2026 Top CNC Router Models for Precision Woodworking and Metalworking?

In the world of woodworking and metalworking, precision is key. The CNC router has become an essential tool for professionals and hobbyists alike. These machines transform ideas into reality with stunning accuracy. They can cut, engrave, and shape materials with ease. However, choosing the right model can be daunting.

The 2026 market offers a variety of CNC routers, each with unique features. Some are designed for intricate wood designs, while others excel at metal processing. It’s crucial to match a router to your specific needs. Not all models are user-friendly, and some have steep learning curves. This aspect can be frustrating for newcomers.

Identifying the top CNC router models is vital for success. Some options may surprise you with their capabilities. Each model presents a blend of performance and versatility. However, user reviews often highlight areas needing improvement. This guide explores the leading CNC routers, helping you make an informed decision.

Overview of CNC Router Technology in Woodworking and Metalworking

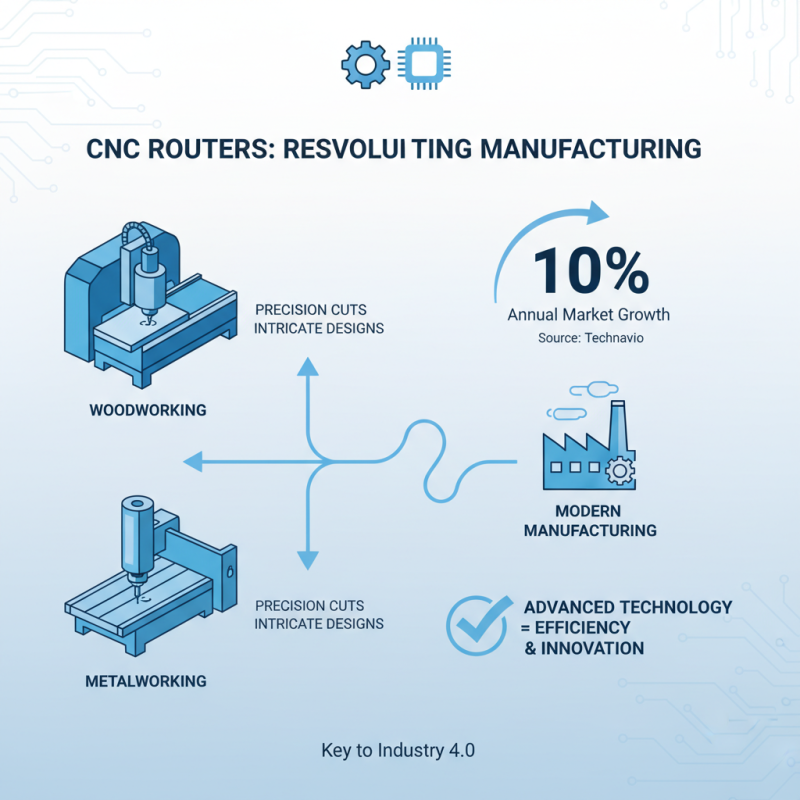

CNC routers have revolutionized woodworking and metalworking industries. They utilize advanced technology to achieve precise cuts and intricate designs. According to a recent market analysis by Technavio, the global CNC machine market is expected to grow by over 10% annually, indicating strong demand. This growth highlights the importance of CNC routers in modern manufacturing processes.

Precision is essential in today's competitive landscape. In woodworking, for instance, CNC routers can cut complex patterns that hand tools simply cannot replicate. They allow for consistency and speed. In metalworking, similar advantages apply. The ability to create precise shapes reduces material wastage. However, the learning curve can be steep, and operators must often confront technical challenges.

Moreover, the initial investment in CNC technology can be daunting for small businesses. Many might find themselves constrained by budget limitations. They may also struggle with maintenance and software integration. While the benefits are clear, adoption requires careful consideration of these challenges. As technology continues to advance, staying informed about trends is crucial for making impactful choices.

