser CNC machines manufacture customized implants and devices. These advancements improve patient outcomes and allow for personalization in treatment. Nonetheless, there are challenges. Regulations can slow the production of new devices. Companies must balance innovation with compliance. The future for laser CNC is bright, but it requires careful consideration and planning.

2026 Top Laser CNC Machines

| Feature | Value | Industry Applications |

|---|---|---|

| Laser Type | CO2 | Woodworking, Signage |

| Max Power | 150W | Metal Cutting, Engraving |

| Table Size | 1300 x 900 mm | Manufacturing, Art |

| Precision | 0.01 mm | Aerospace, Jewelry |

| Cooling Method | Water-cooled | Automotive, Electronics |

| Software Compatibility | AutoCAD, CorelDRAW | Design, Prototyping |

Future Trends in Laser CNC Technology and Innovation

Laser CNC technology is rapidly evolving, driven by innovations in efficiency and precision. One emerging trend is the integration of artificial intelligence. This allows machines to learn and adapt to different materials and cutting techniques. As these systems improve, they promise to reduce waste and enhance productivity on the shop floor.

Another noticeable development is the shift towards eco-friendly solutions. Manufacturers are focusing on using less energy and generating fewer emissions. This not only meets regulatory demands but also appeals to environmentally conscious consumers. However, implementing green technology can be challenging. Companies must balance innovation with cost-effectiveness, which may not always align seamlessly.

User-friendly interfaces are becoming standard in new machines. This is intended to simplify operations for less experienced users. Yet, there is a risk. Over-reliance on automation may lead to skill gaps in the workforce. Continuous training and education are essential. The industry must remain vigilant about maintaining a balance between efficiency and human expertise.

2026 Top Laser CNC Machines: Market Share by Technology Type

This bar chart illustrates the projected market share of various laser technologies in CNC machines for 2026. Fiber lasers are anticipated to dominate the market, reflecting advancements in efficiency and application versatility, followed by CO2 lasers, which remain popular for cutting and engraving materials.

Related Posts

-

Top Laser CNC Trends to Watch in 2025 for Innovative Applications

-

Exploring Laser CNC Innovations at the 2025 China 138th Import and Export Fair

-

Why Laser Cutting Tables are Revolutionizing the Manufacturing Industry: A Deep Dive

-

Top 10 Laser Cutting Tables for Precision and Efficiency in 2023

-

How to Optimize Laser Machining for Precision and Efficiency

-

The Future of Manufacturing with Metal Laser Cutting Technology Explained