2026 Best CNC Machining Parts What You Need to Know?

The demand for CNC machining parts is rapidly increasing. According to a report by MarketsandMarkets, the CNC machining market is projected to grow from $63.7 billion in 2021 to $100 billion by 2026. This growth reflects the expanding needs of various industries, including automotive, aerospace, and medical manufacturing.

CNC machining parts stand at the forefront of this trend. These parts offer precision, efficiency, and reliability. In an era where customization is crucial, CNC machining allows for intricate designs. However, not all manufacturers deliver the same quality. Some companies cut corners, which can lead to subpar results.

Consumers must scrutinize quality standards. A responsible approach involves understanding the intricacies of CNC machining. This includes materials used, tolerances, and post-processing techniques. For businesses seeking reliable parts, it’s essential to partner with reputable suppliers. Reflecting on these factors can drive optimal results and enhance industry standards.

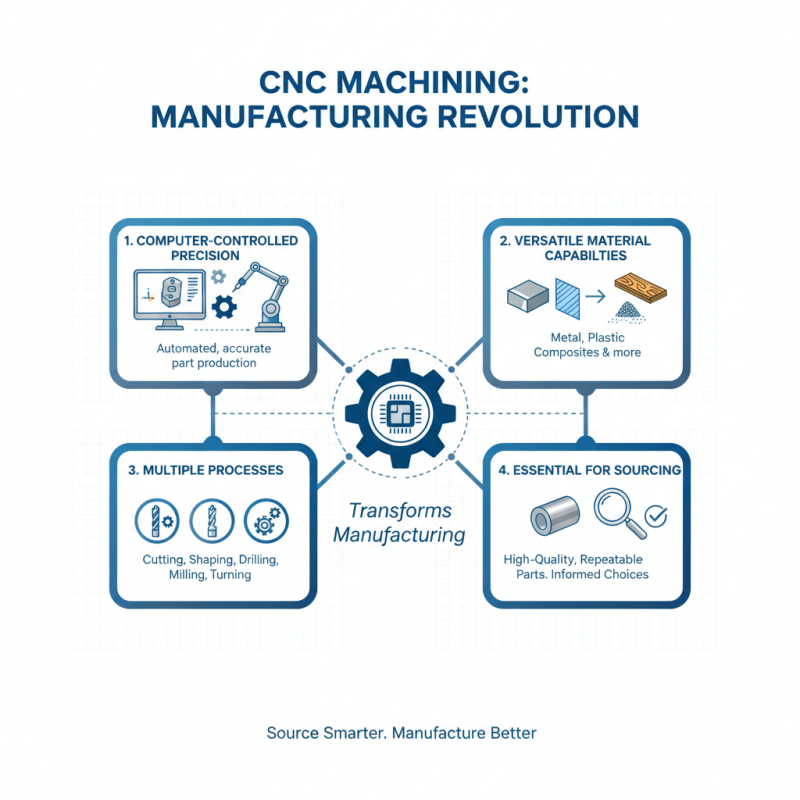

Understanding CNC Machining: A Brief Overview

CNC machining has transformed manufacturing processes. It relies on computer-controlled machines to produce parts with high precision. This technology utilizes various tools to cut, shape, and finish materials like metal and plastic. It is essential to understand the capabilities of CNC machining when sourcing parts.

This process allows for intricate designs, but it requires careful programming. Operators input codes that dictate the movements of the machine. Mistakes in coding can lead to flawed components. Each part produced in CNC machining can have unique specifications. Quality control is crucial in preventing failures and ensuring reliability.

Investment in CNC machining offers numerous advantages. However, it also demands a clear understanding of design limitations. Not all concepts can be easily manufactured. Common issues include tolerances that are too tight or complex geometries. Recognizing these challenges early in the design phase can save time and resources. Emphasizing detail in the planning stages is key to success.

Key Features of the Best CNC Machining Parts in 2026

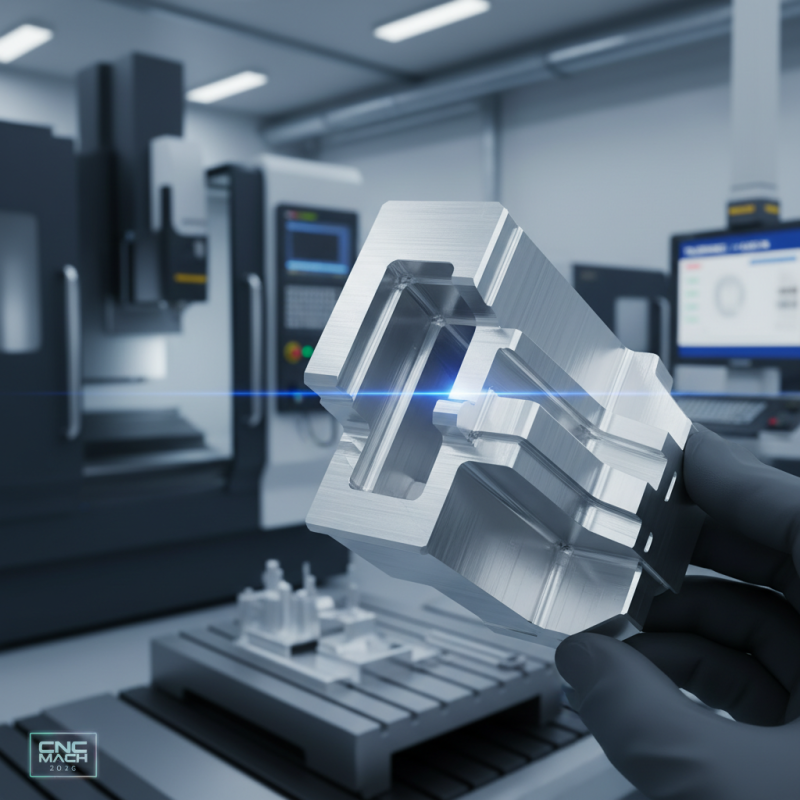

When considering the best CNC machining parts in 2026, key features stand out. Precision is paramount. Parts must be crafted to tight tolerances, often within 0.005 inches. According to a recent industry report, 80% of manufacturers found that precise components significantly enhance product performance. Quality materials are essential. Aluminum alloys and high-grade stainless steel dominate the market. They offer durability while keeping weight low.