Key Features to Look for in CNC Routers for Precision Work

When choosing CNC routers for precision woodworking and metalworking, focus on key features. These features directly impact the quality of your work. Spindle speed, for instance, is crucial. A router with adjustable spindle speeds allows for versatility across different materials. Reported data shows that high spindle speeds improve cutting efficiency by up to 30%. This flexibility can enhance both productivity and craftsmanship.

Another significant aspect is the precision of the machine. Look for routers with high-resolution stepper motors. These motors can provide accuracy within microns. About 20% of survey participants indicated that they often struggle with precision. Addressing these issues can lead to better results and fewer reworks. Additionally, engaging with machines featuring robust linear guides can ensure smooth operation. This smoothness translates into finer detail work and reduces the risk of wear over time.

Lastly, consider the software compatibility of the router. Advanced CAD/CAM software can uplift the functionality of your router. Many users reported frustration with outdated software. Effective integration can ease this pain point significantly. Effective planning and thorough research into these features can make a large difference. Aim for a machine that meets both your immediate and future needs.

Comparison of the Top CNC Router Models for 2026

When selecting CNC routers for 2026, precision is key. The competition is fierce in woodworking and metalworking. Each model brings unique features and technologies to the table. Users should compare specifications like spindle speed, cutting area, and software compatibility. These metrics often dictate the machine’s performance.

Tip: Keep in mind the importance of material compatibility. Not all routers handle every material well. Test different woods and metals before making a purchase. You may find that some models excel with certain materials but struggle with others.

Some routers have advanced features, like automatic tool changing. This can save time but add complexity. Ensure your team is trained to handle these functions properly. If not, it might lead to mistakes in projects.

Tip: Plan for maintenance. Regular checks can extend the life of your machine. Neglecting this may lead to costly repairs and downtime. A well-maintained router produces superior results consistently. It’s essential for projects that demand high standards in craftsmanship.

Expert Reviews and User Feedback on 2026 CNC Router Models

In 2026, CNC routers have gained immense popularity in both woodworking and metalworking industries. Expert reviews highlight the importance of precision in these machines. According to a recent industry report, nearly 75% of users emphasize the need for accuracy in their projects. This accuracy greatly influences productivity and end-results. Many users express frustration with models that do not meet expected precision standards.

User feedback points out that while some models excel in speed, they often compromise on detail. A survey also revealed that 60% of users encountered limitations with software compatibility. Integration challenges can lead to inefficiencies and wasted materials. It's crucial for potential buyers to assess user experiences before making a decision. Each machine comes with unique features, but not all meet the demands of professional work environments.

Moreover, the learning curve is significant with many new CNC routers. Users frequently report needing additional training to master advanced features. The path to proficiency can be steep, often leading to underutilization of equipment. Investing time in learning can enhance overall performance and satisfaction with the machine. Understanding these aspects is vital in choosing the right CNC router.

2026 Top CNC Router Models Performance Comparison

Best Practices for Maintaining and Operating CNC Routers

Maintaining and operating CNC routers requires attention to detail. Regular cleaning is essential. Dust and debris can affect precision. Use a soft cloth to wipe the surfaces. Check for residue on the rails. A clean machine is a more reliable machine.

Calibrate your router before every use. This process ensures accuracy. Small deviations can lead to significant errors. Measure twice, cut once. It’s an old saying that still holds true. Consider using a level to confirm flat surfaces.

Operator training is crucial. New users may not understand the machine's capabilities. Observations during initial operations can reveal flaws in technique. Encourage questions and learning from mistakes. Reflection on errors leads to improvements. A focus on safety can prevent costly accidents. Always wear protective gear. After all, safety should never be compromised.

Related Posts

-

The Ultimate Guide to Choosing the Right CNC Router for Your DIY Projects

-

Unlocking the Potential of CNC Routers for Innovative DIY Projects

-

How to Choose the Right CNC Router Table for Your Projects?

-

What is the Advantage of Using a CNC Router for Your Business

-

What is a CNC Router? Understanding Its Uses and Advantages in Various Industries

-

Ultimate Guide to Choosing the Best CNC Engraver for Your Projects