Another vital aspect is surface finish. A smooth finish is crucial for reducing friction and wear. Studies show that improved surface quality can extend part life by over 30%. However, achieving this can be challenging. Not every machining process ensures superior finishes. Skilled operators are a must, as mistakes can lead to costly reworks.

Tip: Opt for advanced CNC machines that include intelligent software. This technology can help minimize human errors. Evaluating your machining needs early can save time and resources later. Overlooking this might result in parts that don’t meet the desired specifications. It's crucial to weigh trade-offs between speed and quality during production. Consider all elements carefully for optimal results.

Materials Used in CNC Machining Parts: What to Choose?

Choosing the right materials for CNC machining parts can significantly impact performance and durability. Common materials include aluminum, steel, and plastic. Aluminum is lightweight and offers good machinability. It is often used in aerospace and automotive applications. Steel, on the other hand, provides strength and resilience, making it ideal for structural components.

Plastic materials are great for prototypes and low-stress applications. They are easy to machine and often cheaper. However, they may not withstand heavy loads. Reflecting on material choice is essential. Some users may prioritize durability over cost, while others may choose lightweight options for efficiency.

Mistakes can happen during the selection process. Failing to consider the specific operating environment can lead to material degradation. For example, moisture can affect certain plastics, while extreme temperatures may weaken some metals. Each project requires careful analysis of expected conditions. Being aware of these factors will lead to better decisions in CNC machining.

2026 Best CNC Machining Parts: What You Need to Know? - Materials Used in CNC Machining Parts: What to Choose?

| Material Type | Characteristics | Applications | Cost per kg |

|---|---|---|---|

| Aluminum 6061 | Lightweight, good corrosion resistance, good machinability | Aerospace, automotive, marine parts | $3.00 |

| Stainless Steel 316 | Excellent corrosion resistance, good weldability, durable | Food processing, chemical industry, medical devices | $5.00 |

| Carbon Steel | High strength, relatively low cost, good machinability | Construction, automotive parts, tools | $2.00 |

| Plastic (ABS) | Good impact resistance, lightweight, easy to machine | Consumer goods, housing components, prototypes | $1.50 |

| Titanium | High strength-to-weight ratio, excellent corrosion resistance | Aerospace, biomedical, marine applications | $25.00 |

Top Industries Benefiting from CNC Machining in 2026

In 2026, CNC machining continues to shape various industries. The automotive sector stands out as a major beneficiary. Precision parts are crucial here. Manufacturers rely on CNC machines for intricate designs. These machines ensure consistency and speed, vital in a competitive market.

Aerospace is another field reaping benefits. Components require high precision and durability. CNC machining meets these demands effectively. However, challenges exist. Costs can escalate if machines malfunction. Additionally, skilled operators are needed to ensure quality. Training is essential but often overlooked.

Medical devices are rapidly evolving, with CNC machining at the forefront. Customized parts cater to specific patient needs. This personalization improves outcomes but also poses difficulties. Regulatory compliance can be complex. Each component must meet stringent safety standards. Balancing innovation with regulations is an ongoing challenge.

Top Industries Benefiting from CNC Machining in 2026

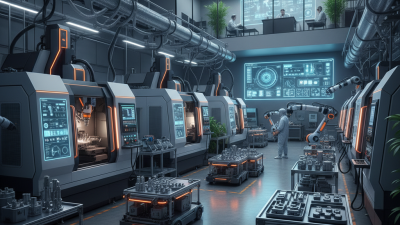

Trends Shaping the Future of CNC Machining Parts Production

The CNC machining industry is experiencing a significant transformation. New technologies are shaping production dynamics. Data from industry reports indicate that the market is expected to grow at a CAGR of over 6% from 2023 to 2028. This trend highlights the increasing demand for precision and efficiency.

One notable trend is the rise of automation in the production process. Automated systems can enhance accuracy and reduce waste. Experts emphasize that this transition is crucial. However, companies must invest in training staff to handle new technologies efficiently.

Tip: Regularly assess your workforce's skill set. Upgrading skills is essential for adapting to these changes.

Another key area is the integration of advanced materials. Lightweight composites are becoming more prominent in part production. They offer durability while reducing the weight of finished products. Yet, sourcing these materials can be challenging. There's often a trade-off between cost and quality.

Tip: Stay informed about material advancements. Being early adopters can provide a competitive edge.

As trends evolve, companies must remain adaptable. Those that embrace change will likely succeed. The landscape is vibrant but also poses challenges that require careful navigation.

Related Posts

-

2025 Top 10 CNC Machining Trends Transforming Manufacturing Industry

-

Top Laser Machining Trends for 2025: Innovations and Applications You Can't Miss

-

Top 10 Stainless Steel Laser Cutting Innovations to Watch in 2025

-

How to Set Up Router Tables for Perfect Woodworking Projects

-

Unlocking Creativity with Custom Laser Cutting Techniques for Unique Designs

-

2026 Top Laser CNC Machines What You Need to Know?